Essential Tips for Choosing the Best Label Printer for Food Packaging

In the rapidly evolving food packaging industry, the significance of choosing the right Label Printer for Food Packaging cannot be overstated. According to a recent report by Smithers Pira, the global market for food packaging labels is projected to reach $60 billion by 2025, driven by consumer demand for clarity and transparency in food labeling. As food safety regulations become more stringent and consumers increasingly lean towards products with informative labeling, the role of an efficient label printer grows paramount.

Expert in food packaging technology, Dr. John Anderson, emphasizes this sentiment, stating, "A quality Label Printer for Food Packaging not only enhances brand presentation but also ensures compliance with industry standards, making it a pivotal investment for manufacturers." The ability to produce accurate, durable, and visually appealing labels plays a crucial role in attracting consumers and providing vital product information, from ingredients to expiration dates. Considering the array of options available in the market today, selecting the appropriate label printer that meets both operational needs and regulatory requirements is essential for any business in the food sector.

Key Considerations for Selecting a Label Printer for Food Packaging

When selecting a label printer for food packaging, several key considerations should guide your decision-making process. First and foremost, it is crucial to evaluate the printer's printing technology. Thermal transfer and direct thermal printing are the most common options. Thermal transfer offers durability, making it ideal for food products that may be exposed to moisture or varying temperatures. On the other hand, direct thermal is often more cost-effective and simpler to operate but may not withstand such harsh conditions. Understanding the specific needs of your products will inform which technology will work best for your packaging requirements.

Another important aspect to consider is the printer's speed and volume capabilities. High-demand food items may require a printer that can keep up with fast production rates while maintaining quality. This means looking for a model that offers high-resolution printing and quick label production times. Additionally, compatibility with different label materials is essential. Food packaging often requires adhesive labels that can adhere to a variety of surfaces, including plastic, glass, and paper. Therefore, ensure the printer can handle various materials while providing clear, smudge-resistant prints that withstand the rigors of transportation and storage.

Types of Label Printers Suitable for Food Applications

When selecting a label printer for food applications, it is essential to understand the types available and their suitability for specific packaging needs. There are three primary types of label printers: thermal transfer, direct thermal, and inkjet printers.

Thermal transfer printers utilize a ribbon that melts ink onto the label material, providing durability and resistance to moisture and temperature, making them an excellent choice for products with varying storage conditions. These printers are ideal for sticky and adhesive labels often necessary in food packaging.

Direct thermal printers, on the other hand, create images directly on heat-sensitive labels without the need for ink or ribbons. While they are convenient and cost-effective for short-term labeling, their durability may be compromised when exposed to heat or moisture. Thus, they are best suited for labels that will be used immediately and not stored long-term, such as sale labels or shipping information.

Inkjets, while less common in food labeling, can produce vibrant colors and detailed images, making them attractive for custom labels and branding, particularly in artisanal or gourmet food packaging.

When choosing the right label printer, consider the product type, storage conditions, and the desired label longevity. Each printer type has its advantages, and the best choice will align with the specific requirements of your food packaging applications.

Essential Features for Food Packaging Label Printers

When selecting a label printer specifically for food packaging, it’s vital to consider several essential features that ensure compliance and high-quality output. First and foremost, the printer should support a variety of label materials, such as waterproof, oil-resistant, and tear-proof options. This versatility is crucial as it allows the labels to withstand various conditions, including refrigeration and exposure to moisture, which are common in food storage and display environments.

Another important feature is the ability to print in high resolution, as clear and professional-looking labels can significantly enhance product appeal. This includes not just text but also graphics, barcodes, and nutritional information that need to be readable and attractive. Additionally, consider printers that offer easy integration with design software for customizing labels. User-friendly interfaces and connectivity options, such as USB or wireless capabilities, are also critical for efficient operation, allowing for seamless updates and quick label printing when needed.

Evaluating Print Quality and Speed for Food Labels

When selecting a label printer for food packaging, print quality and speed are critical factors that can significantly impact your branding and operational efficiency. High-resolution printing is essential for creating vibrant, readable labels that not only meet regulatory requirements but also catch the customer’s eye. A printer that delivers crisp text and vivid colors will enhance the overall presentation of your product, making it stand out on the shelves. Opt for a model that supports various label sizes and materials, as this flexibility can accommodate different types of food packaging.

In addition to print quality, speed is another vital aspect to consider. A fast label printer can streamline your production process, allowing you to keep up with demand without compromising on quality. Look for printers that offer high-speed printing capabilities to avoid bottlenecks in your packaging line.

**Tip 1:** Before making a purchase, conduct some tests by printing sample labels. This will help you gauge both the quality and the speed of the printer you are considering.

**Tip 2:** Investigate the printer’s maintenance requirements as well. A model that is easy to clean and maintain will save you time and effort in the long run, ensuring that you can produce high-quality labels consistently.

**Tip 3:** Lastly, compatibility with different label materials is crucial. Ensure the printer can handle materials such as waterproof, oil-resistant, or thermal labels to suit various food products, ensuring durability and adherence to industry standards.

Print Quality and Speed Evaluation of Label Printers for Food Packaging

Cost-Effectiveness and Budgeting for Food Label Printing

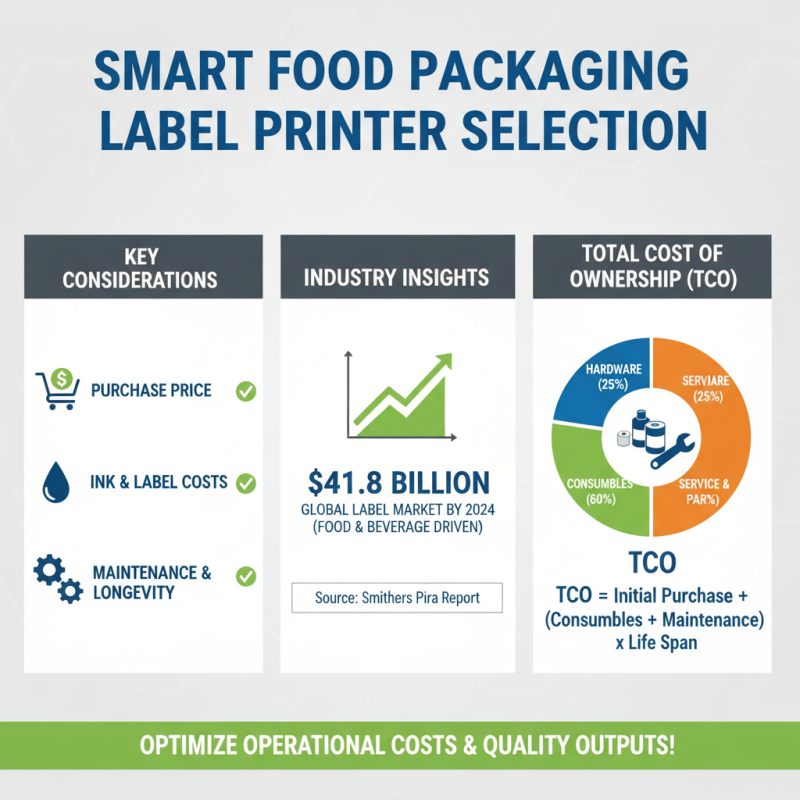

When selecting a label printer for food packaging, cost-effectiveness is a critical factor that businesses must consider. According to a recent industry report by Smithers Pira, the global label market is projected to reach $41.8 billion by 2024, driven largely by the food and beverage sector. This growing demand emphasizes the importance of sourcing a label printer that optimizes operational costs while providing high-quality outputs. Companies should look for printers that balance purchase price with running costs, which include labels, ink, and maintenance. Analyzing the total cost of ownership (TCO) can help businesses better understand long-term expenses associated with different printer models.

Budgeting for food label printing is equally essential, especially in a competitive market. Research indicates that businesses can save up to 30% on labeling costs by selecting the right technology and working with cost-efficient materials. For example, adopting digital printing solutions can significantly reduce waste and allow for shorter production runs, which is particularly advantageous for small to medium-sized enterprises that may have limited labeling needs. Additionally, investing in software that integrates with inventory management systems can streamline operations and minimize the costs associated with label design and production, ensuring that budgets remain intact while meeting industry regulations.

Related Posts

-

Effective Solutions for Food Packaging Label Printer Integration in Your Production Line

-

Maximize Your Business Potential at the 137th Canton Fair with Our Innovative Packaging Label Printer

-

Understanding Industry Production Standards and Challenges in Best Printing Labels

-

5 Essential Features of the Best Food Packaging Label Printers for Global Buyers

-

Uncovering the Impact of Best Digital Label Press in Food and Beverage Packaging Solutions

-

Unleashing the Power of Chinese Manufacturing to Elevate Your Brand with the Best Logo Label Printer