Effective order management and process transparency are essential for success in today’s fast-paced manufacturing industry. Ben and Neil’s new venture, PASS, offers a cloud-based ERP to help manufacturers streamline their operations, enhance communication, and modernize their workflows. For anyone new to the term, ERP stands for Enterprise Resource Planning – a software system that can automate, manage, and oversee essential operational procedures for optimal performance.

Manufacturing has always been an intricate web of processes, each stage contributing to the final product. In such an environment, efficient order management, real-time visibility, and streamlined communication are pivotal to balanced success. Many manufacturers have long relied on manual systems like Excel spreadsheets to manage their operations. After recognizing the shortcomings of existing solutions, PASS, Palmetto Advanced Software Systems, was created to fill a crucial niche in the market. Ben and Neil’s extensive 25 years of experience in manufacturing places them in the best position to address these identified issues. Their investment of time and energy in PASS is a testament to their unwavering commitment to filling in the gaps.

PASS originated from a simple yet powerful realization. While evaluating off-the-shelf options for manufacturers, Ben and Neil discovered that none of the existing offerings met their specific needs. Instead of settling for this one-size-fits-all solution, they decided to develop software tailored to their requirements that tackled the same problems that kept coming up time and time again. This experience led to the birth of PASS and a shift to prioritizing transparency, communication, and efficiency in everyday processes.

At its core, PASS is committed to simplifying manufacturing operations for small businesses and offering a cost-effective alternative to complex, expensive products designed to fit the masses. PASS addresses the unique challenges faced by manufacturers, such as:

At its core, PASS is committed to simplifying manufacturing operations for small businesses and offering a cost-effective alternative to complex, expensive products designed to fit the masses. PASS addresses the unique challenges faced by manufacturers, such as:

Order Flow Consolidation: Baked into the main dashboard is a centralized view that consolidates the entire order flow. Every stakeholder in the manufacturing process can access real-time information about the status and stage of each work order. This level of transparency fosters better decision-making and ensures everyone is on the same page.

Modernized Workflow: Moving away from cumbersome Excel sheets, PASS provides an updated system that streamlines manufacturing processes without completely overhauling existing company structures. This shift improves efficiency and reduces the risk of errors often associated with manual data entry.

Communication Enhancement: Effective communication is the cornerstone of any successful manufacturing operation. PASS promotes seamless communication among team members, suppliers, and customers. Stakeholders can easily collaborate, share information, and stay updated on the progress of orders.

By first understanding the importance of scalability and accessibility in modern manufacturing, Ben and Neil felt confident entering the market by bringing their business idea to life. PASS enables manufacturers to hone in on the power of combining an ERP with the flexibility and convenience of cloud technology. Whether in the office or on the factory floor, PASS ensures that your data is secure, easily accessible, and always up-to-date

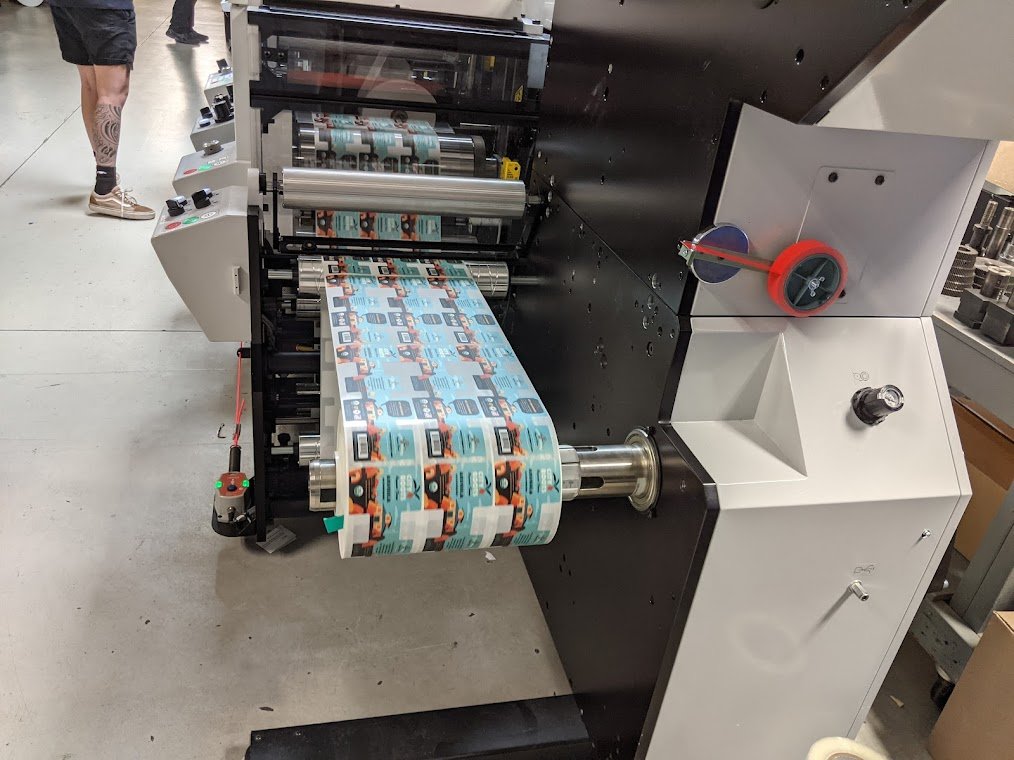

PASS was designed with manufacturers that have multiple steps in their processes in mind. So whether you’re a small manufacturer in printing operations or additive manufacturing, PASS can tighten up any processes and fit into your existing technology. In today’s competitive landscape, businesses need an affordable, specialized solution that caters to their unique specifications. PASS understands that need deeply and is working to fulfill it on a new level.

Palmetto Advanced Software Systems is more than just a software company; it is a partner in your manufacturing journey. Ben and Neil’s mission is to empower manufacturers, regardless of their size or industry, with the tools they need to thrive in an increasingly complex world. By keeping transparency and workflow efficiency as the focal point, PASS revolutionizes manufacturing processes, allowing businesses to make the most efficient use of their resources and stay competitive in evolving markets.

Join us in embracing a new era of manufacturing excellence with PASS.

One major factor that has affected the beer industry is the shortage of glass. Coming out of the pandemic, supply chain issues have resulted in many beer brands opting to purchase unprinted cans and add their own labels as needed. This not only offers more flexibility in terms of branding and design, but it also allows breweries to save money by only ordering the exact amount of cans they need at any given time.

One major factor that has affected the beer industry is the shortage of glass. Coming out of the pandemic, supply chain issues have resulted in many beer brands opting to purchase unprinted cans and add their own labels as needed. This not only offers more flexibility in terms of branding and design, but it also allows breweries to save money by only ordering the exact amount of cans they need at any given time.

As the majority of our society has pivoted digitally to obtain their daily news sources, the number of front pages available for advertising labels has steadily declined. CP&P has adapted to this downturn in demand for advertising labels by pivoting to the food, beverage, and other key markets. They have also leveraged the power of their hybrid press, added in 2022, which has opened up their capacity in plate making.

As the majority of our society has pivoted digitally to obtain their daily news sources, the number of front pages available for advertising labels has steadily declined. CP&P has adapted to this downturn in demand for advertising labels by pivoting to the food, beverage, and other key markets. They have also leveraged the power of their hybrid press, added in 2022, which has opened up their capacity in plate making.

The executive team at CP&P also engages with an independent auditor to ensure the standards are met during the interim of the 3-year ISO 9001 recertifications. These yearly audits are smaller and take about a day.

The executive team at CP&P also engages with an independent auditor to ensure the standards are met during the interim of the 3-year ISO 9001 recertifications. These yearly audits are smaller and take about a day.

John Bailey decided to reach out to CP&P about an opportunity with Ben and Neil. They assigned and presented him with two different tasks to take place over a month during his interim period–

John Bailey decided to reach out to CP&P about an opportunity with Ben and Neil. They assigned and presented him with two different tasks to take place over a month during his interim period– Because of the numbers that JB collected while on the production line, Ben and Neil can now integrate real-time data into their pricing models. This specificity of his data has provided better insights to pull from when determining current and future business and financial endeavors. The Century Management team is currently integrating this real-world data into their pricing models to ensure their costs are accurate and they can offer customers competitive pricing.

Because of the numbers that JB collected while on the production line, Ben and Neil can now integrate real-time data into their pricing models. This specificity of his data has provided better insights to pull from when determining current and future business and financial endeavors. The Century Management team is currently integrating this real-world data into their pricing models to ensure their costs are accurate and they can offer customers competitive pricing.