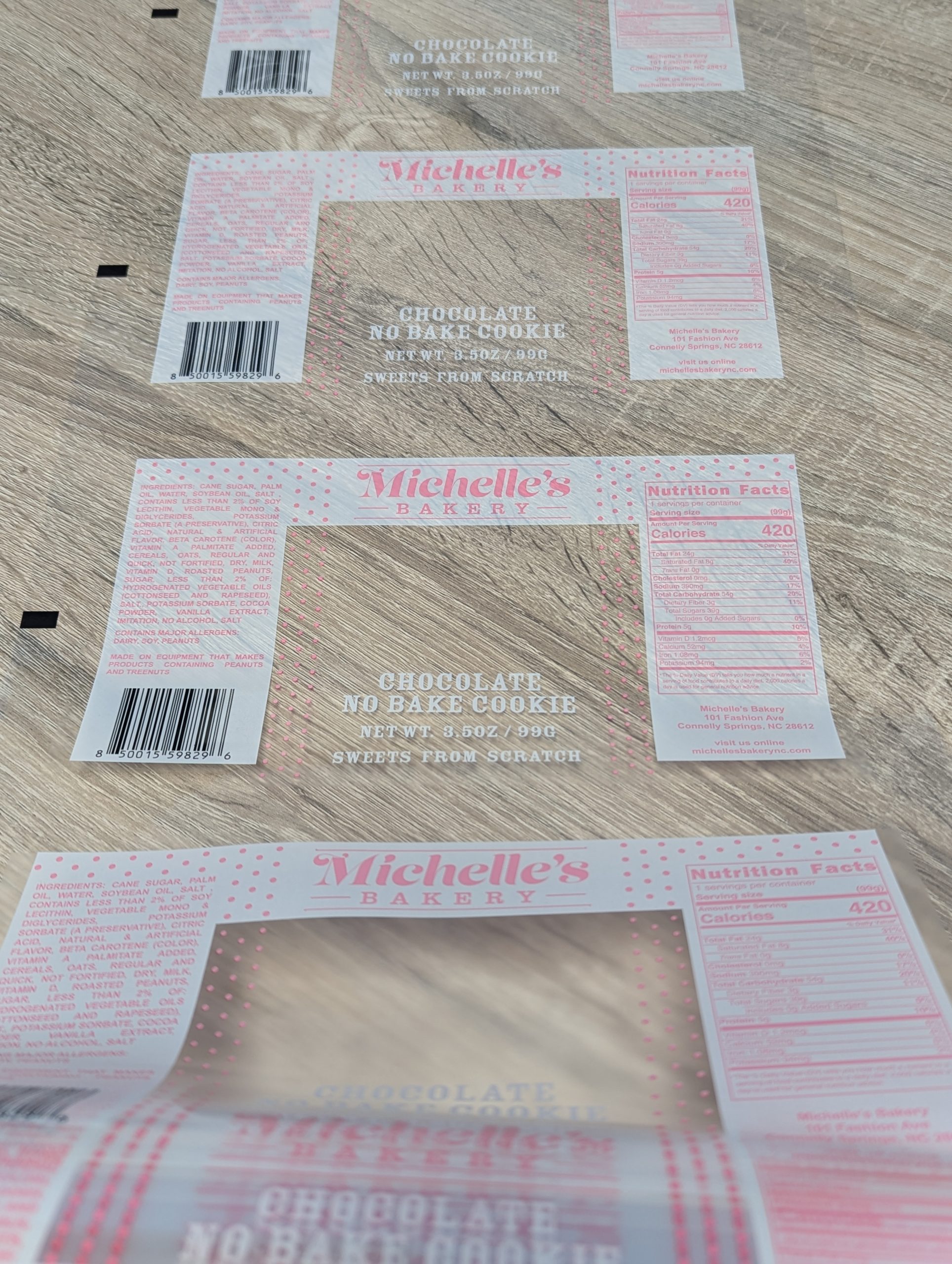

As attention spans for consumers get shorter and the push for environmental friendliness grows, product labels are expected to check many boxes. An increasing preference for a “no packaging” aesthetic has undoubtedly introduced a significant playing field for clear labels. These transparent labels effectively highlight products without occupying excessive packaging real estate, creating a more simplistic yet distinct display on shelves. However, producing these high-quality clear labels comes with challenges. For 27 years, the Century Printing and Packaging team has perfected the art of clear labeling, tackling these technical obstacles head-on. Their aptitude for finding solutions has armed them with the knowledge and techniques required to produce clear labels as an uptick in demand continues.

Clear labels can be used in various ways depending on what brands are looking to achieve. For example, brands aiming to reduce their environmental impact might want to consider a clear label over a more traditional label with a white background to showcase a cleaner, more sustainable appearance. Clear labels can also be a strategic choice when enhancing product visibility and standing out on shelves to consumers. These labels vary in clarity, ranging from slightly translucent to almost invisible, offering versatility depending on the product and packaging.

Despite the seemingly simple look, more goes on beneath the surface to achieve this sleek, modern appearance that resonates with today’s consumers.

The very nature of clear materials means that any coating or laminate must be carefully chosen and applied to avoid cloudiness or opacity. Century Printing and Packaging understands that even the slightest misstep can diminish the label’s clarity, compromising the “no packaging” look many clients seek. To achieve this, CP&P employs advanced techniques to ensure that protective layers enhance, rather than detract from, the label’s transparency.

Maintaining clarity in clear labels is crucial, but it goes beyond ensuring the material remains transparent. It also involves the label being applied correctly for the end user and firmly adhering to the packaging, considering factors such as the surface tension of the packaging material, the type of adhesive used, and the conditions under which the label will be applied. The label needs to not only look good but also perform well by adhering securely to various surfaces without peeling or bubbling. This balance between visual appeal and functional reliability is an aspect that CP&P strives to strike just right.

Maintaining clarity in clear labels is crucial, but it goes beyond ensuring the material remains transparent. It also involves the label being applied correctly for the end user and firmly adhering to the packaging, considering factors such as the surface tension of the packaging material, the type of adhesive used, and the conditions under which the label will be applied. The label needs to not only look good but also perform well by adhering securely to various surfaces without peeling or bubbling. This balance between visual appeal and functional reliability is an aspect that CP&P strives to strike just right.

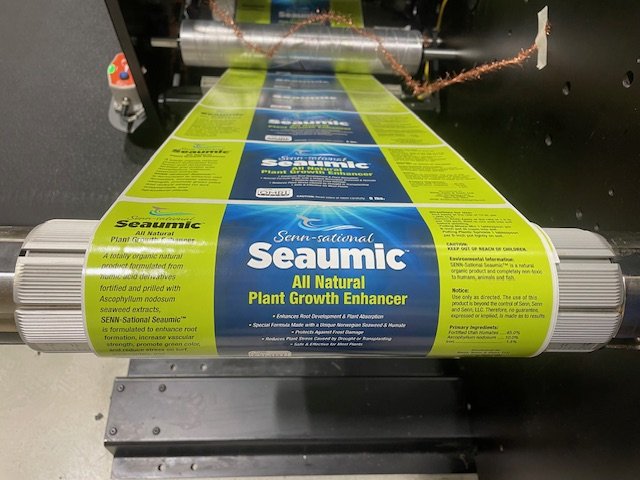

When it comes to successfully printing complex, colorful designs onto a clear label, behind-the-scenes skillfulness will prevent many problems from arising. Without a white background, colors can appear washed out, lacking the vibrancy crucial for an eye-catching label. To address this, a white ink underlay is applied, providing a bright base that allows the colors to pop. This technique requires precision in design and execution to ensure that the white ink is applied only to the necessary parts of the label without overpowering the design. In some cases, double hits of white can be used to achieve the desired opacity and color intensity.

Another technique CP&P utilizes is reverse printing, where the design is printed on the underside of the label. This method protects the printed image while allowing it to be viewed through the clear material, offering a unique and durable labeling option.

Another technique CP&P utilizes is reverse printing, where the design is printed on the underside of the label. This method protects the printed image while allowing it to be viewed through the clear material, offering a unique and durable labeling option.

Producing a clear label doesn’t end after it’s printed. Unless the post-printing stage of the label-making process is planned ahead of time, there is no guarantee that the application process will be easy and stress-free. Automatic label applicators, which rely on sensors to detect the edges of labels, can struggle with clear materials. The transparency of the label can cause the applicator to miss the starting point, leading to misalignment or errors during application. To counter this, Century Printing and Packaging can incorporate an eye mark on the label or liner, ensuring precise application every time. CP&P works closely with clients to anticipate and address these challenges, ensuring a smooth application process regardless of the packaging type.

Though clear labels can become a powerful tool for modern brands, they can also be a hassle to print and apply if the proper steps, competence, and mastery of the team aren’t where they need to be. A deep understanding of the materials, processes, and potential pitfalls makes Century Printing and Packaging confident in their ability to navigate the complexities of clear-label production. Their caliber and extensive experience have taught them the importance of meticulous planning, from the initial design stages to the final application, as well as from cutting-edge pre-press design techniques to selecting the appropriate ink placement. CP&P has experimented and refined its process, so you don’t have to.

If you’re ready to take your product packaging to the next level with clear labels, contact Century Printing and Packaging today. Let us put our expertise to work for you and help you create labels that stand out.

Century Printing and Packaging had the opportunity to engage in in-depth conversations about emerging trends, innovative technologies, sustainability practices, and best business strategies in the label printing sector. As members for the past three years, Ben and Neil value the opportunity to participate in this event, which provides a platform for uncovering new best practices, networking with peers and vendors, and gaining insights into the industry’s future.

Century Printing and Packaging had the opportunity to engage in in-depth conversations about emerging trends, innovative technologies, sustainability practices, and best business strategies in the label printing sector. As members for the past three years, Ben and Neil value the opportunity to participate in this event, which provides a platform for uncovering new best practices, networking with peers and vendors, and gaining insights into the industry’s future. One of the most valuable aspects of being a member of FLAG is the peer group that Ben and Neil belong to. They meet virtually once a month to discuss business challenges and opportunities, but the annual meeting allows them to engage in person. This year, the collective group spent over four hours sharing insights on industry trends, sales strategies, vendor relationships, and long-term goals. These discussions are crucial for staying competitive and responsive to the shifting market.

One of the most valuable aspects of being a member of FLAG is the peer group that Ben and Neil belong to. They meet virtually once a month to discuss business challenges and opportunities, but the annual meeting allows them to engage in person. This year, the collective group spent over four hours sharing insights on industry trends, sales strategies, vendor relationships, and long-term goals. These discussions are crucial for staying competitive and responsive to the shifting market. Another impactful takeaway from FLAG was the numerous opportunities for Ben and Neil to speak with other label companies that use digital presses. Century Printing and Packaging is working on adding an additional digital press to its lineup, so being able to ask questions and weigh options was invaluable for making informed decisions in the future. As CP&P evaluates the digital printing options available, their primary goal is to identify the most efficient solutions that will allow the team to deliver top-quality products to customers at the most competitive prices.

Another impactful takeaway from FLAG was the numerous opportunities for Ben and Neil to speak with other label companies that use digital presses. Century Printing and Packaging is working on adding an additional digital press to its lineup, so being able to ask questions and weigh options was invaluable for making informed decisions in the future. As CP&P evaluates the digital printing options available, their primary goal is to identify the most efficient solutions that will allow the team to deliver top-quality products to customers at the most competitive prices. As digital printing’s growth continues to rise, staying modern and relevant will be pivotal. While flexographic printing remains crucial for high-volume, high-quality labels, digital printing offers indispensable versatility that has become hard to replace.

As digital printing’s growth continues to rise, staying modern and relevant will be pivotal. While flexographic printing remains crucial for high-volume, high-quality labels, digital printing offers indispensable versatility that has become hard to replace.

Material selection is critical, where a delicate balance between value and quality must be struck. Clients often seek materials that are both cost-effective and durable. CP&P has demonstrated exceptional proficiency in identifying this ideal equilibrium, ensuring that the selected materials meet the requisite performance criteria and remain economical, assuring the cost-effectiveness and durability of materials.

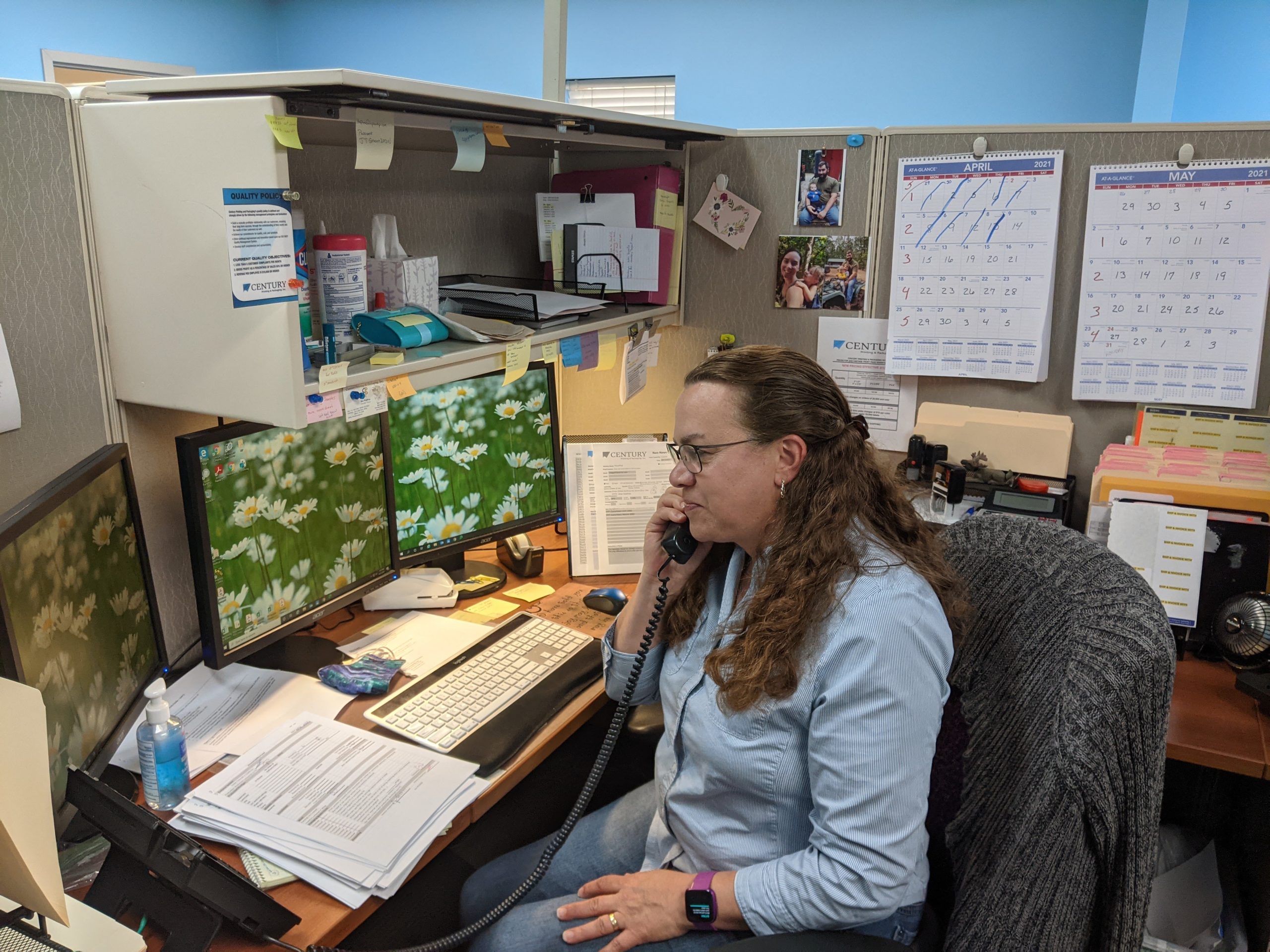

Material selection is critical, where a delicate balance between value and quality must be struck. Clients often seek materials that are both cost-effective and durable. CP&P has demonstrated exceptional proficiency in identifying this ideal equilibrium, ensuring that the selected materials meet the requisite performance criteria and remain economical, assuring the cost-effectiveness and durability of materials. A labeling quote includes a detailed breakdown of all aspects of the label production process. This includes the choice of materials, whether paper or film, the type of laminate or coating to be applied, and the size and configuration of the label rolls. The quote also itemizes any costs associated with tooling, such as tooling required for custom shapes or sizes. This level of detail ensures that clients understand the production process and associated costs, allowing them to make informed decisions that align with their labeling needs and budget constraints.

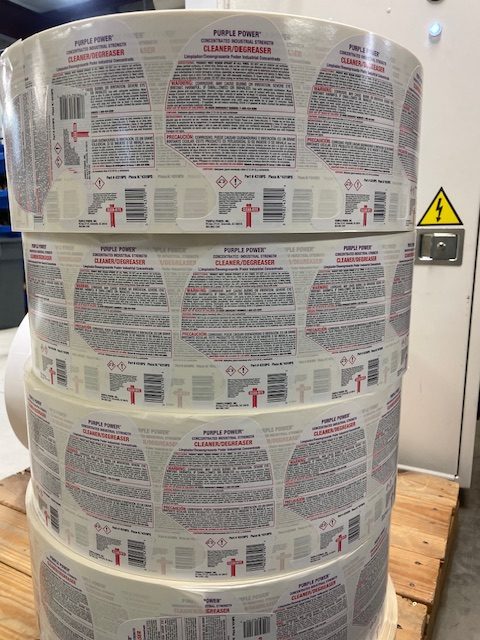

A labeling quote includes a detailed breakdown of all aspects of the label production process. This includes the choice of materials, whether paper or film, the type of laminate or coating to be applied, and the size and configuration of the label rolls. The quote also itemizes any costs associated with tooling, such as tooling required for custom shapes or sizes. This level of detail ensures that clients understand the production process and associated costs, allowing them to make informed decisions that align with their labeling needs and budget constraints. ISO standards provide a framework for companies to establish, maintain, and implement standardized processes and procedures to ensure that every label meets the highest quality standards. One key aspect of CP&P’s ISO quality system is a checklist integrated into its production process. This checklist serves as a comprehensive guide for press operators and managers. It outlines the critical steps and quality checks needed during the label setup and production process. It covers aspects such as ensuring the correct die-cut, verifying that graphics match the proof, and confirming that the right materials are used.

ISO standards provide a framework for companies to establish, maintain, and implement standardized processes and procedures to ensure that every label meets the highest quality standards. One key aspect of CP&P’s ISO quality system is a checklist integrated into its production process. This checklist serves as a comprehensive guide for press operators and managers. It outlines the critical steps and quality checks needed during the label setup and production process. It covers aspects such as ensuring the correct die-cut, verifying that graphics match the proof, and confirming that the right materials are used.

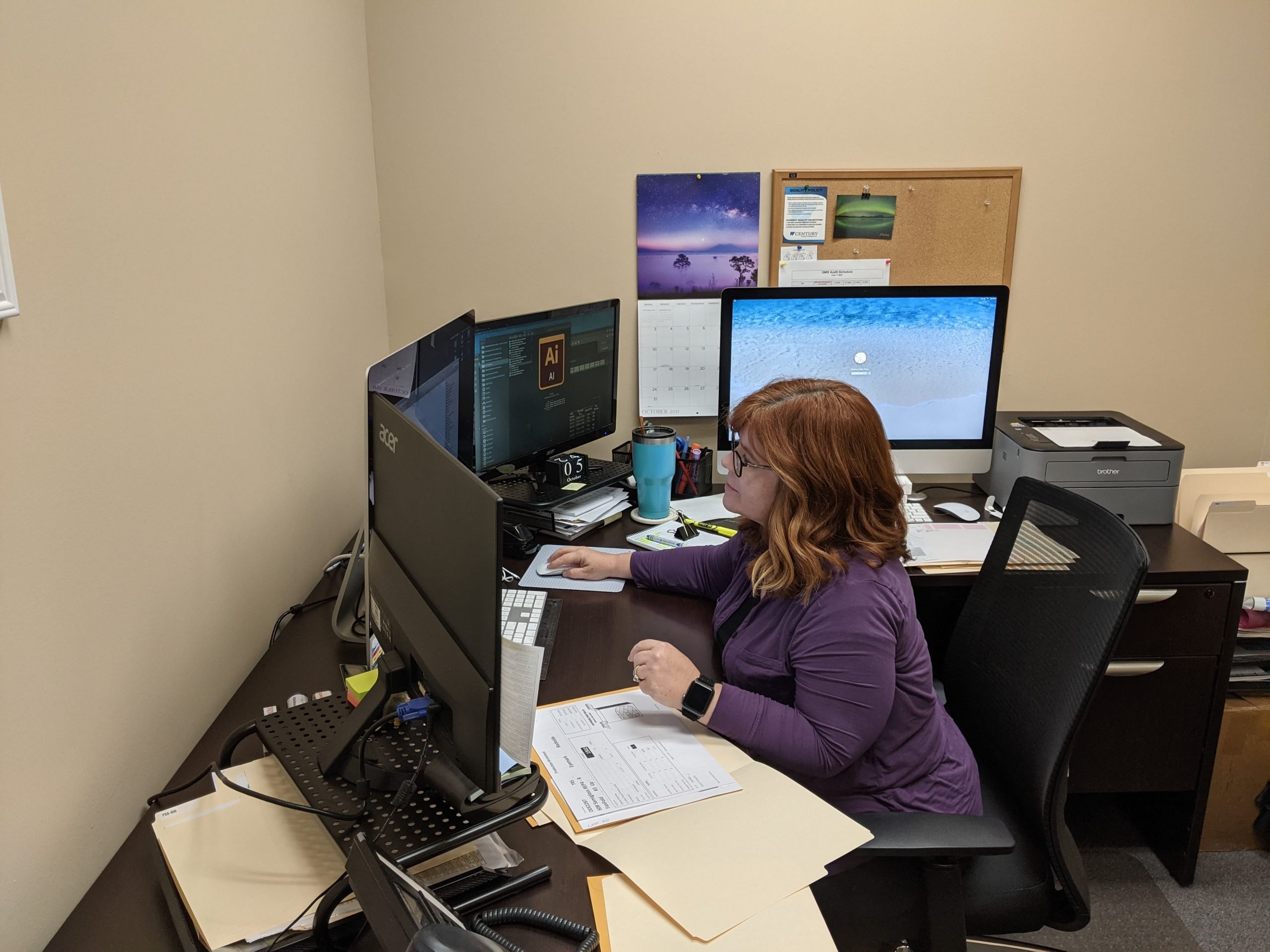

At every pre-press stage, optimization for the best outcome is key. Preparing the artwork starts with the label design for flexo printing. This involves carefully selecting appropriate colors, defining trapping and overprinting settings (which refer to the techniques used to prevent gaps or overlaps between adjacent colors in a print), using printable fonts and point size, and setting up dieline and bleed specifications. A dieline is a graphic element that serves as a template or guide to create a die, which is then used to cut or shape the label substrate.

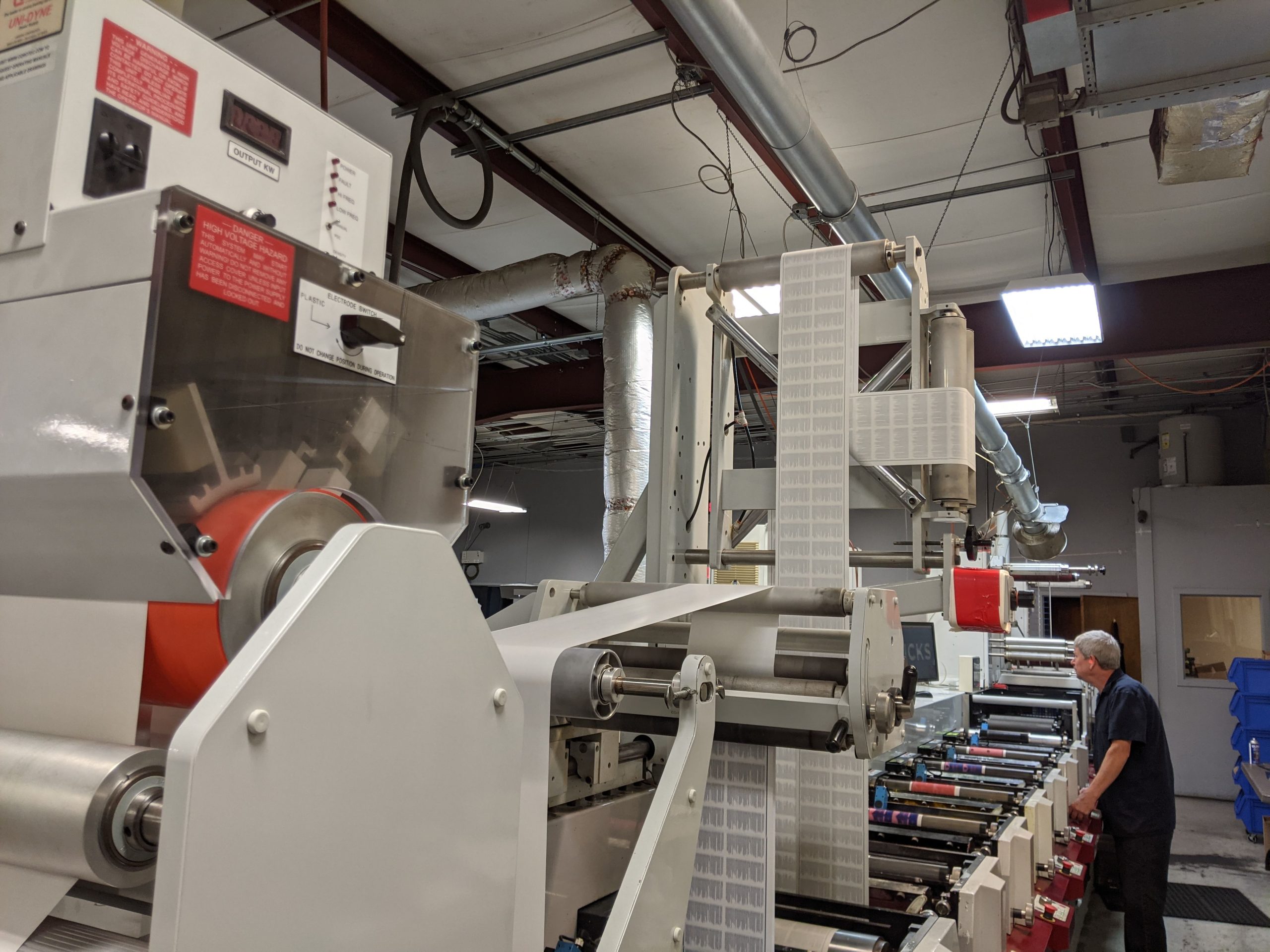

At every pre-press stage, optimization for the best outcome is key. Preparing the artwork starts with the label design for flexo printing. This involves carefully selecting appropriate colors, defining trapping and overprinting settings (which refer to the techniques used to prevent gaps or overlaps between adjacent colors in a print), using printable fonts and point size, and setting up dieline and bleed specifications. A dieline is a graphic element that serves as a template or guide to create a die, which is then used to cut or shape the label substrate. After the prepress steps have been performed, the next order of business is setting up the press. This stage involves choosing the appropriate label substrate based on the application requirements and selecting ink formulations compatible with the preferred substrate. These first steps ensure that the substrate is clean, free from dust or debris, and properly conditioned to minimize static electricity. Ink viscosity adjustments are also conducted to achieve optimal ink transfer and color density to meet desired color specifications.

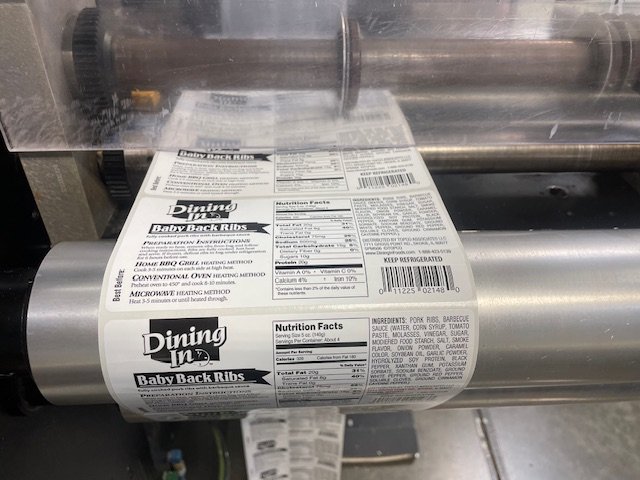

After the prepress steps have been performed, the next order of business is setting up the press. This stage involves choosing the appropriate label substrate based on the application requirements and selecting ink formulations compatible with the preferred substrate. These first steps ensure that the substrate is clean, free from dust or debris, and properly conditioned to minimize static electricity. Ink viscosity adjustments are also conducted to achieve optimal ink transfer and color density to meet desired color specifications. Next, the press setup agenda involves carefully mounting the flexographic plates onto the printing cylinders to ensure proper alignment with the cutting die. Once the plates are firmly secured using tapes or adhesive materials, it’s time to choose the appropriate anilox rolls based on the desired ink coverage and resolution requirements. Fine-tuning the printing pressure settings to achieve optimal contact between the plates, anilox rolls, and substrate is a prerequisite to avoiding excessive pressure, which can lead to plate distortion, wrong color, or substrate deformation.

Next, the press setup agenda involves carefully mounting the flexographic plates onto the printing cylinders to ensure proper alignment with the cutting die. Once the plates are firmly secured using tapes or adhesive materials, it’s time to choose the appropriate anilox rolls based on the desired ink coverage and resolution requirements. Fine-tuning the printing pressure settings to achieve optimal contact between the plates, anilox rolls, and substrate is a prerequisite to avoiding excessive pressure, which can lead to plate distortion, wrong color, or substrate deformation. Post-press setup is just as important as the prepress and press setup stages. Regular maintenance tasks, such as cleaning ink chambers, doctor blades, and anilox rolls, prevent ink buildup and maintain printing consistency. Replacing worn-out or damaged components as needed is a proactive measure to avoid production disruptions. By performing these tasks regularly, you can keep your equipment in top shape, extend its lifespan, and maximize its performance for each label job.

Post-press setup is just as important as the prepress and press setup stages. Regular maintenance tasks, such as cleaning ink chambers, doctor blades, and anilox rolls, prevent ink buildup and maintain printing consistency. Replacing worn-out or damaged components as needed is a proactive measure to avoid production disruptions. By performing these tasks regularly, you can keep your equipment in top shape, extend its lifespan, and maximize its performance for each label job.