Tell us how long you’ve been with Century and your background

I’ve been with Century for seven years and working in the print industry for over 30 years. I had been working for another company and they downsized so I was looking for a position when I interviewed here. Initially, I was producing artwork and had a lot of experience working with color so flexo was ideal for me.

When I started I already had an understanding about different substrates, white inks, adjusting color for flexographic printing and things like that. Getting involved in artwork helped expand my skill set. Previously we had to manually enter job numbers, ink and other materials but software and automation have enabled us to focus on the artwork.

Describe your role at Century Printing and Packaging

Describe your role at Century Printing and Packaging

I supervise the pre-press department and I initially work with the sales staff to preflight the art and help determine colors and any special concerns in printing and what we can do to maintain the aesthetics whether it is digital or flexo printing.

What’s your favorite part of relating to clients/customers?

I deal with the clients and their artists. Just being able to take their vision and reproduce it in flexo, which isn’t always very forgiving is rewarding. I often ask, “how will this go or look?” Then I huddle with Neil and Roger to see how we can help the customer. We come up with stuff that clients are not taking advantage of like silver substrates and more, or we’ve inverted the white ink and the client was thrilled. Exceeding customer expectations is really important and so professionally satisfying.

What do you still get excited about in your job?

I get a thrill any time I walk into a store and see packaging or printing that I had a hand in producing. Back in the day changes were crazy. Before everything went to the computer, we manually worked the camera, trapping and setting up the file for plating, etc. When using film we moved to less manual input and today it’s nice and neat. Technology has increased the rate of production and things that took ½ day we can now do in 10 minutes. It used to take us a long time to do one thing or concept, but now we can move faster and eliminate errors on the fly.

What do you like about Century Printing and Packaging?

What do you like about Century Printing and Packaging?

It’s a family-owned business and that family-style transcends down to all employees. We get to know each other and know our strengths and weaknesses. The last seven years it’s evolved into a team atmosphere. It’s more than a place to work and the culture of “that’s not my job” has shifted and evolved into, “how can I help you and what can I do to make this better.” When you’ve got a label that works really well from start to finish everyone has a sense of pride in the production of it, so team pride is a big thing here.

Tell us about yourself, Connie?

I am Spartanburg born and raised. I’ve been married for eight years with three children and five grandchildren. My grandmother had a tradition of cooking Sunday dinner for the entire family and I grew up doing that so when her health began to fail we ended up serving at my house and I lost my Mom and grandmother, but we’ve kept the tradition going.

How did Covid affect your work?

It changed the dynamics of our work. Newspapers had lots of cancellations all in advance. We responded really quickly to adjust with masks, safe distancing, PPE, etc. We noticed what we are printing is changing with lots of labels for industrial, chemical, food and beverage like craft beer labels. Our labels are getting more sophisticated with performing and a more pronounced look and feel.

What have you learned in your tenure?

What have you learned in your tenure?

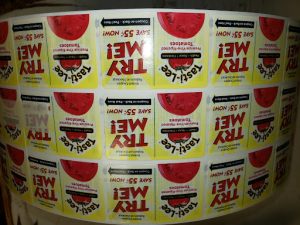

Well, grocery stores were one of the first jobs and I was fascinated by the labeling and how certain things sold better than others and how the value of packaging, aesthetics and appearance have evolved to impact branding and target audiences.

What do you do in your downtime?

I am an avid reader and an attempted novelist with a passion for Southern fiction.

At Century Printing and Packaging we have a long line of tenured employees who make up our team. We are proud of their work, spirit, and the contribution they make to our quality of work and production. All of them work hard to fulfill customers’ orders and produce high-quality work.

What do you enjoy most about working at Century Printing and Packaging?

What do you enjoy most about working at Century Printing and Packaging?

Whether unsupported film packaging or adhesive labels, every business segment is different in terms of need. I have to be familiar with their product, the market, their target while having a knowledge of our production capabilities and limitations. I never want to over-promise or under-deliver to our customers. I’ve learned a lot about the various types of substrates we can print on and our customers’ needs with regard to labels and flexible packaging. There have been so many aspects of the production process that I have learned over the years.

Whether unsupported film packaging or adhesive labels, every business segment is different in terms of need. I have to be familiar with their product, the market, their target while having a knowledge of our production capabilities and limitations. I never want to over-promise or under-deliver to our customers. I’ve learned a lot about the various types of substrates we can print on and our customers’ needs with regard to labels and flexible packaging. There have been so many aspects of the production process that I have learned over the years. What changes have you seen in the company since you started?

What changes have you seen in the company since you started? Describe the culture at CP&P and what it’s like to work there

Describe the culture at CP&P and what it’s like to work there