Essential Tips for Choosing Flexible Packaging Film?

Choosing the right Flexible Packaging Film is crucial for product success. This film protects your products while enhancing their appeal. With various options available, making the right choice can be challenging.

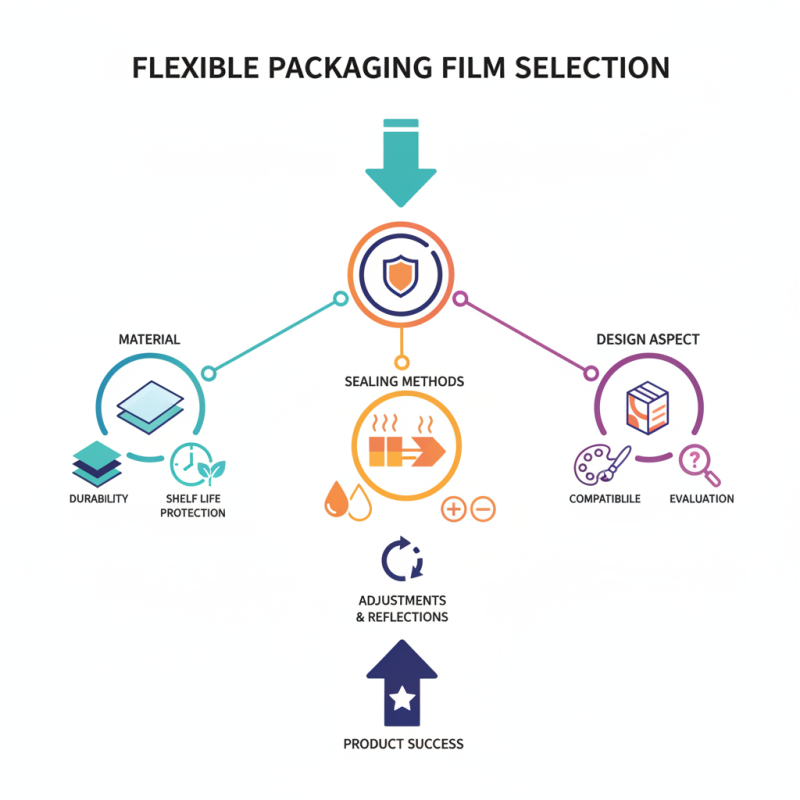

Consider the material. Some films offer better durability, while others prioritize clarity. A product’s shelf life often hinges on this decision. Think about the sealing methods too. Some films require heat sealing, while others use adhesive. Each method has its pros and cons.

Don't overlook the design aspect. The right graphics can make a huge impact. However, ensure that the design works well with your chosen film. It's important to remember that not every film is suitable for all products. Evaluate your needs carefully. Inflexibility at this stage can lead to bigger problems later. Always be ready for adjustments and reflections on your choices.

Understanding the Basics of Flexible Packaging Film Types

Flexible packaging films come in various types, each suited for different applications. Common types include polyethylene, polypropylene, and laminates. Polyethylene is lightweight and offers good moisture barrier properties. This makes it great for food packaging. Polypropylene is stiffer and more transparent, often used for bags and wraps. Laminates combine materials to enhance strengths and weaknesses uniquely.

When choosing flexible packaging film, consider the product's specific needs. Film thickness influences durability and shelf life. Too thin may lead to tears; too thick may be wasteful. The choice of barrier properties is also crucial. Products that require high moisture resistance need effective films in that regard.

Another tip is to evaluate sustainability options. Eco-friendly materials are becoming more popular. Consumers are increasingly aware of environmental impact. However, these materials may have different handling characteristics. Testing is essential to ensure they meet performance criteria. Each choice should be tested for the intended application, avoiding assumptions about their effectiveness. This way, you can create packaging that not only looks good but also performs well.

Comparison of Flexible Packaging Film Types

This chart illustrates the market share distribution among various types of flexible packaging films. The data shows that Polyethylene (PE) remains the most popular choice, followed by Polypropylene (PP) and Polyester (PET). Understanding these types can help in making informed decisions on packaging solutions.

Key Factors to Consider When Selecting Flexible Packaging Film

Choosing flexible packaging film requires careful consideration of several key factors. Material type is essential. Different materials offer various benefits, such as barrier properties and durability. Polyethylene and polypropylene are popular choices for their flexibility and cost-effectiveness. However, they may not provide the best moisture barrier. Evaluate your product's needs thoroughly. Will it be exposed to moisture or air? This is crucial.

Another factor to consider is thickness. A thicker film can offer better protection but might increase costs. A balance is often needed. It’s important to assess how much protection your product actually requires. Testing different thicknesses may help to find the right fit. Consider the environmental impact too. Eco-friendly options are increasingly available. While they can initially cost more, they resonate with eco-conscious consumers.

Finally, printing and aesthetics should not be overlooked. The look of the packaging can influence consumer perception. Make sure the film can accommodate your branding needs. It’s a delicate balance between function and design. Sometimes, compromises will be necessary. Keep revisiting your choices as the market evolves.

Evaluating Material Properties for Optimal Packaging Performance

Selecting the right flexible packaging film requires a deep understanding of material properties. An optimal film balances durability, flexibility, and barrier performance. For instance, polyethylene (PE) films are widely chosen for their moisture resistance. According to the Flexible Packaging Association, films made from PE account for about 36% of the overall flexible packaging market.

Evaluating tensile strength is key. A film with high tensile strength can withstand pressure during handling and shipping. A study from Smithers Pira indicates that films with tensile strengths above 10 MPa ensure better product protection. However, achieving the right thickness can be challenging. Too thick might reduce flexibility, while too thin can compromise durability.

Barrier properties are another critical factor. Films with high oxygen and moisture barriers are essential for preserving product freshness. Research suggests that 30% of spoilage in packaged goods is due to inadequate barrier performance. Selecting a film that meets specific barrier requirements can significantly extend shelf life. Yet, finding the perfect balance between cost and quality often leads to tough decisions for manufacturers.

Essential Tips for Choosing Flexible Packaging Film

| Material Type | Thickness (microns) | Barrier Properties | Sealing Temperature (°C) | Printability |

|---|---|---|---|---|

| Polyethylene (PE) | 30 | Good for moisture | 150-180 | Good |

| Polypropylene (PP) | 40 | Excellent gas barrier | 160-200 | Excellent |

| Polyester (PET) | 50 | Good for oxygen | 180-220 | Very Good |

| Co-extruded Films | 40-100 | Tailored properties | 150-210 | Good |

| Metallized Films | 12-50 | Superior barrier | 150-180 | Moderate |

Assessing Cost-Effectiveness in Flexible Packaging Solutions

When evaluating flexible packaging solutions, cost-effectiveness is crucial. Understanding the overall costs can save significant money. Look beyond the initial price of the film. Consider how the packaging will perform over time. Will it keep products fresh? Will it withstand environmental factors like moisture and light?

Think about the right material for your needs. Some films offer better protection but may cost more. Assess the trade-offs. Are you willing to invest more upfront for better shelf life? Alternatively, are you okay with a shorter expiration if it reduces costs? Look at your product's specific requirements before making a decision.

Measure the impact of packaging on your supply chain. Sometimes, cheaper films lead to more product loss during transportation. It's essential to evaluate the long-term consequences. An educated choice will enhance both efficiency and customer satisfaction. Balancing cost with quality often requires careful consideration of all these factors.

Sustainability Considerations in Choosing Flexible Packaging Film

Sustainability is a vital consideration in choosing flexible packaging film. A recent report by the Flexible Packaging Association indicates that flexible packaging accounts for over 20% of the total packaging market. This growth is closely tied to the increasing demand for more sustainable options. However, sustainability is not just about the final product; it encompasses the materials used, energy consumed, and waste generated during production.

Biodegradable films are gaining traction. Research suggests that these materials can significantly reduce landfill waste. They typically break down within a few months under the right conditions. Yet, challenges remain. For example, the performance of biodegradable films often lags behind conventional options. Brands must weigh these trade-offs carefully.

Another aspect is recyclability. Many flexible packages cannot be recycled through curbside programs, causing confusion among consumers. Industry studies reveal that only 9% of plastic waste is recycled. This calls for better infrastructure and consumer education. The commitment to sustainability must include improving recycling rates and developing clear labeling systems. Balancing performance, cost, and environmental impact is complex but necessary for a more sustainable future.