Printing proofs are used to insure accuracy in commercial printing applications. There are different reasons to have press, digital or pdf proof. It depends upon the type of label/package and printing application you desire. Your specific product application, point of sale, and purpose will help determine the proof you use.

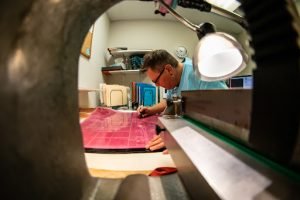

A press proof is higher quality, but more expensive because of setup time and labor. Dies are selected and image plates are loaded onto the press and printed on the material the actual job surface that will be used for the entire run. The press operator must wait upon the client to approve the proof. Once approved the operator can run the order. However, if changes are made by the client the work returns to the prepress department where new plates are run to accommodate the changes. Meanwhile the press is sitting idle and the client is paying for the down time which increases the total cost of the project. Changes at the press proof stage are costly. A big advantage of the press proof is that it is printed on the actual material of your package or label so you can gauge a point of sale look and feel from it. Press proofs are great for offering new products that need a splash at the point of sale to stand out from the competition.

A press proof is higher quality, but more expensive because of setup time and labor. Dies are selected and image plates are loaded onto the press and printed on the material the actual job surface that will be used for the entire run. The press operator must wait upon the client to approve the proof. Once approved the operator can run the order. However, if changes are made by the client the work returns to the prepress department where new plates are run to accommodate the changes. Meanwhile the press is sitting idle and the client is paying for the down time which increases the total cost of the project. Changes at the press proof stage are costly. A big advantage of the press proof is that it is printed on the actual material of your package or label so you can gauge a point of sale look and feel from it. Press proofs are great for offering new products that need a splash at the point of sale to stand out from the competition.

Digital proofs are ideal for smaller runs because the turnaround time is quicker. Digital proofs don’t require the intense setup and preparation of press proofs that require plates and dyes. The industry refers to digital proofs as GMG proofs. The digital proof is not the press so it is not made of the same material. It is a GMG laminate whereas the press proof is actual product/label surface material. Digital proofs are extremely color accurate. The digital proof is fingerprinted to the press so the color profile is very accurate. The digital proof, like the press proof, is a physical proof that has to be sent to the client, or their agent for approval. This is usually done via UPS/FedEx and upon client approval the proof returns to the press operator to use for accurate color matching.

A PDF proof is the fastest and economical way to proof a print file before going to press. The beauty of a PDF is that it can be viewed across various platforms. However, there can be many color variations on the original from the printer because of the platform, software and monitor being used to view, or print it.

If color accuracy is critical you will want more than a PDF proof. PDF’s have expedited the proof process because of their universal availability and short turn around.

Many label printing and packaging vendors produce a digital proof of all of their work for their own files and purposes. The experienced companies will be able to replicate color and design with very little down time, or change orders in regard to the proof. Customers should ask for examples/samples of various proofs the company has run for other companies with similar applications. This will provide a good picture of what this company is capable of doing and it will save the manufacturer, or customer time and money.

Ben Waldrop

Ben Waldrop

President

Century Printing & Packaging

Greer, SC 29651

800.344.7509

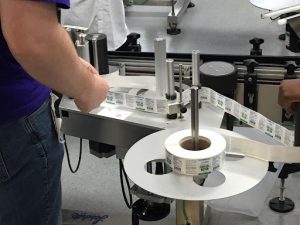

The advantage of the Digital Press is high quality in shorter numbers eliminating the process of plate setups and long runs on Lithographic presses. Detail is stunning and labels that can withstand spills from oils, wet/cold applications and more duress are not only achievable, but also possible in a relative short turn around. The digital press offers a variety of industry the opportunity for high definition, consumer appealing labels that meet or exceed a diverse range of application requirements ranging from temperature, or wet, to oil, or fold out direction, or instruction flaps.

The advantage of the Digital Press is high quality in shorter numbers eliminating the process of plate setups and long runs on Lithographic presses. Detail is stunning and labels that can withstand spills from oils, wet/cold applications and more duress are not only achievable, but also possible in a relative short turn around. The digital press offers a variety of industry the opportunity for high definition, consumer appealing labels that meet or exceed a diverse range of application requirements ranging from temperature, or wet, to oil, or fold out direction, or instruction flaps. Ben Waldrop, President

Ben Waldrop, President