What is a Food Label Printer and How Does it Work?

Food Label Printers play a crucial role in the food industry. According to a recent report by Research and Markets, the global food labeling market is expected to reach $38 billion by 2025. This growth underscores the importance of efficient labeling systems. These printers provide essential information about ingredients, allergens, and nutritional facts.

Consumers today are more informed. They seek clarity in what they eat. A Food Label Printer enables manufacturers to meet these demands efficiently. The technology simplifies the labeling process and enhances accuracy. Mistakes in labeling can lead to health risks and financial losses.

However, not all printers are created equal. Some may lack the versatility needed for diverse products. Others might not integrate well with existing systems. This highlights the importance of choosing the right Food Label Printer. Ensuring compliance and clarity in labeling is paramount. The wrong choice can lead to confusion and missed opportunities. Thus, understanding the workings of food label printers is essential for any food business.

What is a Food Label Printer?

A food label printer is a specialized device used to produce labels for various food products. These printers are essential in the food industry. They ensure that all necessary information, such as ingredient lists, nutritional facts, and allergen warnings, is clearly displayed. According to recent industry reports, around 30% of recalls are due to mislabeling. This highlights the importance of accurate information on food labels.

The operation of a food label printer typically involves digital technology. Users can input required data through software connected to the printer. Many models offer features like barcode printing and custom design options. It's reported that 80% of businesses see improved compliance after integrating label printers. However, not all printers meet industry standards or offer high-quality outputs. Some may produce labels that fade or smear easily, leading to additional costs and waste.

Many companies face challenges when selecting a food label printer. Price is often a significant factor. Some might opt for cheaper models, but this can lead to more problems. Research shows that investing in a reliable printer pays off in the long run. Many businesses still struggle with the learning curve involved in using these devices. The balance between cost and performance remains a topic of debate.

What is a Food Label Printer and How Does it Work?

| Feature | Description | Benefits |

|---|---|---|

| Print Technology | Thermal transfer or direct thermal printing | High-quality prints with durability, no ink needed |

| Label Materials | Compatible with various materials like paper, film, and synthetic | Flexible options for diverse products and environments |

| Connectivity | USB, Ethernet, and wireless options | Easy integration with existing systems and remote printing |

| Software Compatibility | Supports label design software and barcoding applications | Increased efficiency in label production |

| Speed | Print speeds varying from 2 to 8 inches per second | Quick production for high-demand environments |

Components of a Food Label Printer

A food label printer is essential in today's packaging industry. Its components determine its overall efficiency. Understanding these parts can help improve your labeling process.

The print head is crucial. It applies ink or thermal transfer onto labels. This component directly affects print quality. A faulty print head can cause smudges or faded prints. It’s vital to keep it clean. The control panel is another important element. It allows users to customize settings. A user-friendly interface makes adjustments easier.

Label sensors are also significant. They detect label presence and ensure proper feeding. Misaligned labels can lead to waste. Regular calibration is necessary to maintain accuracy. Additionally, the media holder should be robust. It secures label rolls during printing. A flimsy holder can cause jams, disrupting production.

How Does a Food Label Printer Work?

Food label printers are essential tools for the food industry. They help businesses create clear and compliant labels. These printers use thermal transfer technology or direct thermal printing. The choice of method depends on the desired durability and print quality. Thermal transfer printers use a heated ribbon to transfer ink onto the label material. Direct thermal printers, on the other hand, use heat-sensitive paper that turns dark when heated.

Many food businesses rely on these printers to meet regulatory requirements. According to industry reports, about 70% of food companies prioritize accurate labeling. Labels provide critical information like ingredients, allergens, and nutritional values. With consumer awareness growing, clear labeling enhances trust. Mistakes can be costly, both financially and reputationally. A poorly printed label might result in product recalls or fines.

**Tips:** Ensure your labels are easy to read. Use larger fonts and vivid colors. Regularly check printer settings for consistency. Test print labels before full production to catch errors. Remember, a small glitch can lead to major issues down the line. Stay updated on labeling regulations to avoid surprises.

Benefits of Using a Food Label Printer

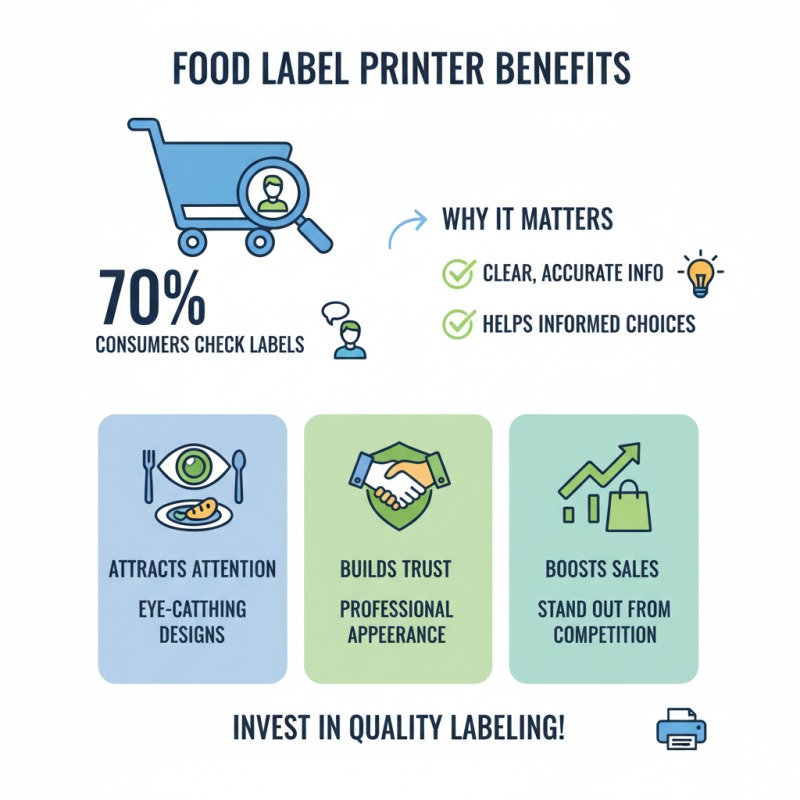

Using a food label printer offers significant benefits for businesses in the food industry. According to a recent report, around 70% of consumers check food labels before making a purchase. This illustrates the importance of clear, accurate labeling. High-quality labels can attract attention and help customers make informed choices.

Label printers enable quick and customizable printing solutions. Businesses can easily update labels with new ingredients or nutritional information. This flexibility helps companies comply with regulations more efficiently. A study found that companies using label printers saw a 35% reduction in compliance errors. However, implementing these systems isn't always seamless. Businesses may face initial setup costs and training.

The use of food label printers also promotes sustainability. Many models use eco-friendly materials. Businesses can reduce waste by printing only what they need. Still, improper usage can lead to excess labels that clutter and confuse. Finding the right balance is critical for success in this area. Overall, food label printers provide valuable tools for ensuring clarity and compliance in the food market.

Applications of Food Label Printing in the Industry

Food label printing is crucial in the food industry. It ensures products are safely consumed and properly marked. Labels provide essential information. They inform consumers about ingredients, nutritional values, and allergens. Accurate labeling is vital for customer trust. Unclear labels can lead to distrust and health risks.

Many industries use food label printing. Restaurants rely on it for meal tags. Food manufacturers need labels for packaged goods. Bakeries print labels for pastries and bread. Each label is an opportunity to market a product. Eye-catching designs can attract customers. However, mistakes in printing can have serious consequences. A tiny typo can mislead consumers.

**Tips:** Always double-check your labels before printing. Verify ingredient lists and nutritional facts. Test different label designs to see what works best. Gather feedback from consumers to improve your labeling process.

Related Posts

-

Top 10 Package Label Printer Manufacturers from China at the 137th Canton Fair

-

What Makes a Packaging Label Printer Essential for Modern Businesses

-

How to Choose the Best Logo Label Printer for Your Business Needs

-

Top 10 Best Logo Label Printers for Your Small Business in 2023

-

Unlocking the Power of Best Food Packaging Label Printers with In Depth Technical Specifications and User Guide

-

Innovative Applications of Printing Label Machines Across Diverse Industries