How to Choose the Right Plastic Injection Mold for Your Project?

Choosing the right Plastic Injection Mold is crucial for any manufacturing project. In 2023, the global plastic injection molding market was valued at over $200 billion. This industry continues to grow as demand for efficient and high-quality production increases.

Selecting the correct mold can impact product quality, production speed, and cost-effectiveness. Reports show that 30% of project delays stem from poor mold choices. Small manufacturers often overlook the importance of mold material and design, leading to costly mistakes.

Understanding your project requirements is essential. Are you aiming for high-volume production or a single custom piece? Factors like complexity and precision directly influence mold selection. Always consider the trade-offs in costs versus quality. This decision can define the success of your project or result in frustration.

Understanding the Basics of Plastic Injection Molding

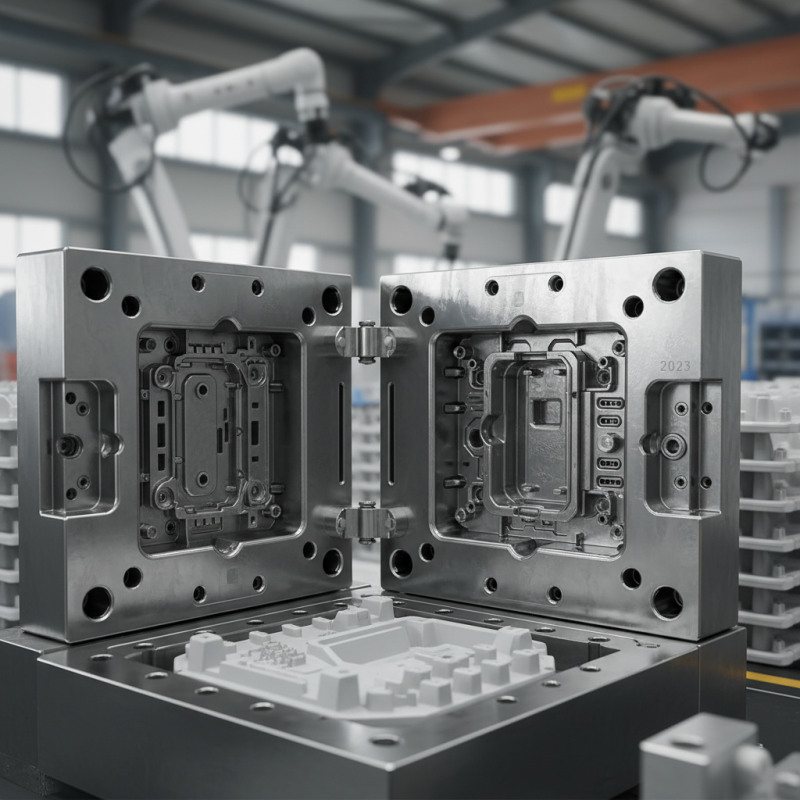

Understanding the basics of plastic injection molding is crucial for a successful project. This process involves injecting molten plastic into a mold. The mold is made of steel or aluminum and shaped to create the desired part. The temperature and pressure during injection affect the final product’s quality. Any miscalculation can lead to defects, such as warping or incomplete filling.

A good design must consider various factors. Wall thickness is one of them. It should be consistent to avoid uneven cooling. Draft angles help parts release easily from the mold. Not all designs are perfect, and flaws can appear during the first production runs. Testing prototypes can reveal issues that need addressing. Ignoring these aspects can result in wasted materials and time.

Selecting the right mold might seem straightforward, but it requires careful thought. The complexity of the part influences mold choice. Intricate designs mean specialized molds, which can be costly. Sometimes, simpler designs are more effective. Engineers must weigh the importance of detail against production efficiency. A balance is necessary, but achieving it isn't always easy.

Identifying Project Requirements for Mold Selection

Choosing the right plastic injection mold starts with clear project requirements. Understanding the specifics of your product is crucial. Consider the type of plastic you intend to use. Each material has unique properties that affect how the mold performs. For instance, some plastics might require higher temperatures or specific cooling times.

Next, think about the design of the part. Complex shapes may need more intricate molds. Simpler designs can often be accommodated with standard molds. However, a complex design can lead to challenges, such as prolonged production times. Reflect on the trade-offs. Will the complexity justify the costs involved? Analyzing this early can prevent costly mistakes later on.

You should also consider production volume. High volumes justify investing in a more expensive, durable mold. Lower volumes might make a less expensive option more appealing. However, the mold's longevity is important. A cheap mold may wear out quickly, leading to inconsistencies in your products. Balancing cost and quality is key. Being clear about your requirements now will help you make the best decision for your project.

Evaluating Material Options for Your Injection Mold

When evaluating material options for your injection mold, consider the specific requirements of your project. Different materials offer varying strengths, durability, and temperature resistance. For example, steel molds are robust and long-lasting but may be expensive. On the other hand, aluminum molds are lighter and cheaper but may wear out faster. Finding the right balance between cost and longevity can be tricky.

Another crucial factor is the intended application of the mold. Some projects may require intricate designs that demand higher precision. In such cases, materials that allow for fine details should be prioritized. However, high-precision molds often come with higher costs. This can prompt a difficult choice between budget limitations and quality needs.

Keep in mind the potential for unforeseen challenges. The choice of material can influence production speed and the final product's finish. In some instances, a less durable material may lead to extensive rework. Reflecting on past projects can help avoid these pitfalls, ensuring you choose wisely for your current endeavor.

Assessing Manufacturer Capabilities and Experience

Choosing the right plastic injection mold can be challenging. Assessing the manufacturer's capabilities is crucial. Look for their experience in your specific industry. A manufacturer with a strong background in your application can provide valuable insights.

Examine their portfolio. What projects have they completed? Solid examples of similar work can boost your confidence. Ask about their production processes. Are they using modern technology? Efficient methods can lead to better quality molds.

It's also important to discuss their design capabilities. Do they have an in-house design team? This can facilitate smoother communication and quicker adjustments. Be aware of potential gaps in their skills. A manufacturer without experience in complex shapes or unique materials may struggle with your project. Aim for transparency. Engage in discussions about challenges and improvements. Understanding their processes could save you time and money in the long run.

Cost Considerations in Plastic Injection Mold Development

Cost considerations play a critical role in plastic injection mold development. The process can range significantly in price. According to industry reports, the average cost of a high-quality mold can be between $5,000 to $100,000. This wide range reflects factors such as complexity and material type. Moreover, advanced features or custom designs can escalate costs by 25% or more.

When evaluating costs, consider the long-term production needs. A cheaper mold might seem appealing, but it can lead to increased maintenance and shorter lifespan. For instance, molds made from lower-grade steel may wear out quicker. This could ultimately increase production downtime and costs. Industry data suggests that using high-quality materials can reduce repair costs by as much as 30% over time.

Another cost driver is the production volume. If high volumes are expected, investing in a durable mold is wise. Molds designed for repeated use may have a higher initial cost but save money in the long run. Conversely, low-volume projects might benefit from simpler designs, despite the risk of less durability. Evaluating these aspects will influence the overall project budget and timeline.