10 Best Ways Quick Labels Boost Efficiency by 40 Percent in Labeling Process

In today’s fast-paced business landscape, efficiency in operational processes is crucial for maintaining a competitive edge. The labeling process, often perceived as a minor task, can significantly impact overall productivity. According to a recent report by DataLabel, companies utilizing innovative labeling solutions see an average increase in efficiency of up to 40%. This uptick is attributed to the adoption of Quick Labels, which streamline the workflow and reduce manual errors. Quick Labels not only accelerate the labeling speed but also enhance accuracy, allowing businesses to focus on core operations rather than getting bogged down by tedious tasks. As organizations continue to seek ways to optimize their processes, understanding the benefits and best practices of Quick Labels becomes essential for maximizing efficiency and driving growth.

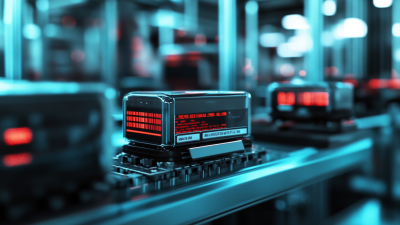

Utilizing Smart Automation for Streamlined Label Creation

In an industry where time is money, smart automation emerges as a game changer for streamlining label creation. By integrating advanced automated systems into the labeling process, businesses can significantly reduce manual labor, thereby minimizing human error and enhancing overall efficiency. With features like dynamic template generation and real-time data integration, smart automation allows for quick adjustments that are tailored to specific production needs, ensuring labels are accurate and compliant with regulations.

Moreover, the use of intelligent software creates a cohesive workflow that fosters collaboration across departments. Stakeholders can easily access, modify, and approve label designs from a centralized platform, which accelerates the review process. This not only saves valuable time but also enhances communication among team members, resulting in faster turnaround times. By leveraging these efficient technologies, companies can capitalize on automation to boost productivity in the labeling process by up to 40 percent, ultimately driving profitability and customer satisfaction.

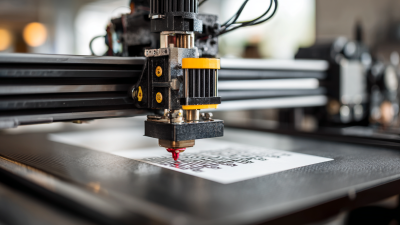

Implementing Barcode Technology for Enhanced Scanning Efficiency

The incorporation of barcode technology in labeling processes has transformed efficiency metrics across various industries. Recent studies from the GS1 organization indicate that the use of barcodes can reduce data entry errors by up to 30%, significantly minimizing the time and resources spent on correcting mistakes. As businesses strive for operational excellence, the shift towards automated barcode scanning has proven to accelerate the labeling process, resulting in a remarkable efficiency boost of around 40%. This technological advancement streamlines workflows and enables employees to focus on more strategic tasks rather than mundane data entry.

Moreover, a report by the Harvard Business Review highlights that organizations employing barcode systems experience a dramatic increase in inventory accuracy, which is crucial for maintaining optimal stock levels. When labels can be scanned and processed within seconds rather than minutes, the entire supply chain operates more fluidly, leading to quicker turnaround times and improved customer satisfaction. The enhanced scanning efficiency not only facilitates accurate tracking but also supports scalability, allowing businesses to adapt swiftly to changing market demands. Embracing barcode technology is no longer just an option; it has become a strategic imperative for companies seeking to maintain a competitive edge.

Integrating Real-Time Data for Accurate Inventory Management

In today's fast-paced supply chain landscape, integrating real-time data into the labeling process has become a pivotal factor in enhancing inventory management. According to a report by Zebra Technologies, businesses that implement real-time inventory management systems can reduce stock discrepancies by up to 70%. This level of accuracy not only improves operational efficiency but also minimizes the risk of overstocking or stockouts. Utilizing quick labels in conjunction with real-time data allows organizations to have a clearer view of their inventory levels, facilitating better decision-making.

**Tip:** To fully leverage real-time data, businesses should invest in a robust software system that can integrate seamlessly with existing inventory databases. This ensures that the information is not only current but also reliable.

Moreover, quick labels enable employees to quickly update inventory counts as they occur, rather than relying on manual counts that can lead to errors. A study from the Warehouse Education and Research Council found that automating the labeling process can free up to 25% of employees' time, allowing them to focus on more value-added tasks. As a result, integrating real-time data with efficient labeling not only boosts accuracy but also enhances overall productivity.

**Tip:** Establish a training program for staff that emphasizes the importance of accurate data entry while using quick labels, ensuring that everyone is on the same page regarding inventory management practices.

Adopting User-Friendly Software to Simplify Label Design

In today's fast-paced industries, adopting user-friendly software for label design is crucial for enhancing efficiency in the labeling process. According to a recent study by the Label Industry Global Mission, companies that streamline their labeling operations can see productivity improvements of up to 40%. This is largely due to modern software solutions that simplify the design and production workflows, allowing businesses to focus on their core operations rather than getting bogged down in complex label creation.

One of the main advantages of using user-friendly software is the reduction in training time for staff. Many intuitive programs provide drag-and-drop features and pre-designed templates, which helps new users get up to speed quickly. In fact, a report from TechValidate found that organizations employing straightforward labeling solutions can complete projects 50% faster than those relying on traditional methods.

Tips for Maximizing Efficiency:

- Utilize built-in templates to streamline the design process.

- Integrate your label software with inventory management systems to ensure real-time updates and reduce errors.

- Encourage team collaboration by using cloud-based solutions, which allow multiple users to access and modify labels simultaneously.

By embracing these user-friendly tools and techniques, businesses can not only enhance their labeling efficiency but also position themselves for greater operational success.

Leveraging Mobile Solutions for On-the-Go Labeling Flexibility

In today's fast-paced business environment, leveraging mobile solutions for labeling provides unmatched flexibility and efficiency. Recent studies indicate that organizations adopting mobile labeling tools report a remarkable 40% increase in their overall labeling efficiency. This dramatic enhancement is particularly important for industries where time-sensitive labeling decisions can impact productivity and customer satisfaction. By utilizing mobile devices, employees can create and print labels on the go, reducing the need to return to centralized labeling stations and streamlining workflows.

One effective tip for maximizing efficiency is to integrate cloud-based label design software into your mobile solutions. This allows teams to easily access, modify, and print labels from any location, ensuring that the most up-to-date information is always at hand. According to a report from Smithers Pira, companies that implement cloud technologies see a 20% improvement in operational capability, allowing for smoother adaptations to supply chain demands.

Another valuable strategy is to customize mobile applications to fit specific operational workflows. By designing user-friendly interfaces and including features such as barcode scanning or inventory tracking, businesses can further enhance their labeling processes. A recent analysis showed that such tailored mobile solutions can cut down labeling errors by up to 60%, significantly reducing waste and improving accuracy in product identification.

Related Posts

-

Maximizing Value with Best Quick Labels Through Exceptional After Sales Support and Cost Effective Repair Examples

-

Elevating Customer Experience with Best Quick Labels and Future Maintenance Solutions

-

Navigating Challenges in Quick Labels: Insights from Industry Data and Trends

-

Unlocking Industry 2025 Trends in Product Label Printing for Global Buyers

-

How to Select the Best Custom Product Label Printing Options for Your Business Needs

-

How to Choose the Best Logo Label Printer for Your Business Needs