Excellence in Digital Label Printing Crafted in China for Global Impact

The landscape of Digital Label Printing is rapidly evolving, driven by advancements in technology and shifting consumer demands. According to a recent report by Smithers Pira, the global market for digital labels is projected to reach $29 billion by 2025, reflecting a compound annual growth rate of 12.5%. This significant growth highlights the increasing reliance on digital solutions for efficiency and customization in packaging. China, as a manufacturing powerhouse, plays a pivotal role in this transformation, leveraging state-of-the-art printing technologies to produce high-quality labels that cater to diverse global markets. As brands strive for excellence in their packaging solutions, the pursuit of alternatives, such as eco-friendly materials and innovative printing techniques, becomes paramount. The synergy between China's manufacturing capabilities and the demand for digital innovation positions the nation as a leader in delivering impactful digital label solutions worldwide.

Emerging Trends in Digital Label Printing: A Global Perspective

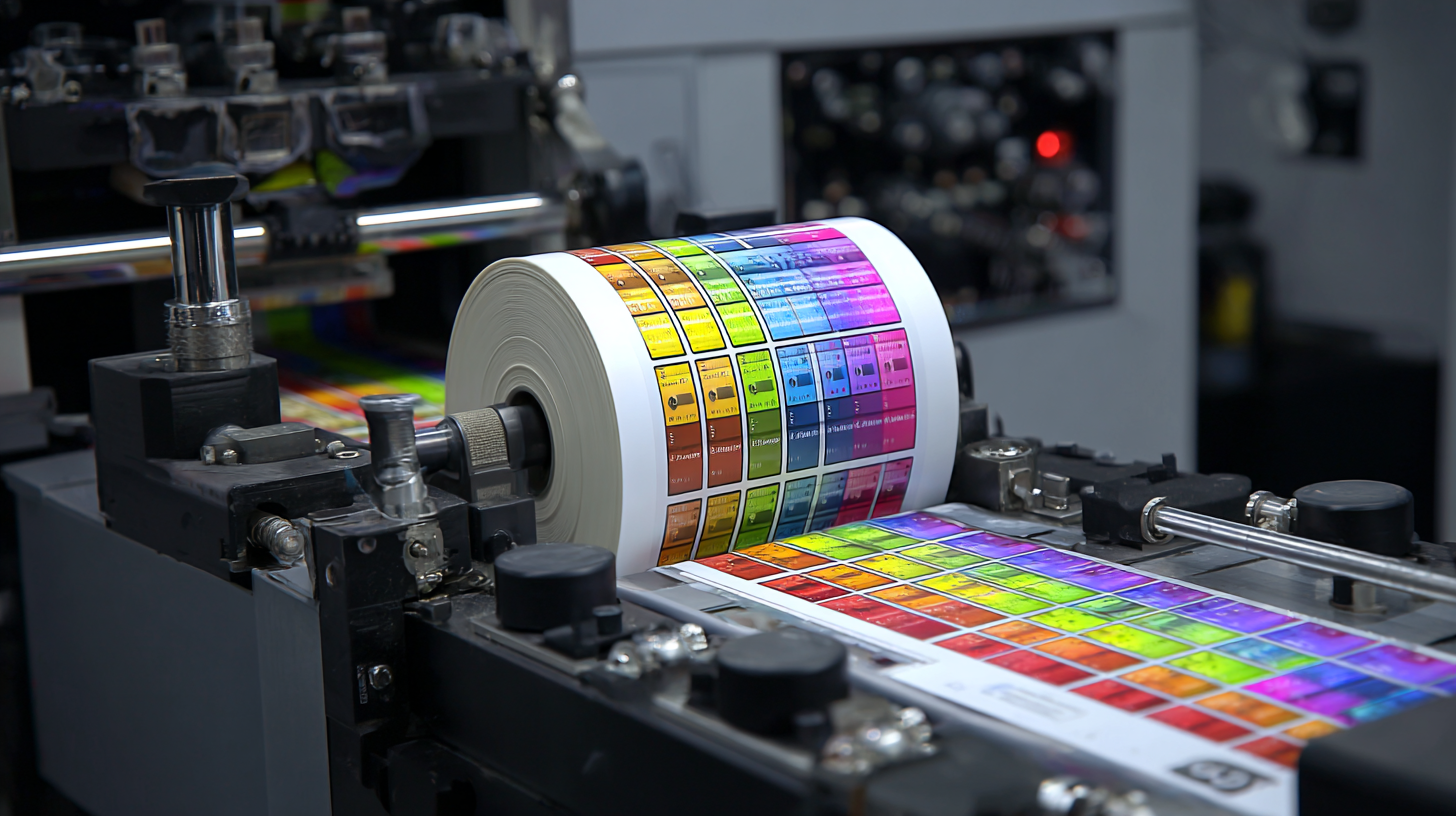

In recent years, digital label printing has experienced significant evolutions, driven by technological advancements and changing market demands. Emerging trends indicate a shift toward personalized packaging, as brands seek to connect with consumers on a deeper level. From vibrant colors to intricate designs, digital printing allows for customization that traditional methods cannot match. As companies increasingly embrace these innovations, the ability to produce short runs of labels with rapid turnaround times becomes essential in maintaining competitive advantage.

Another noteworthy trend in digital label printing is the emphasis on sustainability. As consumers become more environmentally conscious, brands are prioritizing eco-friendly materials and practices in their packaging solutions. This shift not only caters to consumer preferences but also aligns with global initiatives aimed at reducing waste and promoting sustainable production methods. With these trends gaining momentum, companies that leverage digital label printing effectively can create a lasting impact both locally and globally, reflecting a commitment to quality and sustainability while addressing the diverse needs of their clientele.

The Impact of Chinese Innovation on Digital Label Quality and Efficiency

The digital label printing industry is witnessing a remarkable transformation, largely driven by innovative technologies emerging from China. According to a report by Smithers Pira, the global digital label market is expected to grow at a compound annual growth rate (CAGR) of 6.7%, reaching USD 25 billion by 2025. China, as a manufacturing powerhouse, is leading this growth through significant investments in advanced printing technologies, which enhance both the quality and efficiency of labels produced.

Chinese manufacturers are leveraging cutting-edge technologies such as digital printing presses and high-resolution inkjet systems to meet the increasing demand for customizable and short-run labels. A study by IHS Markit highlights that over 40% of label producers in Asia are now adopting digital printing capabilities, improving production times by up to 50% compared to traditional methods. This advancement not only allows for greater design flexibility but also reduces waste, aligning with the growing emphasis on sustainability in packaging solutions.

Furthermore, the integration of artificial intelligence in the digital printing process has revolutionized quality control, enabling real-time monitoring and adjustments. With data from Technavio indicating that automation in label printing can lead to a 30% increase in operational efficiency, it’s clear that Chinese innovations are setting new benchmarks for digital label quality and efficiency on a global scale. As these advancements continue to shape the industry, the collaborative efforts between Chinese manufacturers and international clients will further enhance the quality of packaging solutions worldwide.

Excellence in Digital Label Printing Crafted in China for Global Impact

| Dimension | Value |

|---|---|

| Annual Digital Label Production Capacity | 500 million labels |

| Average Printing Speed | 200 meters per minute |

| Market Share (Digital Labels) | 30% in Asia |

| Investment in R&D (2023) | $200 million |

| Innovation Index Score | 85/100 |

| Average Label Printing Resolution | 1200 dpi |

| Sustainability Certifications | ISO 14001, FSC |

| Customer Satisfaction Rate | 90% |

Understanding the Market Growth: Statistics Behind the Digital Label Industry

The digital label industry is witnessing remarkable growth, projected to increase from $2.69 billion in 2023 to $10 billion by 2032, with a compound annual growth rate (CAGR) of 15.71%. This surge is indicative of a rising demand for customizable and efficient labeling solutions across various sectors, particularly in food and consumer goods. As businesses seek to enhance their brand visibility and consumer engagement, the adoption of digital label printing is becoming a crucial factor for success.

Tips for businesses looking to capitalize on this growth include investing in innovative digital printing technologies that offer flexibility and speed. Utilizing data-driven strategies can lead to more targeted marketing efforts and improved customer experiences. Additionally, engaging in industry collaborations, such as food quality and safety conferences, can provide valuable insights into evolving market trends and regulatory requirements, thereby enhancing operational efficiency.

Moreover, the pressure-sensitive label market is also on an upward trajectory, growing from $11.5 billion in 2023 to $18.98 billion by 2032. Companies must adapt to changing consumer preferences by adopting sustainable labeling practices and leveraging digital platforms for effective product traceability. By staying ahead of these trends, businesses can ensure they remain competitive in the dynamic landscape of the digital labeling market.

Sustainability in Digital Printing: Eco-Friendly Practices from China

Sustainability is becoming a critical focus in the digital label printing industry, particularly as companies worldwide look for eco-friendly practices to reduce their environmental impact. In a recent report by Smithers Pira, the global market for digital labels is projected to reach $30 billion by 2025, with sustainability driving innovation and investment. China, as a leading manufacturer, is at the forefront of this movement, implementing advanced eco-friendly technologies in their printing processes.

One notable practice involves the use of water-based inks, which not only reduce VOC emissions but also minimize the environmental footprint associated with solvent-based inks. According to a study by the Environmental Protection Agency, water-based inks can reduce hazardous pollutants by up to 70%. Furthermore, Chinese manufacturers are increasingly adopting recyclable and biodegradable substrates, which contribute to waste reduction and support the circular economy. With around 80% of label converters in China now integrating sustainable practices, the country is poised to set a global benchmark for eco-conscious digital printing solutions that not only cater to diverse market demands but also promote a cleaner, greener future.

Technological Advances Shaping the Future of Digital Label Production

In the realm of digital label printing, technological advancements are revolutionizing production methods and quality standards. With cutting-edge technologies such as high-speed inkjet printing and automation software, manufacturers in China are not just meeting international demand but setting new benchmarks in efficiency and precision. These innovations allow for rapid prototyping and customization, catering to the diverse needs of global clients while maintaining exceptional quality.

Tip: Embrace Automation

To maximize production efficiency, consider integrating automation into your printing processes. Automating repetitive tasks not only speeds up operations but also reduces the likelihood of human error, ultimately leading to higher quality labels.

Additionally, the adoption of environmentally friendly materials and processes is shaping the future of digital label printing. Brands are increasingly aware of their ecological footprint, prompting manufacturers to innovate sustainably. This shift not only appeals to eco-conscious consumers but also boosts brands' competitiveness in a fast-evolving market.

Tip: Invest in Sustainable Materials

Choosing eco-friendly substrates can elevate your brand’s image and appeal to a growing market segment that values sustainability. This investment not only benefits the environment but can also lead to cost savings in the long run, as operating efficiently becomes more vital.