What is a PU Foam Lamination Machine and How Does It Work?

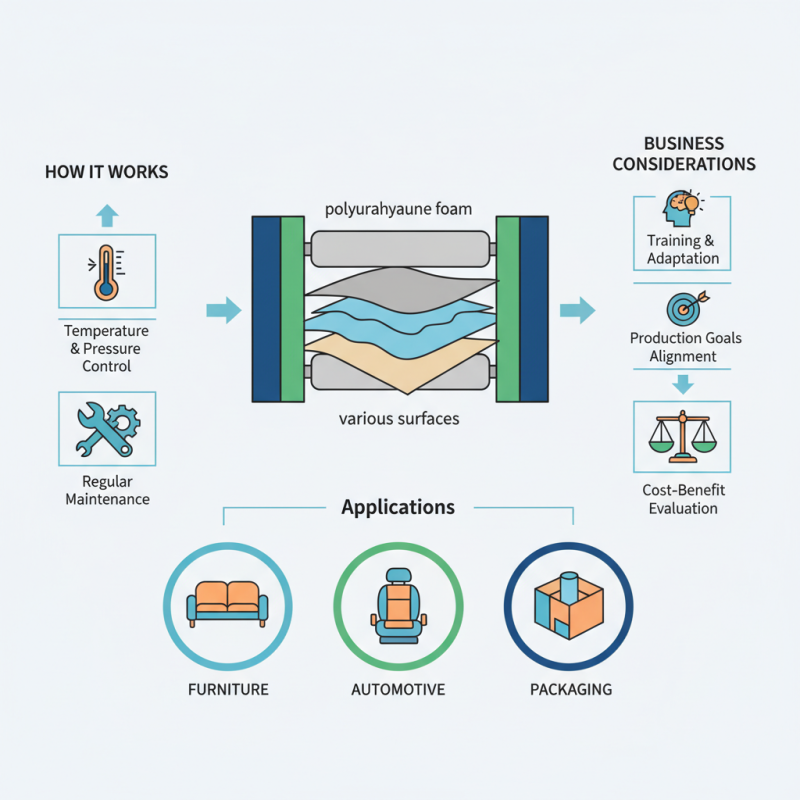

The PU foam lamination machine is a crucial tool in modern manufacturing. It revolutionizes how we bond materials. This machine integrates layers of polyurethane foam with various surfaces, enhancing insulation and comfort in products. Its applications span across furniture, automotive, and packaging sectors.

Understanding how the PU foam lamination machine operates is vital for businesses. The process involves precise temperature control and pressure application. Users often overlook the importance of maintenance. Regular checks on the machine can prevent costly downtimes. This awareness can significantly enhance production efficiency.

As we explore this technology, one might wonder if it's always the best choice. While the benefits are clear, some businesses may face initial challenges. Adapting to this equipment requires training. It's essential to evaluate if the PU foam lamination machine aligns with your production goals. Each decision holds weight in this competitive landscape.

What is PU Foam and Its Applications in Various Industries

Polyurethane (PU) foam is widely used across various industries due to its versatility and durability. It is foam formed from a polymer, making it lightweight yet strong. Reports indicate that the global PU foam market was valued at over $50 billion in 2021 and is expected to grow significantly. This growth stems from its applications in automotive, construction, and furniture industries.

In the automotive sector, PU foam is used for seats, dashboards, and insulation. It offers excellent cushioning and reduces noise, making vehicles more comfortable. The construction industry utilizes PU foam for insulation in buildings. It provides effective thermal resistance, helping to lower energy costs. Additionally, furniture manufacturers favor PU foam for upholstery, providing comfort and longevity in their products.

However, the production process of PU foam can sometimes lead to environmental concerns. The chemicals used in the manufacturing process may contribute to pollution if not managed properly. This industry must reflect on sustainable practices. Exploring bio-based PU alternatives could provide a viable solution, reducing carbon footprints while maintaining quality. The benefits of PU foam are clear, but the environmental challenges deserve attention.

PU Foam Lamination Machine Data Table

| Dimension | Value |

|---|---|

| Machine Type | Automatic |

| Max Working Width | 2000 mm |

| Layer Thickness | 10 mm to 50 mm |

| Lamination Speed | 5 m/min |

| Power Consumption | 15 kW |

| Application Industries | Furniture, Automotive, Packaging, Electronics |

| Control System | PLC |

Overview of PU Foam Lamination Machines and Their Components

PU foam lamination machines are vital in various industries. They bond polyurethane foam with other materials to create multi-layered products. This enhances durability and comfort, essential for items like mattresses and automotive interiors.

The machine consists of several key components. The feeding system is responsible for loading the foam and the laminate material. Rollers then press these layers together. Glue applications ensure a strong bond. Often, heat is used to activate these adhesives, leading to a seamless finish.

However, challenges do arise. The calibration of pressure and temperature must be precise. Too much heat, and the foam could lose its properties. Not enough adhesive, and the layers may separate over time. Such miscalculations can lead to increased waste and inefficiencies, prompting operators to rethink their methods.

Step-by-Step Process of How PU Foam Lamination Machines Operate

PU foam lamination machines are essential in various industries. They are used to bond polyurethane foam to various surfaces. The process typically consists of several key steps. First, the materials are prepared. The foam, which can be soft or rigid, is carefully cut. The surfaces that will be laminated are also pre-treated to ensure a strong bond.

Next, the operator places the foam and the substrate material into the machine. The lamination machine applies heat and pressure to fuse the layers. According to industry reports, this process can improve the adhesion strength significantly. Data shows that adhesion strength can reach up to 200 kPa in optimal conditions. However, factors like temperature and pressure must be monitored closely. It is crucial to adjust these parameters to achieve the desired results.

After lamination, the final product is inspected. Quality control measures are necessary to ensure durability and performance. Operators often face challenges such as uneven application or material defects. Continuous training on machine handling is vital to mitigate these issues. With such complexity, operators must remain vigilant. It's clear that while PU foam lamination machines provide efficient solutions, they require careful oversight and expertise.

Key Benefits of Using PU Foam Lamination Machines in Manufacturing

PU foam lamination machines play a crucial role in manufacturing processes. They bond various materials together, enhancing product durability. These machines typically utilize polyurethane foam. This foam provides excellent insulation and cushioning properties. The lamination process can improve the overall quality of a product.

One significant benefit of using these machines is increased efficiency. They reduce labor costs and speed up production. Workers can focus on more complex tasks. However, the initial investment in such machines can be high. Manufacturers must weigh costs against potential savings.

Flexibility is another key advantage. PU foam lamination machines can work with different materials. This adaptability is valuable in rapidly changing markets. Still, operators must be trained properly. Misuse can lead to waste and poor-quality output. Thus, while these machines offer numerous benefits, careful implementation is essential for success.

Market Trends and Future Developments in PU Foam Technology

PU foam technology is evolving rapidly. The market is seeing innovative developments that enhance efficiency and applications. Manufacturers are focusing on sustainable materials. Eco-friendly options are attracting attention. This trend is reshaping product design and demand.

Tips: Consider energy-efficient machines to minimize costs. Research sustainable foam options to meet market needs.

The future of PU foam suggests smart integration. Automation and IoT can optimize processes. These advancements may improve quality control. However, transitioning to new technologies poses challenges. Companies must adapt and invest in training.

Tips: Stay informed about emerging tech trends. Evaluate the cost-benefit of upgrades before investing. Balancing innovation with practicality is key.