Everyone is feeling the pain of inflation from rising prices in goods, materials, chemicals, fuel, and supplies. Whether you serve B2B/B2C every sector is experiencing the avalanche from inflation, supply chain disruptions, Covid19, labor shortages, and a lack of available materials. A trip to the grocery store with empty shelves or purchase limits on certain products is proof enough. It is cliche, but all of these factors have produced the “perfect storm”.

Manufacturers are scrambling to find new supply lines and vendors. Shortages from food, chemicals, lumber, metals, microchips, rubber goods, paper, laminates, and countless other goods have moved businesses from a competitive price focus to sheer availability. Shortages and availability only tighten the vise grip of competing manufacturers. Auto manufacturers are now competing with consumer electronics for computer chips. Before the storm, each had different suppliers and there was no shortage. During the storm, you may produce cars, but your computer or television producer has landed in your backyard competing for the same chips.

Manufacturers are scrambling to find new supply lines and vendors. Shortages from food, chemicals, lumber, metals, microchips, rubber goods, paper, laminates, and countless other goods have moved businesses from a competitive price focus to sheer availability. Shortages and availability only tighten the vise grip of competing manufacturers. Auto manufacturers are now competing with consumer electronics for computer chips. Before the storm, each had different suppliers and there was no shortage. During the storm, you may produce cars, but your computer or television producer has landed in your backyard competing for the same chips.

The printing and packaging industry is not immune to this economic reality. The supply chain gridlock and inflationary pressures have created a challenging environment for the industry. Previously fully stocked vendor’s distribution centers of paper, ink, boxes, laminate, substrate materials, and film are running empty. Lead times of these materials have drastically expanded. Shipping costs due to rising fuel prices and container shortages have only added to the inflationary pressures. These dynamics are unique because the combination of factors has impacted every aspect of business regardless of category. In the past, Wall Street cycles have come and gone, but typically it’s been one industry or just a few that have experienced serious disruption and challenges. Today, EVERY industry and business is affected by these colliding factors.

The interdependency within the global economy can best be explained by dominoes falling one over the other throughout a massive display. Everything relates to the other. Loaded ships sit in harbors and can’t get unloaded, a pandemic wiped out 700,000 people in the U.S. alone to date. Many of those were workers and paying taxes. The printing and packaging industry is experiencing supply and material increases between 7-12%, if not more. Polypropylene resin has increased 150% since January of 2020, and PET resin has risen over 20% in the same period (CDI October 2021 Report). Some Industry experts are projecting continued shortages of raw material and polymers to last through Q4 2022.

The interdependency within the global economy can best be explained by dominoes falling one over the other throughout a massive display. Everything relates to the other. Loaded ships sit in harbors and can’t get unloaded, a pandemic wiped out 700,000 people in the U.S. alone to date. Many of those were workers and paying taxes. The printing and packaging industry is experiencing supply and material increases between 7-12%, if not more. Polypropylene resin has increased 150% since January of 2020, and PET resin has risen over 20% in the same period (CDI October 2021 Report). Some Industry experts are projecting continued shortages of raw material and polymers to last through Q4 2022.

No reputable and successful business enjoys price increases. Their success is built upon providing a high-quality product/service at a competitive price backed with extraordinary customer service. These companies thrive on long-term customer relationships by exceeding customer expectations. However, there is a point at which even the strongest cannot resist anymore because they start losing money.

No reputable and successful business enjoys price increases. Their success is built upon providing a high-quality product/service at a competitive price backed with extraordinary customer service. These companies thrive on long-term customer relationships by exceeding customer expectations. However, there is a point at which even the strongest cannot resist anymore because they start losing money.

Craig Austin writing for PBS said: “Economists surveyed by Bloomberg in October expect inflation to slow to 3.4% next summer and hit 2.6% by the end of the year. While that would be encouraging, it’s still well above the pre-pandemic average of 1.8% and outside the Fed’s target. It’s unclear whether economists are recalibrating their expectations after the October Consumer Price Index report. Regardless, consumers should get used to the higher prices. They’re the new normal.”

Smart companies and businesses are concentrating on minimizing price increases while extending their vendor partnerships to have access to the materials and supplies they need to do their jobs. Increased costs are inevitable given the global market, but smart and reputable suppliers and manufacturers are working with their clients and suppliers to keep prices as low as they can. Material and supply shortages can be expected well into 2022. Plan way ahead to get ahead of this troubling trend. Hopefully, supply, logistics, and labor will self-correct in 2022.

Smart companies and businesses are concentrating on minimizing price increases while extending their vendor partnerships to have access to the materials and supplies they need to do their jobs. Increased costs are inevitable given the global market, but smart and reputable suppliers and manufacturers are working with their clients and suppliers to keep prices as low as they can. Material and supply shortages can be expected well into 2022. Plan way ahead to get ahead of this troubling trend. Hopefully, supply, logistics, and labor will self-correct in 2022.

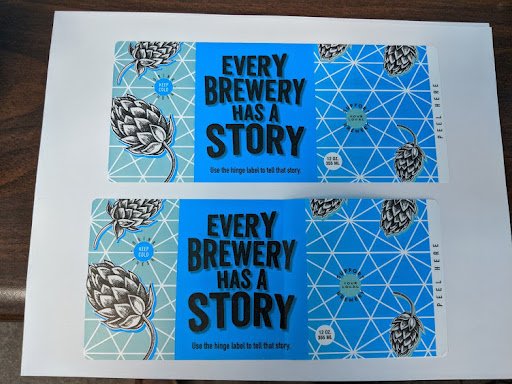

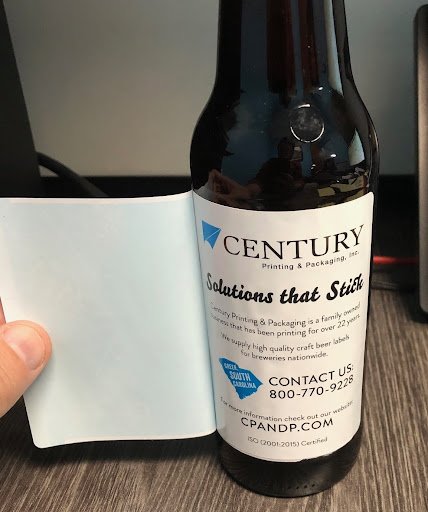

At Century Printing and Packaging we have worked internally to increase efficiency and deliver the same high level of quality that helped us earn our customer’s trust during these challenging days. This combination has allowed us to only raise prices on products once this year. We are well aware of the market fluctuations and we are working with our customers and suppliers to provide solutions despite price increases to supply and rising material costs. We have been printing labels that stick, but have great eye appeal and consistently tell your brand story. We don’t mind tackling a challenging problem if it means we can help you produce something that is more appealing and of higher quality. We have produced labels and packaging for almost 25 years, so trust us to work with you as a partner instead of a job number.

Ben Waldrop, President

Ben Waldrop, President

Century Printing & Packaging

Greer, SC 29651

Tel: 800.344.7509

Like many industries, the craft brewery business has suffered from Covid19. As many parts of the country begin to reopen and indoor gathering rules are relaxed the industry is finding casualties that just couldn’t survive, but also a surge in creativity and innovation.

Like many industries, the craft brewery business has suffered from Covid19. As many parts of the country begin to reopen and indoor gathering rules are relaxed the industry is finding casualties that just couldn’t survive, but also a surge in creativity and innovation. During the pandemic closing tap and tasting rooms was a big blow, but many brewers got creative and produced hand sanitizer and drinking water for local essential industries and first responders. Others pivoted to curbside pick up and delivery which has been allowed in many states.

During the pandemic closing tap and tasting rooms was a big blow, but many brewers got creative and produced hand sanitizer and drinking water for local essential industries and first responders. Others pivoted to curbside pick up and delivery which has been allowed in many states. Ben Waldrop

Ben Waldrop