As we stand at the midpoint of the year, Century Printing and Packaging takes a moment to reflect on the milestones achieved, strides made, and advancements moving our industry. CP&P has seen great progress and has established strategic initiatives that set the stage for the next six months to improve and innovate for every client.

Century Printing and Packaging has achieved remarkable success this year, having sold over 85 million labels and fulfilled over 3,000 orders. This substantial volume highlights CP&P’s ability and dedication to meeting high demand while maintaining top-notch execution. The presence of a well-organized team working in unison has been instrumental in reaching these impressive milestones.

Let’s uncover some direct impacts to better understand what led to Century Printing and Packaging’s success in the year’s first half.

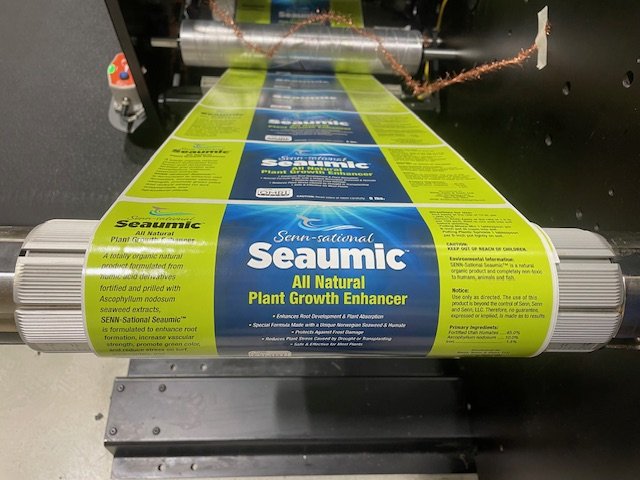

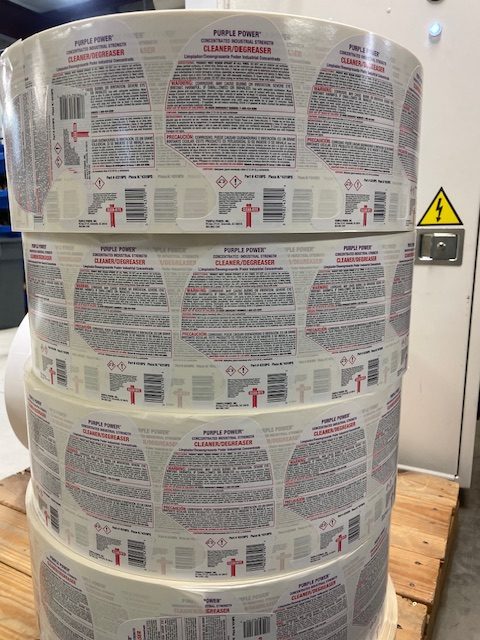

According to an article on LinkedIn, the Chemical Resistant Labels Market is projected to grow by 13.6% from 2024 to 2031. CP&P has focused on the chemical segment, which has led to their growth and expertise in providing specialized labeling solutions for this industry. Keeping up with this rapidly growing market shows their ability to meet the specific needs of chemical manufacturers, ensuring safety and compliance through durable and long-lasting labeling solutions.

Another reason for the remarkable success witnessed in 2024 is the sale of RFID labels. Century Printing and Packaging has taken the necessary steps to integrate itself into the new world of RFID labeling, not only to understand the industry’s changes but also to position the team as experts in the space. CP&P also intends to invest in encoding equipment for RFID labels within the year, bolstering its capability to stay current with future RFID trend needs.

In line with technological advancements, CP&P is exploring the purchase of a second digital press by the end of the year. This investment will empower the team to proactively assess and respond to customers’ evolving needs. By incorporating additional production bandwidth through introducing new presses, CP&P will have the capacity to accommodate a broader range of customer requirements.

Next, let’s examine market dynamics and customer trends that are significantly contributing to CP&P’s 2024 growth.

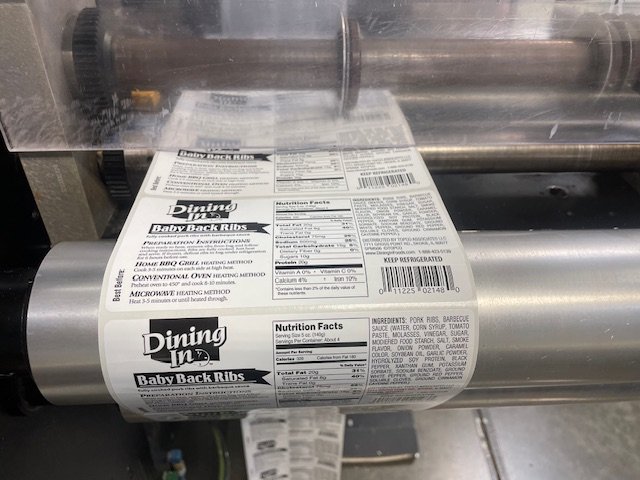

We are all experiencing the impact of inflation in one way or another, but one positive effect is the growing favor for store brands over name brands. A significant number of CP&P’s customers produce store brands, and this change in consumer preference has directly boosted sales. You may have already observed the trend of store brands occupying more space in shopping carts as consumers actively seek budget-friendly alternatives to name brands. Read more about this trend in the Wall Street Journal.

In contrast to last year, when supply chain disruptions presented significant challenges, 2024 has witnessed more stable supply chains. Century Printing and Packaging has taken proactive measures by expanding its pool of materials suppliers. This move ensures cost competitiveness and swift production timelines without any delays. The newfound stability has enabled CP&P to prioritize delivering consistent quality and reliability to their customers, even amid ongoing uncertainties in global supply chains.

Lastly, let’s dive into some strategic initiatives that CP&P has taken that will lead them into a flourishing 2025.

Century Printing and Packaging has conducted extensive studies on setup costs in response to customers’ heightened price sensitivity. This research has allowed them to refine existing pricing models, ensuring competitive quotes while maintaining profitability. By understanding the detailed costs of each production run, CP&P can provide customers with the best possible pricing without compromising quality.

Century’s workforce remains a cornerstone of their yearly success. CP&P takes pride in having a stable and dedicated team with the right people in the right positions, driving operations forward without interruption. A unified team, all pushing in the same direction, will fortify CP&P against any challenges that come their way in the second half of the year.

Looking ahead to the second half of 2024, Century Printing and Packaging is confident in its ability to continue providing high-value labels at every price point to its customers. The strategic investments mentioned above, strong production capabilities, and stable supply chains position CP&P well for future growth.

Century Printing and Packaging wouldn’t be here today without the support of its customers, partners, and team members for their continued collaboration and dedication. Together, CP&P is looking forward to achieving even greater milestones in the coming months and years.

Thank you for being a part of the journey.

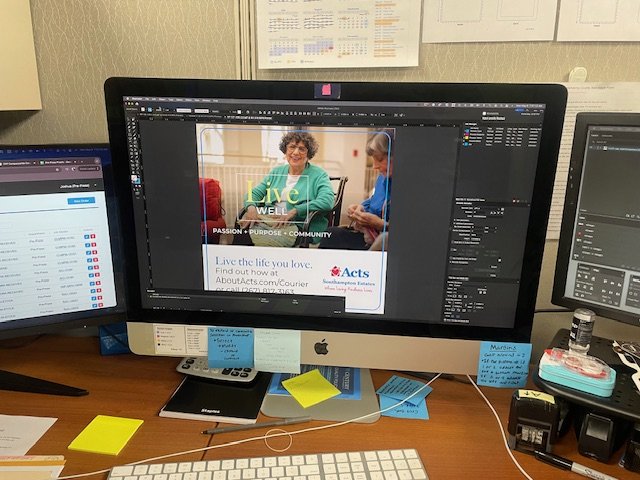

At every pre-press stage, optimization for the best outcome is key. Preparing the artwork starts with the label design for flexo printing. This involves carefully selecting appropriate colors, defining trapping and overprinting settings (which refer to the techniques used to prevent gaps or overlaps between adjacent colors in a print), using printable fonts and point size, and setting up dieline and bleed specifications. A dieline is a graphic element that serves as a template or guide to create a die, which is then used to cut or shape the label substrate.

At every pre-press stage, optimization for the best outcome is key. Preparing the artwork starts with the label design for flexo printing. This involves carefully selecting appropriate colors, defining trapping and overprinting settings (which refer to the techniques used to prevent gaps or overlaps between adjacent colors in a print), using printable fonts and point size, and setting up dieline and bleed specifications. A dieline is a graphic element that serves as a template or guide to create a die, which is then used to cut or shape the label substrate. After the prepress steps have been performed, the next order of business is setting up the press. This stage involves choosing the appropriate label substrate based on the application requirements and selecting ink formulations compatible with the preferred substrate. These first steps ensure that the substrate is clean, free from dust or debris, and properly conditioned to minimize static electricity. Ink viscosity adjustments are also conducted to achieve optimal ink transfer and color density to meet desired color specifications.

After the prepress steps have been performed, the next order of business is setting up the press. This stage involves choosing the appropriate label substrate based on the application requirements and selecting ink formulations compatible with the preferred substrate. These first steps ensure that the substrate is clean, free from dust or debris, and properly conditioned to minimize static electricity. Ink viscosity adjustments are also conducted to achieve optimal ink transfer and color density to meet desired color specifications. Next, the press setup agenda involves carefully mounting the flexographic plates onto the printing cylinders to ensure proper alignment with the cutting die. Once the plates are firmly secured using tapes or adhesive materials, it’s time to choose the appropriate anilox rolls based on the desired ink coverage and resolution requirements. Fine-tuning the printing pressure settings to achieve optimal contact between the plates, anilox rolls, and substrate is a prerequisite to avoiding excessive pressure, which can lead to plate distortion, wrong color, or substrate deformation.

Next, the press setup agenda involves carefully mounting the flexographic plates onto the printing cylinders to ensure proper alignment with the cutting die. Once the plates are firmly secured using tapes or adhesive materials, it’s time to choose the appropriate anilox rolls based on the desired ink coverage and resolution requirements. Fine-tuning the printing pressure settings to achieve optimal contact between the plates, anilox rolls, and substrate is a prerequisite to avoiding excessive pressure, which can lead to plate distortion, wrong color, or substrate deformation. Post-press setup is just as important as the prepress and press setup stages. Regular maintenance tasks, such as cleaning ink chambers, doctor blades, and anilox rolls, prevent ink buildup and maintain printing consistency. Replacing worn-out or damaged components as needed is a proactive measure to avoid production disruptions. By performing these tasks regularly, you can keep your equipment in top shape, extend its lifespan, and maximize its performance for each label job.

Post-press setup is just as important as the prepress and press setup stages. Regular maintenance tasks, such as cleaning ink chambers, doctor blades, and anilox rolls, prevent ink buildup and maintain printing consistency. Replacing worn-out or damaged components as needed is a proactive measure to avoid production disruptions. By performing these tasks regularly, you can keep your equipment in top shape, extend its lifespan, and maximize its performance for each label job.

As the majority of our society has pivoted digitally to obtain their daily news sources, the number of front pages available for advertising labels has steadily declined. CP&P has adapted to this downturn in demand for advertising labels by pivoting to the food, beverage, and other key markets. They have also leveraged the power of their hybrid press, added in 2022, which has opened up their capacity in plate making.

As the majority of our society has pivoted digitally to obtain their daily news sources, the number of front pages available for advertising labels has steadily declined. CP&P has adapted to this downturn in demand for advertising labels by pivoting to the food, beverage, and other key markets. They have also leveraged the power of their hybrid press, added in 2022, which has opened up their capacity in plate making.