How to Choose the Best Hydraulic Hose for Sale?

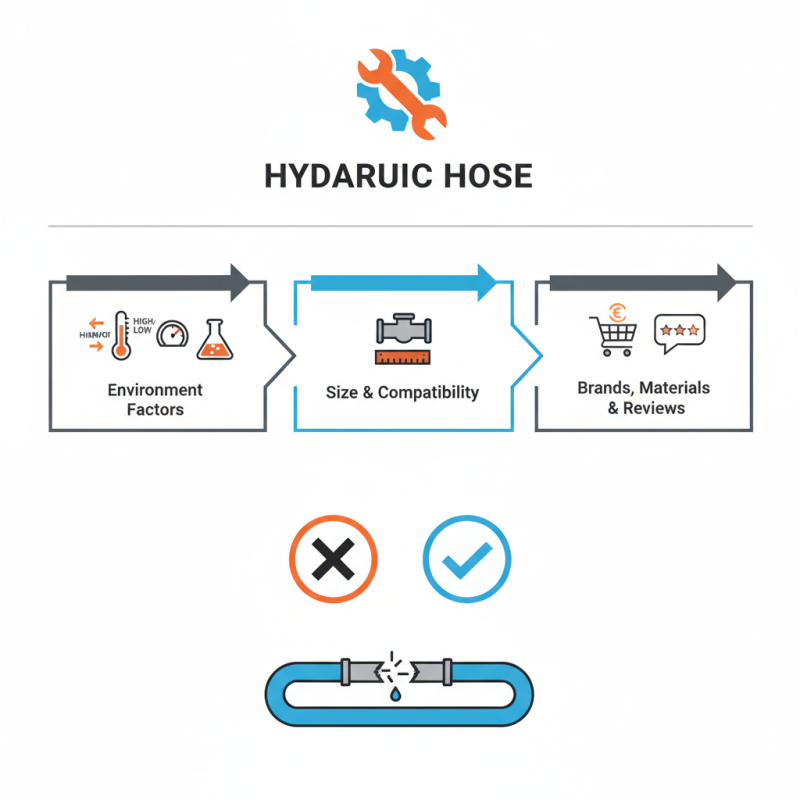

Choosing the right hydraulic hose for sale can significantly impact your project’s success. With various options available, it’s essential to understand your specific needs. Different applications require different specifications. A poorly chosen hose can lead to leaks and failures, causing delays.

Consider the environment where the hose will operate. Factors such as temperature, pressure, and exposure to chemicals all matter. Proper assessment of these elements is crucial. Avoid underestimating the importance of size and compatibility with existing equipment. An ill-fitting hose can result in significant inconveniences.

As you search for hydraulic hoses for sale, take the time to compare brands and materials. Not every product on the market meets high standards. Some sellers may offer tempting prices, but reliability often costs more. Reflect on customer reviews and warranty options. Remember, not all affordable solutions are the best choices for your needs.

Understanding Hydraulic Hose Specifications and Standards

When selecting a hydraulic hose, understanding specifications is crucial. These details can affect performance and safety. Look at the pressure rating. It indicates how much pressure the hose can handle. Choosing a hose with insufficient pressure rating can lead to failure. It’s important to assess working conditions.

Material choice impacts durability. Common options include rubber and thermoplastic. Each has unique strengths. Rubber hoses are flexible. Thermoplastic can resist certain chemicals. Consider environmental factors too. Extreme temperatures can affect hose lifespan.

Tips: Always check the hose's compatibility with fluids. Inspect for wear regularly. A worn hose may look fine but can fail unexpectedly. Keep in mind that every application is different. Assess your needs carefully. It's tempting to save money, but a poor choice can cost more in the long run. Making informed decisions is vital. Consider consulting experts if uncertain.

Hydraulic Hose Specification Overview

This chart displays the various specifications for hydraulic hoses, including hose diameter, pressure rating, temperature range, bend radius, and weight. Understanding these specifications is crucial when selecting the best hydraulic hose for your needs.

Identifying the Right Hose Material for Your Application

Choosing the right hose material is crucial for any hydraulic application. Different materials offer unique advantages and limitations. Rubber hoses are versatile and flexible. They can handle a wide range of temperatures and pressures. However, they may not perform well in harsh environments, especially where chemicals are involved. Reports suggest that over 30% of hydraulic failures can be traced back to inadequate hose material selection.

On the other hand, thermoplastic hoses are resistant to abrasion and chemicals. They are lighter and easier to handle. However, they may not endure high temperatures as well as rubber hoses do. A study indicates that using the wrong hose material can lead to a productivity loss of up to 20%.

Metal hoses, while durable, can be costly. They are often heavy and may require special fittings. It's vital to assess the working environment. Consider factors like temperature, pressure, and chemical exposure. Even minor oversights in material selection can result in significant safety risks. Regular reviews of current hose performance can help identify any inadequacies. This proactive approach not only ensures safety but also improves operational efficiency.

Evaluating Pressure Ratings and Temperature Compatibility

When selecting a hydraulic hose, pressure ratings are crucial. They indicate the maximum pressure the hose can handle. Industry standards suggest that hoses must be rated at least 1.5 times the maximum operating pressure. For instance, a hydraulic system operating at 2500 psi should use a hose rated for 3750 psi. Failure to consider this can lead to hose rupture.

Temperature compatibility is another key factor. Different materials respond differently to heat. A report by the Hydraulic Institute states, "Most rubber hoses can handle temperatures between -40°F and 212°F." However, some synthetic options resist higher temps. Using a hose in extreme conditions can lead to a shortened lifespan or accidents. Understand the operating environment, but remain cautious. Mixing hoses with incompatible temperature ratings can create severe challenges.

Consider the specifics of your application. What pressure will you typically operate at? What are the temperature extremes? These details guide your choice. Many overlook this, assuming any hose will suffice. This oversight could be costly. Ensure your selections meet both the pressure and temperature requirements to avoid future issues.

Selecting the Appropriate Hose Size and Length

Choosing the right size and length for a hydraulic hose is crucial for optimal performance. Many industry reports indicate that improper sizing leads to inefficiencies. A study from the Hydraulic Institute found that 15% of system failures are due to using the wrong hose length. This can cause excessive pressure drops and increased strain on pumps.

When determining the size, consider the diameter. A hose that is too small can restrict flow. This restriction may result in overheating and increased wear. Conversely, a hose that is too large causes turbulence. Turbulence reduces efficiency and can lead to pressure loss. The National Fluid Power Association suggests using hoses that match equipment specifications precisely.

Length is equally important. Longer hoses may kink or bend, affecting performance. On average, a three-foot excess hose length can reduce capacity by 10%. This is significant in high-pressure applications. Some users overlook these details, leading to costly mistakes. It is essential to examine environmental factors, such as temperature and fluid type, when selecting the hose. Think carefully about your specific needs.

How to Choose the Best Hydraulic Hose for Sale? - Selecting the Appropriate Hose Size and Length

| Hose Type | Inner Diameter (inches) | Length (feet) | Pressure Rating (PSI) | Material |

|---|---|---|---|---|

| Rubber Hydraulic Hose | 1 | 50 | 3000 | Rubber |

| Steel Wire Braided Hose | 0.75 | 100 | 4000 | PVC |

| Thermoplastic Hose | 0.5 | 75 | 2500 | Thermoplastic |

| Wire-Reinforced Hose | 1.25 | 30 | 3500 | Composite |

| Heat Resistant Hose | 1 | 20 | 3000 | Silicone |

Considering Fittings and Accessories for Optimal Performance

When choosing a hydraulic hose, fittings and accessories play vital roles. The right fittings ensure a tight connection. An improper fit can lead to leaks and accidents. Check compatibility with your hose specifications. A mismatch here can be costly and dangerous.

Consider the materials of fittings. Some materials are more resistant to corrosion. Others may not hold up under extreme pressures. Think about your working environment. If it is particularly harsh, choose accordingly. Accessories like clamps and adapters are equally important. They provide additional support and flexibility. Neglecting these can lead to performance issues.

Remember, even top-quality hoses can fail with the wrong accessories. Performance can be impacted negatively. Regularly check your hose setup for wear and tear. Replace faulty parts immediately. It's a small task that can save you headaches later. Assessing every component helps ensure optimal performance. Each choice counts.