Unlocking the Future of Packaging with Digital Label Printing Innovations

In recent years, the packaging industry has witnessed a profound transformation driven by advancements in Digital Label Printing. According to a report by Smithers Pira, the global digital label market is expected to reach $26.5 billion by 2024, growing at a CAGR of 11% from 2019. This growth is largely attributed to the increasing demand for customized packaging solutions and shorter production runs, which traditional printing methods struggle to accommodate. Digital Label Printing not only enhances operational efficiency but also allows brands to respond swiftly to market trends and consumer preferences. With the integration of technologies like variable data printing and sustainable materials, businesses can achieve greater personalization and reduced environmental impact. As companies continue to explore these innovations, the future of packaging seems poised for exciting developments that leverage Digital Label Printing to meet evolving consumer expectations and sustainability goals.

Exploring the Advantages of Digital Label Printing in Modern Packaging

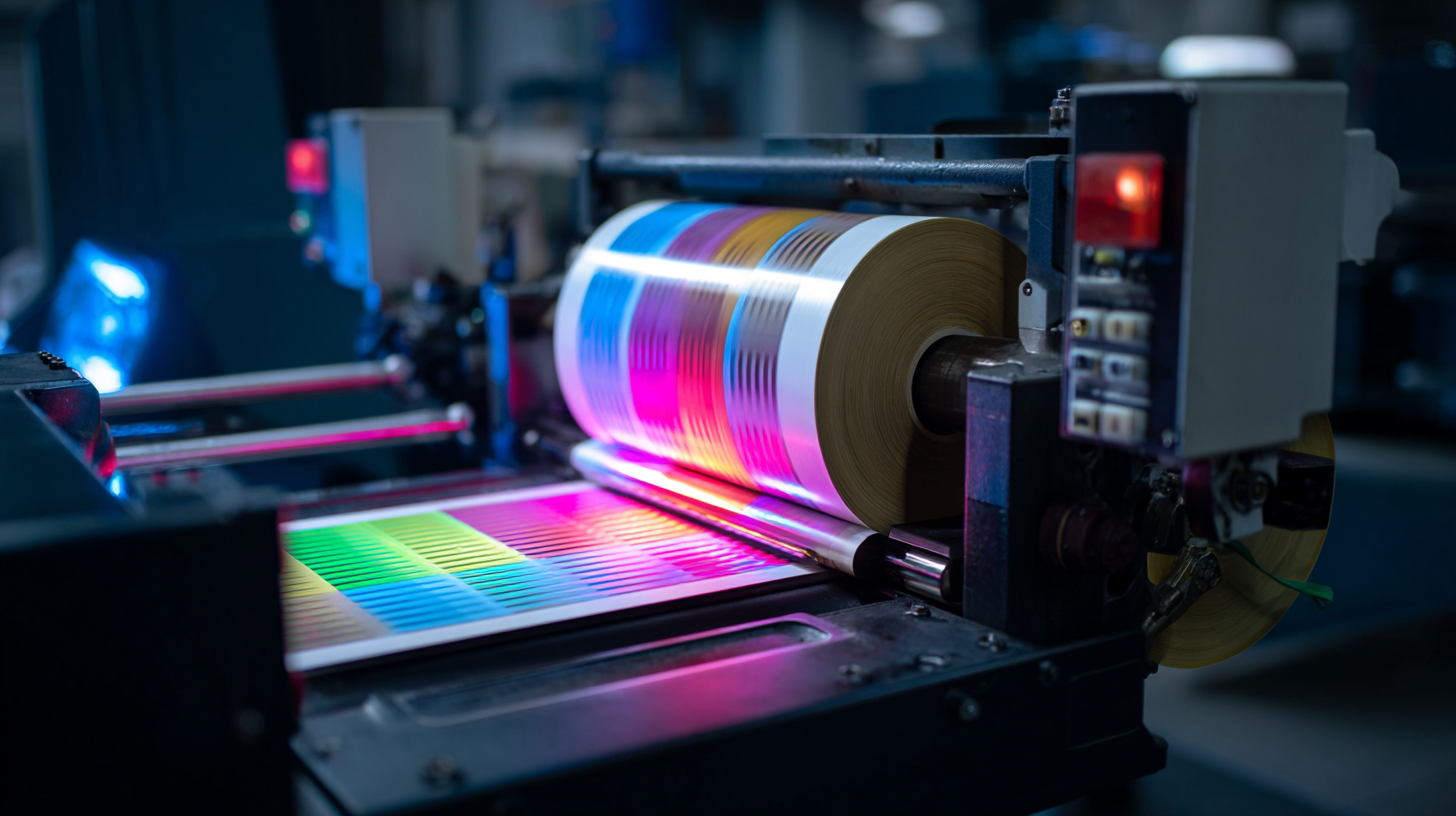

Digital label printing is transforming the packaging landscape, offering numerous advantages that cater to the demands of modern industries. As manufacturers and logistics providers face increasing pressure for traceability and transparency, industrial labels play a crucial role in conveying essential information such as product details, safety instructions, tracking data, and regulatory compliance. The shift towards digital printing technology not only enhances flexibility but also allows for quicker turnaround times, thus meeting market demands more efficiently.

Tips for leveraging digital label printing include opting for variable data printing, which enables personalized labeling and targeted marketing efforts. Additionally, exploring eco-friendly printing materials can align your brand with sustainability initiatives, appealing to conscious consumers. As the market for digital printers is projected to grow significantly through 2025 to 2033, companies that invest in these innovations will be poised to enhance operational excellence while staying ahead of industry trends and consumer expectations.

Key Technologies Driving Innovation in Digital Label Printing

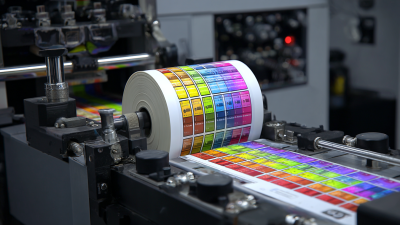

The label printing industry is undergoing a transformative phase, driven by key technologies that foster digital innovation. As highlighted at the recent open house events, major players in the field are showcasing their latest advancements in digital printing solutions. The market size for labels was valued at approximately USD 52.3 billion in 2025 and is anticipated to grow to USD 89.7 billion by 2035, reflecting a compound annual growth rate (CAGR) of 5.5%. This growth is a testament to the integration of cutting-edge digital processes in label and packaging printing.

Tips:

- Embrace automation in your printing processes to streamline production and reduce lead times.

- Explore the options for customizable digital labels to cater to diverse market needs and enhance customer engagement.

- Stay updated with industry trends and innovations by participating in trade shows and workshops to discover emerging solutions that can benefit your operations.

Implementing Sustainable Practices through Digital Label Printing Solutions

Digital label printing is at the forefront of a transformative wave in the packaging industry, particularly when it comes to sustainability. By utilizing advanced digital printing technologies, businesses can minimize waste and reduce their carbon footprint, all while maintaining high-quality output. This transition not only conserves materials but also allows for on-demand printing, meaning companies can produce labels only as needed, significantly cutting down on excess inventory and resources.

**Tip:** To enhance sustainability in your packaging, consider integrating eco-friendly inks and recyclable materials into your label designs. This not only appeals to environmentally conscious consumers but also complies with increasing regulations around sustainable packaging.

Another advantage of digital label printing is its ability to accommodate shorter runs and customizable designs. This flexibility encourages brands to adopt more sustainable practices by enabling them to quickly adapt to market demands and consumer preferences, without overproducing. Moreover, companies can experiment with innovative designs that reflect their commitment to sustainability, thereby creating a stronger connection with their audience.

**Tip:** Explore partnering with local digital printing firms that prioritize sustainable practices, which not only supports the community but also reduces transportation emissions—an often-overlooked aspect of sustainability in packaging.

Digital Label Printing Innovations: Trends in Sustainability and Efficiency

Designing Customizable Packaging: The Role of Digital Label Printing

Digital label printing is revolutionizing the packaging industry by offering a high degree of customization that meets the unique demands of brands today. Unlike traditional printing methods, digital label printing allows for rapid changes in design and production, enabling businesses to create tailored packaging solutions on short notice. This flexibility empowers brands to respond to market trends swiftly, launch limited edition products, and engage customers with personalized packaging that enhances their brand story.

Moreover, digital label printing facilitates intricate designs and vibrant colors, which attract consumers’ attention and promote brand identity. With the ability to print smaller batches economically, companies can explore innovative designs without incurring excessive costs. This trend not only encourages creativity in packaging but also keeps product lines fresh, appealing, and relevant. Customizable packaging, powered by digital printing technology, thus plays a crucial role in brand differentiation and customer loyalty, paving the way for a more dynamic and customer-focused marketplace.

Future Trends in Digital Label Printing for Packaging Industries

The digital label printing market is poised for substantial growth, projected to expand from $39.63 billion in 2023 to approximately $87.21 billion by 2030, with a remarkable compound annual growth rate (CAGR) of 11.9% in North America. This growth is largely driven by the global shift towards digital transformation, allowing packaging industries to enhance efficiency and customization. The rising demand for sustainable and innovative packaging solutions further compels manufacturers to adopt digital printing technologies that offer quick turnaround times and reduced waste.

In addition, the global digital inkjet printing market is experiencing a significant upswing, with estimates suggesting a market size of around $140.73 billion by 2024. By 2032, the digital printing packaging market is anticipated to increase from $36.02 billion in 2025 to about $56.62 billion, representing a CAGR of 6.67%. As industries across sectors such as food, beverage, pharmaceuticals, and cosmetics seek to differentiate their products on crowded shelves, digital label printing emerges as a crucial strategy for enhancing brand visibility and customer engagement, thereby reshaping the future of packaging.

Related Posts

-

Maximize Your Business Potential at the 137th Canton Fair with Our Innovative Packaging Label Printer

-

Understanding Industry Production Standards and Challenges in Best Printing Labels

-

Uncovering the Impact of Best Digital Label Press in Food and Beverage Packaging Solutions

-

Excellence in Digital Label Printing Crafted in China for Global Impact

-

What are the Key Features of Label Printer Labels and Their Impact on Efficiency

-

Unleashing Growth Opportunities for Packaging Printers at the Record Breaking Canton Fair 2025