Century Printing and Packaging takes pride in showcasing its team of accomplished professionals, each contributing diverse expertise to the company. This month, Ben and Neil are delighted to introduce Page, an esteemed member of CP&P’s prepress team for over a year. Her transition from mechanics to graphic design has dramatically enhanced Page’s contributions to the team, making her journey worth sharing and diving deeper into.

Page’s path into the printing industry is unique, marked by her adaptability and determination to succeed no matter her role. She began her career in mechanics, working for an oil change company where she learned the ins and outs of mechanical work. “I started getting into cars a few years ago,” Page explains. “It taught me everything I know from the ground up, mechanically speaking.” As impressive as her mechanical skills are, Page’s true passion lies in graphic design.

Page’s path into the printing industry is unique, marked by her adaptability and determination to succeed no matter her role. She began her career in mechanics, working for an oil change company where she learned the ins and outs of mechanical work. “I started getting into cars a few years ago,” Page explains. “It taught me everything I know from the ground up, mechanically speaking.” As impressive as her mechanical skills are, Page’s true passion lies in graphic design.

So, she began to look for job opportunities that could marry both her passions and skills together. In her pursuit of transitioning to Graphic Design, Page accepted an opportunity at a different printing company, where she dedicated a year to refining her production skills. This experience provided the groundwork for her current position at Century Printing and Packaging.

As a member of the prepress team at CP&P, Page’s day-to-day responsibilities are both creative and technical. She spends most of her day getting customer artwork, editing, and creating labels and designs from scratch. With a foundation in graphic design and fine arts from Greenville Tech, Page has cultivated her skills independently by creating art for enjoyment. This blend of formal education and self-directed learning has empowered her with the knowledge and creativity required to thrive at CP&P.

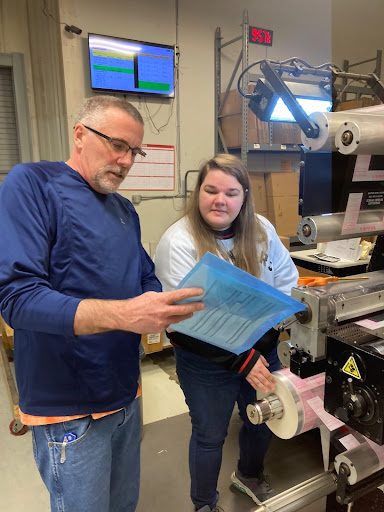

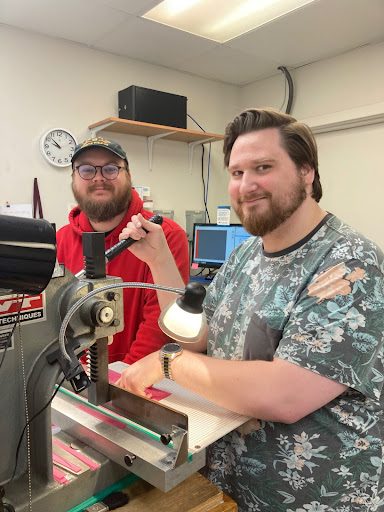

Page’s role is integral in the production of flexographic plates. As part of the Prepress team, she is responsible for creating and preparing the plates for production. Leveraging her background in mechanical engineering, Page possesses a deep understanding of the printing process. “It provides me with a comprehensive perspective on the functioning of every aspect,” she emphasizes, underscoring the value of diversified skill sets.

Since joining CP&P, Page has been able to come to work every day, knowing that what she does is aligned with her dream goals and career aspirations. “If someone asks me if this is my dream job, I would say yes,” she says enthusiastically. “I get to do a lot of work in Illustrator and Photoshop, which is exactly what I want to do.” Her passion for graphic design is evident in the results of her work.

Since joining CP&P, Page has been able to come to work every day, knowing that what she does is aligned with her dream goals and career aspirations. “If someone asks me if this is my dream job, I would say yes,” she says enthusiastically. “I get to do a lot of work in Illustrator and Photoshop, which is exactly what I want to do.” Her passion for graphic design is evident in the results of her work.

Page has had the opportunity to participate in valuable training experiences, both in-house and out-of-state. One notable experience was her week-long training in St. Louis, Missouri. “I learned how to optimize my prepress skills and tweak different things for the press,” she recalls. “It was great to meet other people in the industry and see how things are done.”

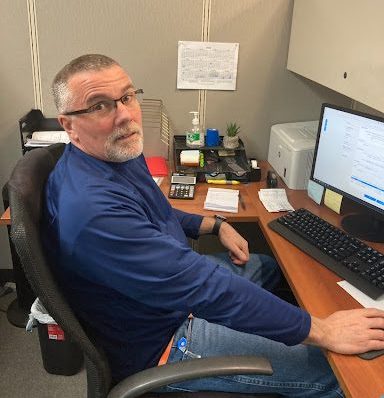

Ben, Neil, and Connie’s mentorship has been invaluable to Page’s professional development. According to Page, their guidance has helped her gain valuable problem-solving skills. Connie, who is Page’s boss, has been particularly influential due to her extensive experience in the printing industry. Page has made significant progress in her personal development, focusing on honing multitasking and time management skills that have contributed to her impressive success.

One of the most rewarding aspects of Page’s job is the positive work environment at Century Printing and Packaging. “I’ve had quite a few jobs, but this is the only one where I truly enjoy the people I work with,” she shares. “It’s like a big family.”

Page’s story exemplifies the supportive culture Ben and Neil strive to maintain at Century Printing and Packaging—a healthy workplace where every employee feels valued and motivated to excel. From fostering positivity on the production floor to encouraging open communication and collaboration between teams, CP&P sees the value in investing in its employees and the culture they are a part of from the ground up.

Page’s story exemplifies the supportive culture Ben and Neil strive to maintain at Century Printing and Packaging—a healthy workplace where every employee feels valued and motivated to excel. From fostering positivity on the production floor to encouraging open communication and collaboration between teams, CP&P sees the value in investing in its employees and the culture they are a part of from the ground up.

In today’s competitive business environment, investing in employees’ professional development is more crucial than ever. A recent study by LinkedIn found that 94% of employees would stay at a company longer if it invested in their careers. Ben and Neil recognize this and offer various training programs and opportunities for skill enhancement. This investment in staff development not only equips employees with the latest industry knowledge but also ensures they feel valued and motivated to bring their best selves to work every day.

By nurturing talent from within and prioritizing employee professional growth, Century Printing and Packaging ensures that it remains a top choice for current and prospective team members, leading to high client satisfaction and long-lasting relationships. Thank you, Page, for all that you do for our customers!

Tell us about yourself

Tell us about yourself How are the relationships with vendors in ordering materials?

How are the relationships with vendors in ordering materials? How do you deal with these challenges?

How do you deal with these challenges?

Describe your role at Century Printing and Packaging

Describe your role at Century Printing and Packaging Jacob, what’s the best part of your job?

Jacob, what’s the best part of your job? What do you like to do when you are away from work during your downtime?

What do you like to do when you are away from work during your downtime?

Mike, tell us about your background?

Mike, tell us about your background? How is the work?

How is the work? Mike, what do you enjoy about working at Century Printing and Packaging?

Mike, what do you enjoy about working at Century Printing and Packaging?

So Madison, tell us about yourself?

So Madison, tell us about yourself? What do you like about your job?

What do you like about your job? What’s a typical day like for you?

What’s a typical day like for you? Tell us what you like to do in your free time?

Tell us what you like to do in your free time?