The Comprehensive Handbook for Mastering Printing Labels Techniques

In today's fast-paced business environment, the importance of effective product labeling cannot be overstated. According to a recent report by Smithers Pira, the global market for labels is projected to reach $204 billion by 2023, driven primarily by the growth in e-commerce and the increasing demand for sustainable labeling solutions. As companies strive to enhance brand visibility and ensure regulatory compliance, mastering various printing labels techniques has become essential. This comprehensive handbook delves into alternative methods for printing labels, exploring innovative technologies and materials that can elevate labeling efficiency and sustainability. Whether you're a seasoned professional or a newcomer in the industry, understanding these alternatives will empower you to navigate the complexities of label printing and stay ahead in an increasingly competitive landscape.

Understanding the Different Types of Printing Labels for Your Needs

When it comes to printing labels, understanding the different types available is crucial for meeting various business and organizational needs. From shipping labels to file-folder tags, the right label type can significantly impact efficiency and branding. As businesses evolve, they are turning to innovative label printing solutions that not only save money but also deliver high-quality results. The demand for versatile label makers is on the rise as companies seek to streamline processes and maintain a professional appearance.

Label printers are getting smarter and more versatile, offering users the flexibility to create personalized labels quickly and efficiently. Whether you're a small business owner looking to enhance your branding or an individual trying to keep your home or workspace organized, the right label printer can help achieve those goals. New technologies are making it easier than ever to print everything from nutritional labels to shipping tags, allowing consumers and businesses alike to choose the most effective and suitable labels for their needs.

Essential Techniques for Designing Professional-Quality Labels

Designing professional-quality labels involves understanding the essential techniques that can significantly enhance the visual appeal and functionality of your products. According to a recent report from the Label Industry Global Status Report, the global label market was valued at approximately $45 billion in 2022 and is projected to grow steadily as businesses increasingly recognize the importance of high-quality packaging. A well-designed label not only attracts consumer attention but also communicates brand values effectively.

Tip: Utilize high-resolution images and maintain a coherent color scheme that aligns with your brand identity to create a lasting impression. Research indicates that colors can increase brand recognition by up to 80%. Therefore, choosing the right colors can make a substantial difference in label effectiveness.

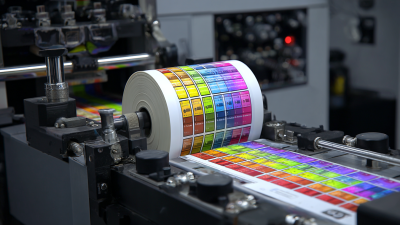

Another critical aspect is the choice of materials and printing techniques. Various substrates, such as paper, vinyl, and polyester, offer distinct benefits depending on the intended use of the label. A study from Smithers Pira highlights that digital printing technologies are expected to account for 30% of the label market by 2025, emphasizing the shift towards personalized and short-run products.

Tip: When selecting printing technology, consider the production volume and the required durability of the label. This can save costs and improve quality, ensuring your labels withstand handling and environmental factors.

Choosing the Right Materials for Effective Label Printing

Choosing the right materials for effective label printing is crucial to achieving high-quality, durable labels. Recent industry reports indicate that the global label printing market is expected to reach $42.8 billion by 2026, driven by increasing demand for product identification and branding. Selecting appropriate materials can significantly impact the lifespan and visibility of labels, making it essential to understand the available options. For instance, durable synthetic materials like polypropylene and polyester are widely favored for their resistance to water and chemicals, ideal for products that are exposed to harsh environments.

Tip: Always consider the end-use environment of your labels. If they will be exposed to moisture or varying temperatures, choosing waterproof and temperature-resistant materials can enhance their longevity and effectiveness.

Tip: Always consider the end-use environment of your labels. If they will be exposed to moisture or varying temperatures, choosing waterproof and temperature-resistant materials can enhance their longevity and effectiveness.

Furthermore, printing technology also plays a vital role in the material selection process. For example, while thermal transfer printing is excellent for producing high-resolution graphics on synthetic labels, direct thermal printing may be more suitable for short-term applications. According to a 2021 report by Smithers Pira, businesses that optimize their printing techniques alongside material selection can see a reduction of up to 20% in printing costs and an increase in productivity. This balance between material quality and printing technology is key to maximizing label performance.

Tip: Always test your labels under real-world conditions before a full production run to ensure optimal adhesion and durability.

Common Mistakes to Avoid in Printing Labels and How to Fix Them

When it comes to printing labels, avoiding common mistakes can save both time and resources. One prevalent issue is the misalignment of text and images, which can lead to unsightly labels that don't convey the intended message. This often occurs due to improper setup in the label design software or using the wrong template size for your printer. Ensuring that your software settings correspond closely to your printing specifications can significantly reduce these errors.

Another frequent pitfall involves color mismatches. This can be particularly frustrating when labels do not print as designed, leading to confusion and even brand inconsistency. To mitigate this risk, it’s critical to perform test prints before committing to a large batch. Additionally, using high-quality label printing software can help streamline the design and printing process, providing better color calibration options and print previews that highlight any potential issues before they occur. Taking these precautions can help you create professional-looking labels that resonate with your audience.

Common Mistakes in Printing Labels and Their Impact

Advanced Tips for Achieving Consistent Label Quality and Precision

When it comes to printing labels, achieving consistent quality and precision is crucial for any business. To master this skill, start with selecting the right materials. Choose high-quality label stock that suits your printing method, be it inkjet, laser, or a specialized label printer. The selection of adhesive is also vital; it should complement the surface it adheres to while ensuring durability over time.

Experimenting with different finishes, such as matte or glossy, can elevate the final product and enhance visual appeal.

Equally important is the calibration of your printing equipment. Regular maintenance and adjustments can vastly improve print quality. Ensure your printer settings align with the type of label material you are using. This precision helps avoid common issues like smudging or misalignment. Additionally, utilizing design software that allows for exact measurements and alignments will help in creating labels that are not only aesthetically pleasing but also functional. By implementing these advanced tips, you can elevate your labeling process and create products that effectively represent your brand's commitment to quality.

Related Posts

-

Unlocking the Power of Best Food Packaging Label Printers with In Depth Technical Specifications and User Guide

-

Essential Checklist for Choosing the Best QR Code Label Printer for Your Business Needs

-

The Definitive Guide to Mastering Print Adhesive Labels for Your Business

-

Unleashing Growth Opportunities for Packaging Printers at the Record Breaking Canton Fair 2025

-

Top 10 Package Label Printer Manufacturers from China at the 137th Canton Fair

-

Excellence in Digital Label Printing Crafted in China for Global Impact