Greg Hrinya, Editor – 9.05.24

This thriving South Carolina-based label converter has found success with foresight and innovation.

In 1997, three family members with complementary skill sets set forth on building a printing business. With entrepreneurship in its blood, the Waldrop family established Century Printing & Packaging to fill a need that was missing in South Carolina. Don Waldrop, along with his sons Ben and Neil, leased an office space and initially ran their first 7″ Comco press out of a converted bathroom. More than 25 years later, Century has emerged as one of the leading label converters in the Southeast US.

Don entered the business with years of executive leadership experience, while Ben boasted sales experience and local knowledge of the region. Neil, meanwhile, had just completed his Graphic Communications degree at Clemson. Neil subsequently worked at Clemson’s Industry Training & Research Facility before deciding he wanted to embark on a different path.

Prior to establishing Century, Don and Ben had been operating a textile related business. However, the textile industry had been slowly migrating overseas. The Waldrops joined forces and identified flexographic printing as the perfect opportunity.

“The writing was on the wall, because textiles were going overseas,” explains Neil. “We knew we needed to get into something else, and there was no flexo label printing operation in this area, which was shocking.”

“When we sat down and started talking about the business, Dad and I realized very early on we could use my sales experience and lean on his years of leadership,” adds Ben. “In terms of printing, we had to talk through every job with Neil to see if the jobs were even possible. We quickly learned about the printing business. As we went on, we were able to get our hands around it.”

Growth came swiftly, as the Waldrops soon realized they needed a second Comco press to meet demand. However, the landlord did not have room for a second press, so the Waldrops moved the company to Greer, SC, in 2001, and signed a contract to build the company’s current location.

“We opened this facility with eight employees, and we had so much space we didn’t know what we were going to do with all of it,” says Neil. “In 2003, we bought our first 10″ Mark Andy 2200 press, which was six colors, and then we later added two more stations.”

Today, Century operates out of its 16,000-square-foot facility in Greer, running five presses. Ben serves as president and Neil functions as the COO. In those roles, Ben oversees sales and the front office while Neil presides over production and the warehouse. They are supported by a strong team. Connie Vincent is the VP of operations and looks over prepress, along with various management roles in the overall business. Matthew Hammond is the VP of sales, while Allen Smith manages the pressroom. Roger Thibault also keeps the equipment and building in top working condition. Plus, Natalie Schmal manages finishing, and Tonya Gilliam runs shipping and the warehouse. Don, meanwhile, is enjoying retirement.

“We believe that staying in this space and not expanding has made us a better company because it has made us incredibly efficient,” notes Ben. “That mindset has always helped us. Between our ISO 9001 certification and our limited space, we have been able to drive efficiency in our manufacturing.”

Century found immediate success with advertisement labels placed on newspapers. At the height of the company’s newspaper label printing, it was selling over 100 million labels annually to papers all over the country – and even internationally. While Century still has 30% of its revenue in newspaper labeling, the company has diversified into numerous other areas.

“The newspaper industry boomed for us, but we were also doing labels for chemicals and food,” comments Ben. “And we’re still very much in those businesses, along with beverage and general industrial labels.

“We often talk about inflection points in the company,” adds Ben. “When we entered the newspaper business we realized we needed to have a fan-folded machine that could fan-fold without perf, so as the newspaper facilities increased the speeds of production, we needed to react with a stronger liner so the labels would not break at the perf during application. By scoring the liner instead of perfing it, we were able to accomplish this goal. Neil worked with an engineering company to produce an off-line fan-folded machine exclusively for the newspaper business, and we have a patent on it. It was a major turning point to allow us to handle large accounts.”

“Another pivotal moment for us was when we started making plates in-house,” adds Neil. “We were running tons of plates in our newspaper labels heyday, and we started a second shift. But we couldn’t keep enough plates in here to keep two shifts going. We were paying overnight charges every day to get plates from Charlotte to here. It got to the point where it didn’t make any sense. We converted some warehouse space to add platemaking equipment from Esko and what was JVI and is now APR.”

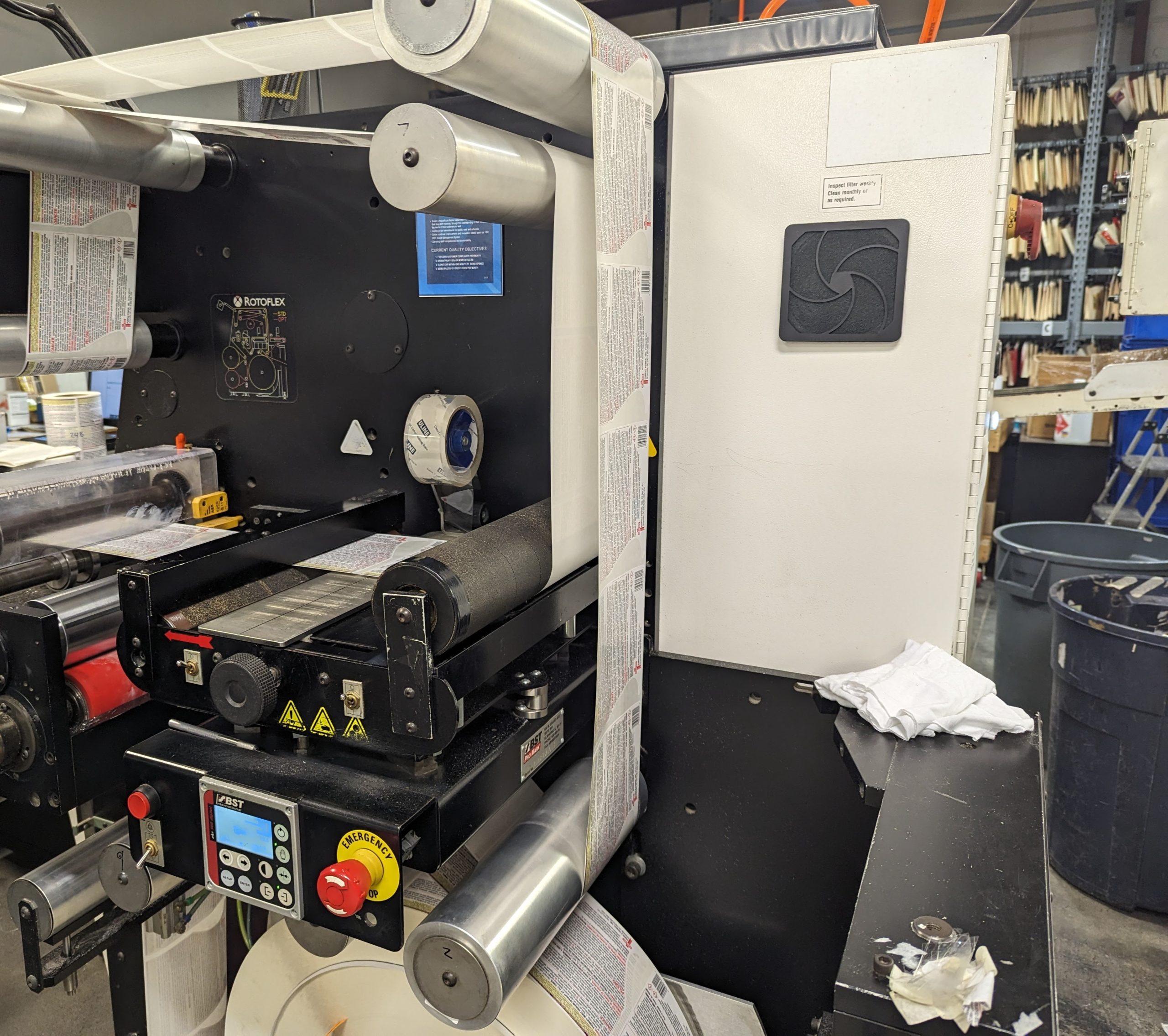

Partnerships have been key for Century, too. As a Mark Andy flexo printing shop, the company has three Mark Andy 2200 flexo presses, a Mark Andy Performance Series P5, and a Mark Andy Digital Series IQ hybrid press. In the future, the company will explore consolidation of two of the 2200s, replacing them with a standalone digital press.

“We have done a good job of realizing when we need new equipment, either producing it ourselves or going out into the market and finding what we need,” says Ben.

Wilson Manufacturing has emerged as another important partner, helping Century with numerous diecutting challenges, as well as providing education and insight into the growing flexible die space.

“Wilson has been a great partner for us,” states Ben. “They stand behind their product, and they have a willingness to lend expertise on difficult diecutting challenges. As we have gotten into more exotic materials, they have been very helpful on how to design dies with the right materials for what we’re trying to accomplish. I will also say we were late to the flexible die game, and they very much helped persuade us to go in that direction. That has been a great strategic move for us.”

Trendsetters

The Waldrops have always been quick to recognize future trends and how they will impact business. They were quick to invest in new flexo technology when the time came, and they saw the potential for newspaper decline in 2019 – prompting a pivot. Century Printing & Packaging also invested in digital hybrid technology before most other label converters, recognizing a need and value for its customers.

In 2018, Century made the calculated decision to enter the digital label printing arena with Mark Andy’s Digital One press. “We invested in one of the original Digital One presses,” recalls Neil. “It wasn’t really ideal for our markets, as we print a lot of clear films and need white. But that press got us started in the digital world, figuring out pricing and where to sell certain jobs, how to figure out which jobs to put on which press. That investment started us way down that path, and it was a good stepping stone for what we have today.”

In 2022, Century continued down the digital path by installing a Mark Andy Digital Series IQ. The company has enjoyed a true partnership with Mark Andy, as this press – with digital assets from Domino – was just the fifth Digital Series IQ that Mark Andy had sold.

“We realized after experimenting with the Digital One that we needed something to be able to print on clear materials – and a wide variety of materials – and we needed the speed that the DSIQ brought to the table,” explains Ben. “We also needed to be able to produce large runs with multiple SKUs. We were beginning to get some customers that had the same size and same material, but they might have 25-30 SKUs. This allowed us to service that market.”

“There was a comfort level with Mark Andy, and that was a big part of going with this press,” adds Neil. “Knowing the flexo side of Mark Andy’s business and having redundancy was key, as we have a turnbar, and delam and relam units – exactly what’s on our P5. We communicate a lot with Mark Andy about what they offer and what we want. The press has expanded the markets we’ve been in, but it has also opened up doors to new markets.”

The same mindset for investing in new equipment could be associated with applications, too. Ben and Neil have identified RFID labeling as the next wave for Century. Plus, the company will continue to expand its flexible packaging capabilities.

With Walmart rolling out RFID mandates, Century wasted no time in taking a deep dive into the market. “We have a major customer of ours that sells to Walmart, and they came to us for help,” comments Ben. “We went to the conference down at Auburn, researched what was involved, talked to all the players, and then helped that customer meet the Walmart requirements. Once we were able to do that, we figured we might as well take that knowledge and use it as part of our growth path.”

In the future, Century is exploring printers and encoders, as well as the wet application of RFID inlays directly into prime labels, to add to the business’ capabilities. “We also think there is a lot of potential in the industrial RFID market,” adds Ben.

He continues, “Not just for prime labeling but for inventory tracking, especially as supply chain and logistics continue to be a focus for corporate leadership in an era of 7-8% interest rates. We believe this is a market we can grow in that we’re a good fit for.”

Making the ‘PASS’

For Century Printing & Packaging, addressing the latest trends has not stopped at investing in new equipment. In fact, after noticing a gap in the market, the Waldrops embarked on a journey to design their very own ERP software system. Standing for Palmetto Advanced Software Systems, the corporation that owns the software, PASS is a cloud-based ERP system that Century uses to manage all orders from the time they come into the front office to the time the jobs are shipped out of the back of the facility.

“PASS demonstrates how if we see a problem, we’re willing to innovate to solve the problem,” explains Ben. “The system manages every step and ensures that each order goes through the same process, and it tracks every order. We originally had a database program that we used for years, but we needed something new. We then engaged with a group to help us program this cloud-based system over a 2.5 year period. It was a huge undertaking, more than we expected, but we launched it at the beginning of last year internally. PASS is very central to how we operate and how we present information to our customers. It is a big piece of how we’re going to grow as a company.”

The Waldrops scoured the market for software that would fill a void in their operations, even analyzing software programs that were not specific to printing. After searching the market for a solution, they realized they were better served developing a homegrown system. Ben and Neil subsequently relied heavily on employee feedback when designing the software. They wanted to make sure the team’s needs and requirements were being met.

“PASS has really helped us understand what’s happening in our plant at any given second,” remarks Ben. “We have a dashboard we use that is located on our monitors and shows what has to ship today, what the positions are, and each work station everybody is logged onto. The software shows them what their next task is and what they need to do. The press operators then enter the data, and the same goes for finishing and shipping.

“This is built to expand and have multiple APIs, so we can plug the data into other software systems,” adds Ben. “PASS is very tied in with our Esko prepress software, so there’s automatic two-way conversation. When a graphic file is approved, it automatically lets PASS know through a series of steps. And the same happens with shipping. Once the job gets to shipping, the tracking number is automatically downloaded into PASS. We built it to be functional across multiple stages, across multiple software packages.”

By leaning into automation via PASS, Century has enabled its employees to spend more time on mission-critical jobs that require attention.

“PASS allows our people to spend time utilizing their skills for more difficult situations or higher-level tasks rather than just basic data entry,” says Neil. “We don’t want people wasting time looking for something when the information is right there to be communicated. Your time is then spent running the press or on customer service. With this system, we’re able to process more orders and execute them with the proper information.”

Building culture

As a small, family-run company consisting of 25 employees, the Waldrops have prioritized their community – both inside and outside of the manufacturing facility at 1904 Suber Mill Road. In addition to encouraging employees to get involved in the community, which is a pillar for the Waldrops, the Century Printing & Packaging team receives a host of benefits for contributing to the company’s success. In turn, tenure has been exceptionally strong.

“I know family atmosphere is an overdone description, but I would say it fits here because a family runs the business,” explains Ben. “We have been very fortunate to have some great employees who have been with us for 15 years. We have a lot in the 10-12 range, too, so we have done a good job building a community within this group.

“We do both big and small things to recognize our employees,” adds Ben. “We’ll host a lunch each month to recognize and celebrate employee anniversaries. We also pay out a quarterly bonus if we hit certain metrics, and everybody in the company participates. And that can be substantial, no matter what your position or role is.”

The Waldrops have emphasized a culture of positivity, as well. By investing in cross-training, each employee has the ability to step in and help their teammates – with the goal of always finding a solution.

“When we start out meetings, everyone has to say one positive thing,” says Neil. “It can be personal or it can be work related. We had one person say this morning that they appreciate the other people they’re working with because other people are willing to step in when they see a need. And we don’t even have to ask. That’s the kind of culture we have, where people will take it upon themselves to help out.”

Part of building the Century culture has involved association involvement. By joining groups like FLAG and TLMI, the Waldrops have been able to gain insight and expertise into how they run their business. Plus, they can share best practices to implement with their South Carolina-based team.

Neil’s first step was joining FLAG, and the company recently made the move to join TLMI, as well.

As a part of the manufacturing community in the upstate region of South Carolina, the company is also active in SCMEP and the Upstate Manufacturing Sector Partnership, SENPA, Greater Greer Chamber of Commerce, and the Brewer’s Association.

“We spend a lot of time on non-label organizations for sales,” states Ben. “And we realized several years ago we needed to do a better job networking in our industry to gain shared knowledge and intelligence. Neil joined FLAG as a first step, and he’s gotten a ton of good feedback and resources from his involvement. We have had a lot of success with their peer groups, which have been very valuable to us as a company. Neil has been to the Annual Meeting several times, and I went for the first time this year and got a lot out of it. Because that has been so successful, we joined TLMI.

“We will also become more active attendees at Labelexpo Americas, as well,” adds Ben.

“We’re not just going there and walking the show floor, we’ll also be engaged in seminars and meeting with people. We’re booked from the time we land to the time we leave. We think that networking in our industry is really valuable to us.”

Splicing ensures that labels are seamlessly joined together, whether applied by hand or machine. When labels are machine-applied, the splice must be stronger to withstand the tension from the applicator. In contrast, labels applied by hand require a less intense splice. Understanding how the label will be applied is essential for determining the type of splice needed. This attention to detail ensures that labels are prepared correctly for their intended use, highlighting Century’s commitment to delivering high-quality products tailored to their customers’ needs.

Splicing ensures that labels are seamlessly joined together, whether applied by hand or machine. When labels are machine-applied, the splice must be stronger to withstand the tension from the applicator. In contrast, labels applied by hand require a less intense splice. Understanding how the label will be applied is essential for determining the type of splice needed. This attention to detail ensures that labels are prepared correctly for their intended use, highlighting Century’s commitment to delivering high-quality products tailored to their customers’ needs. Finishing is a vital step in the label printing process that can often get overlooked. However, it’s the final touch that guarantees your labels not only look great but are also ready to be used as intended. At Century Printing and Packaging, each member of the finishing department understands the nuances of this final stage, ensuring even the most complex jobs are handled with precision. The customer’s proof serves as a reference point throughout the process, ensuring that the finished labels match the customer’s specifications. This attention to detail prevents errors and saves time and resources by catching any issues early in the process. By prioritizing quality control and proofs, Century Printing and Packaging demonstrates its commitment to delivering superior results with enhanced appeal for every label.

Finishing is a vital step in the label printing process that can often get overlooked. However, it’s the final touch that guarantees your labels not only look great but are also ready to be used as intended. At Century Printing and Packaging, each member of the finishing department understands the nuances of this final stage, ensuring even the most complex jobs are handled with precision. The customer’s proof serves as a reference point throughout the process, ensuring that the finished labels match the customer’s specifications. This attention to detail prevents errors and saves time and resources by catching any issues early in the process. By prioritizing quality control and proofs, Century Printing and Packaging demonstrates its commitment to delivering superior results with enhanced appeal for every label.

One major factor that has affected the beer industry is the shortage of glass. Coming out of the pandemic, supply chain issues have resulted in many beer brands opting to purchase unprinted cans and add their own labels as needed. This not only offers more flexibility in terms of branding and design, but it also allows breweries to save money by only ordering the exact amount of cans they need at any given time.

One major factor that has affected the beer industry is the shortage of glass. Coming out of the pandemic, supply chain issues have resulted in many beer brands opting to purchase unprinted cans and add their own labels as needed. This not only offers more flexibility in terms of branding and design, but it also allows breweries to save money by only ordering the exact amount of cans they need at any given time.