As attention spans for consumers get shorter and the push for environmental friendliness grows, product labels are expected to check many boxes. An increasing preference for a “no packaging” aesthetic has undoubtedly introduced a significant playing field for clear labels. These transparent labels effectively highlight products without occupying excessive packaging real estate, creating a more simplistic yet distinct display on shelves. However, producing these high-quality clear labels comes with challenges. For 27 years, the Century Printing and Packaging team has perfected the art of clear labeling, tackling these technical obstacles head-on. Their aptitude for finding solutions has armed them with the knowledge and techniques required to produce clear labels as an uptick in demand continues.

Clear labels can be used in various ways depending on what brands are looking to achieve. For example, brands aiming to reduce their environmental impact might want to consider a clear label over a more traditional label with a white background to showcase a cleaner, more sustainable appearance. Clear labels can also be a strategic choice when enhancing product visibility and standing out on shelves to consumers. These labels vary in clarity, ranging from slightly translucent to almost invisible, offering versatility depending on the product and packaging.

Despite the seemingly simple look, more goes on beneath the surface to achieve this sleek, modern appearance that resonates with today’s consumers.

The very nature of clear materials means that any coating or laminate must be carefully chosen and applied to avoid cloudiness or opacity. Century Printing and Packaging understands that even the slightest misstep can diminish the label’s clarity, compromising the “no packaging” look many clients seek. To achieve this, CP&P employs advanced techniques to ensure that protective layers enhance, rather than detract from, the label’s transparency.

Maintaining clarity in clear labels is crucial, but it goes beyond ensuring the material remains transparent. It also involves the label being applied correctly for the end user and firmly adhering to the packaging, considering factors such as the surface tension of the packaging material, the type of adhesive used, and the conditions under which the label will be applied. The label needs to not only look good but also perform well by adhering securely to various surfaces without peeling or bubbling. This balance between visual appeal and functional reliability is an aspect that CP&P strives to strike just right.

Maintaining clarity in clear labels is crucial, but it goes beyond ensuring the material remains transparent. It also involves the label being applied correctly for the end user and firmly adhering to the packaging, considering factors such as the surface tension of the packaging material, the type of adhesive used, and the conditions under which the label will be applied. The label needs to not only look good but also perform well by adhering securely to various surfaces without peeling or bubbling. This balance between visual appeal and functional reliability is an aspect that CP&P strives to strike just right.

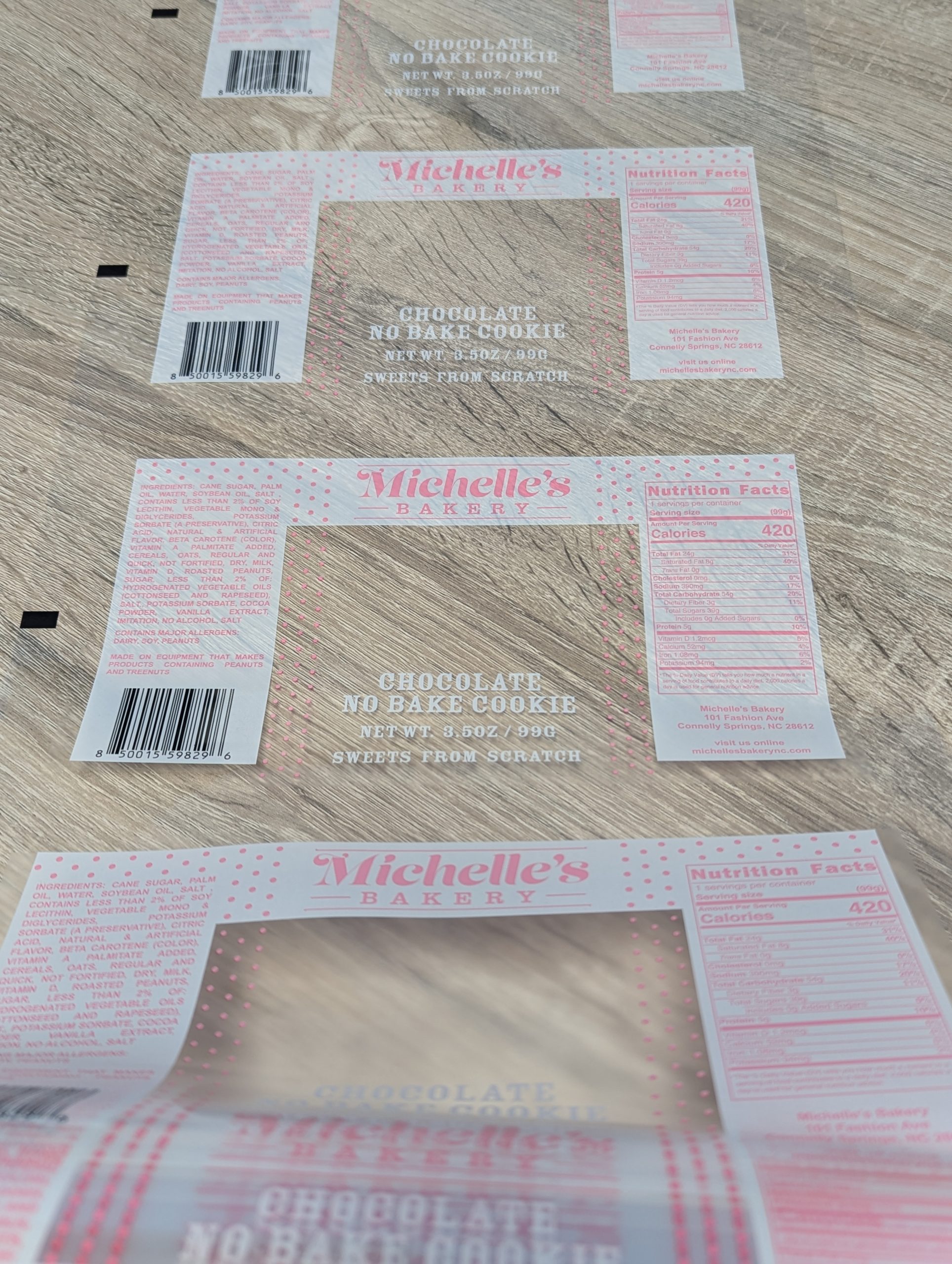

When it comes to successfully printing complex, colorful designs onto a clear label, behind-the-scenes skillfulness will prevent many problems from arising. Without a white background, colors can appear washed out, lacking the vibrancy crucial for an eye-catching label. To address this, a white ink underlay is applied, providing a bright base that allows the colors to pop. This technique requires precision in design and execution to ensure that the white ink is applied only to the necessary parts of the label without overpowering the design. In some cases, double hits of white can be used to achieve the desired opacity and color intensity.

Another technique CP&P utilizes is reverse printing, where the design is printed on the underside of the label. This method protects the printed image while allowing it to be viewed through the clear material, offering a unique and durable labeling option.

Another technique CP&P utilizes is reverse printing, where the design is printed on the underside of the label. This method protects the printed image while allowing it to be viewed through the clear material, offering a unique and durable labeling option.

Producing a clear label doesn’t end after it’s printed. Unless the post-printing stage of the label-making process is planned ahead of time, there is no guarantee that the application process will be easy and stress-free. Automatic label applicators, which rely on sensors to detect the edges of labels, can struggle with clear materials. The transparency of the label can cause the applicator to miss the starting point, leading to misalignment or errors during application. To counter this, Century Printing and Packaging can incorporate an eye mark on the label or liner, ensuring precise application every time. CP&P works closely with clients to anticipate and address these challenges, ensuring a smooth application process regardless of the packaging type.

Though clear labels can become a powerful tool for modern brands, they can also be a hassle to print and apply if the proper steps, competence, and mastery of the team aren’t where they need to be. A deep understanding of the materials, processes, and potential pitfalls makes Century Printing and Packaging confident in their ability to navigate the complexities of clear-label production. Their caliber and extensive experience have taught them the importance of meticulous planning, from the initial design stages to the final application, as well as from cutting-edge pre-press design techniques to selecting the appropriate ink placement. CP&P has experimented and refined its process, so you don’t have to.

If you’re ready to take your product packaging to the next level with clear labels, contact Century Printing and Packaging today. Let us put our expertise to work for you and help you create labels that stand out.

Manufacturers are scrambling to find new supply lines and vendors. Shortages from food, chemicals, lumber, metals, microchips, rubber goods, paper, laminates, and countless other goods have moved businesses from a competitive price focus to sheer availability. Shortages and availability only tighten the vise grip of competing manufacturers. Auto manufacturers are now competing with consumer electronics for computer chips. Before the storm, each had different suppliers and there was no shortage. During the storm, you may produce cars, but your computer or television producer has landed in your backyard competing for the same chips.

Manufacturers are scrambling to find new supply lines and vendors. Shortages from food, chemicals, lumber, metals, microchips, rubber goods, paper, laminates, and countless other goods have moved businesses from a competitive price focus to sheer availability. Shortages and availability only tighten the vise grip of competing manufacturers. Auto manufacturers are now competing with consumer electronics for computer chips. Before the storm, each had different suppliers and there was no shortage. During the storm, you may produce cars, but your computer or television producer has landed in your backyard competing for the same chips. The interdependency within the global economy can best be explained by dominoes falling one over the other throughout a massive display. Everything relates to the other. Loaded ships sit in harbors and can’t get unloaded, a pandemic wiped out 700,000 people in the U.S. alone to date. Many of those were workers and paying taxes. The printing and packaging industry is experiencing supply and material increases between 7-12%, if not more. Polypropylene resin has increased 150% since January of 2020, and PET resin has risen over 20% in the same period (CDI October 2021 Report). Some Industry experts are projecting continued shortages of raw material and polymers to last through Q4 2022.

The interdependency within the global economy can best be explained by dominoes falling one over the other throughout a massive display. Everything relates to the other. Loaded ships sit in harbors and can’t get unloaded, a pandemic wiped out 700,000 people in the U.S. alone to date. Many of those were workers and paying taxes. The printing and packaging industry is experiencing supply and material increases between 7-12%, if not more. Polypropylene resin has increased 150% since January of 2020, and PET resin has risen over 20% in the same period (CDI October 2021 Report). Some Industry experts are projecting continued shortages of raw material and polymers to last through Q4 2022. No reputable and successful business enjoys price increases. Their success is built upon providing a high-quality product/service at a competitive price backed with extraordinary customer service. These companies thrive on long-term customer relationships by exceeding customer expectations. However, there is a point at which even the strongest cannot resist anymore because they start losing money.

No reputable and successful business enjoys price increases. Their success is built upon providing a high-quality product/service at a competitive price backed with extraordinary customer service. These companies thrive on long-term customer relationships by exceeding customer expectations. However, there is a point at which even the strongest cannot resist anymore because they start losing money. Smart companies and businesses are concentrating on minimizing price increases while extending their vendor partnerships to have access to the materials and supplies they need to do their jobs. Increased costs are inevitable given the global market, but smart and reputable suppliers and manufacturers are working with their clients and suppliers to keep prices as low as they can. Material and supply shortages can be expected well into 2022. Plan way ahead to get ahead of this troubling trend. Hopefully, supply, logistics, and labor will self-correct in 2022.

Smart companies and businesses are concentrating on minimizing price increases while extending their vendor partnerships to have access to the materials and supplies they need to do their jobs. Increased costs are inevitable given the global market, but smart and reputable suppliers and manufacturers are working with their clients and suppliers to keep prices as low as they can. Material and supply shortages can be expected well into 2022. Plan way ahead to get ahead of this troubling trend. Hopefully, supply, logistics, and labor will self-correct in 2022. Ben Waldrop, President

Ben Waldrop, President

Shelf life is another consideration when considering the metalized film. What is the oxygen transfer rate required for the product inside? This is the OTR and the measure of how well the film structure will prevent oxygen loss. No one wants stale chips or trail bars! Another shelf life consideration is the water vapor transfer rate (WVTR ). This measures how well the film structure will keep moisture in, or out of the actual bag. The third consideration is the aroma barrier. This is the ability of the film to contain the product’s scent. This is very important in food-grade packaging.

Shelf life is another consideration when considering the metalized film. What is the oxygen transfer rate required for the product inside? This is the OTR and the measure of how well the film structure will prevent oxygen loss. No one wants stale chips or trail bars! Another shelf life consideration is the water vapor transfer rate (WVTR ). This measures how well the film structure will keep moisture in, or out of the actual bag. The third consideration is the aroma barrier. This is the ability of the film to contain the product’s scent. This is very important in food-grade packaging. The advantages of the metalized film are many. Compared to foil it creates a higher barrier at a medium price point where the foil is its own layer of material providing the highest barrier but at a higher cost. In comparison to standardized, or non-metalized films it’s cheaper but with less of a barrier.

The advantages of the metalized film are many. Compared to foil it creates a higher barrier at a medium price point where the foil is its own layer of material providing the highest barrier but at a higher cost. In comparison to standardized, or non-metalized films it’s cheaper but with less of a barrier. Will the fat in a food product oxidize, or bacteria grow inside the package, potentially causing a health risk to the consumer? These are important questions the manufacturer must address with their packaging and printing company.

Will the fat in a food product oxidize, or bacteria grow inside the package, potentially causing a health risk to the consumer? These are important questions the manufacturer must address with their packaging and printing company.

This type of application involves flexographic printing which allows vibrant color and design details. The plates are made onsite cutting down wait times for proofs and getting to production as soon as possible. The film is blown from resin into film and then converted to blank film to printed roll stock. The printer is able to work their magic creating a finished bag that meets or exceeds the customer’s specific graphic, design, and layout content.

This type of application involves flexographic printing which allows vibrant color and design details. The plates are made onsite cutting down wait times for proofs and getting to production as soon as possible. The film is blown from resin into film and then converted to blank film to printed roll stock. The printer is able to work their magic creating a finished bag that meets or exceeds the customer’s specific graphic, design, and layout content. Low Country Kettle (pictured here) is a good example of a pressure-sealed application. The bags are form-fill & seal. There is a barrier layer and the film side is printed with a laminate that is heat sealable so when the manufacturer creates the finished product bag and seals it, it heats to the right temperature and seals the bag. When filling the bags with product Low Country Kettle introduces an air mix that is food grade rated and helps preserve the chips so they stay fresh longer. This prevents the product from going stale before the end-user purchases the product.

Low Country Kettle (pictured here) is a good example of a pressure-sealed application. The bags are form-fill & seal. There is a barrier layer and the film side is printed with a laminate that is heat sealable so when the manufacturer creates the finished product bag and seals it, it heats to the right temperature and seals the bag. When filling the bags with product Low Country Kettle introduces an air mix that is food grade rated and helps preserve the chips so they stay fresh longer. This prevents the product from going stale before the end-user purchases the product.

Today’s packaging and printing material is as diverse and creative as ever. It continues to grow through ingenuity and innovation.

Today’s packaging and printing material is as diverse and creative as ever. It continues to grow through ingenuity and innovation.