Businesses can’t do business without doing business! Let that one sink in for a moment. In order to produce your product or perform your services, you have to rely on multiple businesses, suppliers, and vendors to get the job done. Companies involved in manufacturing have to deal with a wide variety of vendors to make their products or goods. In today’s marketplace, the kind of relationship you have with your vendors is critical due to supply chain disruptions, logistics, and labor issues, not to mention the rate of inflation.

Businesses can’t do business without doing business! Let that one sink in for a moment. In order to produce your product or perform your services, you have to rely on multiple businesses, suppliers, and vendors to get the job done. Companies involved in manufacturing have to deal with a wide variety of vendors to make their products or goods. In today’s marketplace, the kind of relationship you have with your vendors is critical due to supply chain disruptions, logistics, and labor issues, not to mention the rate of inflation.

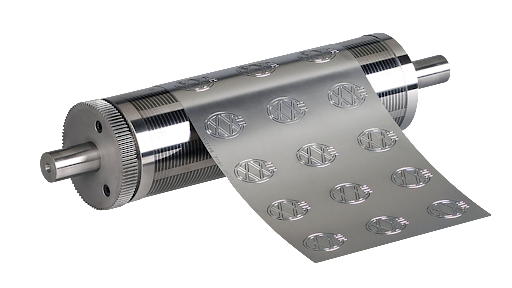

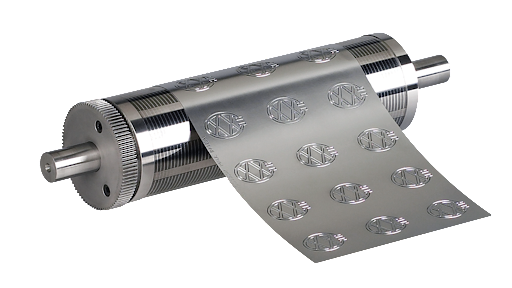

One of Century Printing and Packaging’s oldest vendors is Wilson Manufacturing. Wilson makes rotary tooling in hard, solid, and engraved dies, anvils, and print cylinders as well as flexible tooling (magnetic dies). Flexible tooling provided by Wilson is ideal for printing pressure-sensitive labels of different shapes and forms. We sat down with Kevin Harfst, Southeast Territory Sales Representative at Wilson to discuss their products, work, and relationship with Century.

Tell us about Wilson Manufacturing

Tell us about Wilson Manufacturing

Our start is similar to Century’s but we are a little older. We started in the mid-70s in a garage. Mr. Wilson had left a big company that made presses that did both printing and die-cutting. He saw the potential for more tooling and started his own company. Since those days we’ve grown into about a $20M company. Most of our growth has occurred in the last 20 years as we discovered some cutting-edge technology with machine sharpened tooling.

Why was that so important?

Once we were able to machine sharpen these dies that had historically been hand sharpened, which is exactly what it sounds like. Guys would sit around and look through a jeweler’s loop and have these dies that would sit on a jig in front of them and they sharpened the blades by hand using different types of scraping tools. Machine sharpening is much faster and the quality is second to none compared to hand sharpening.

Describe Wilson’s relationship with Century?

Describe Wilson’s relationship with Century?

Century and Wilson have been working together for at least 20+ years. Over the years they have dealt with different people at Wilson and they have been there every step of the way as we have grown and watched them grow as well. I got involved with them about five years ago as I moved from our west coast territory to the southeast region where most of my family is located. They are definitely the gold standard for customers from the point of communicating, and understanding exactly what they need and their work. The needs we are able to service for them and what they come to us for we’re able to hit that on the head 100% virtually every time. We have bigger clients, but they have been so consistent from year to year and the growth they’ve had has definitely kept them in a higher customer weight class.

What do you think about Century entering its 25th year?

The growth of Century Printing and Packaging over the past 20 years is something that we have paid close attention to and they have certainly helped us grow as well. As they have embraced and invested in cutting-edge technology so have we. They were one of the first printing companies to start doing magnetic dies and cylinders. And just recently they are the first in the U.S. to invest in a brand new hybrid printing platform.

How did Covid affect your business?

We have not been as challenged to the extent that the printing companies and label companies have been securing materials with supply chain issues and material shortages. 80% of our steel is made in the U.S. so we have not had an issue getting our raw materials, but it’s only a matter of time as the inventory of steel in the United States is predicted to come down. Covid really affected us in a different way. Because many of our customers are in different parts of the country their businesses were closed at the height of the pandemic. Now everywhere is pretty open and going.

Describe your role at Wilson

Describe your role at Wilson

Primarily sales, but I do more than quoting and order-taking because I have a technical background and I’ve been doing this since 1996. I like to get out and get into the companies that I call on to see their production and talk to their production team to go over various tricks of the trade that we can help them with to make their product run better and help their press operators feel more at ease. I also get involved with the crew that does the estimating and purchasing so they can use some of our benefits like our web services that can help them in ordering or getting information on a specific product.

What is a trend in your industry?

Adjustable anvils are big. It is tied in with the problems customers are having with getting their materials. All of these materials they run through their presses get die cut from the top, but these rolls of material go over what is called an anvil. You have a male-female setup in the die station with the die top-cutting and the anvil being the surface below that the die cuts against. What we’re seeing is that the materials have such a variation amongst the liners so by creating an adjustable anvil we can accommodate the variations in the different liners.

At Team Century you hear a lot about the importance of relationships with customers and vendors can you address that?

What Century is doing is custom printing and die-cutting. They aren’t servicing a blank label market, or a generic product where someone calls in and they have an inventory of what they need. It is total custom printing from the artwork down to the shapes they cut. By being able to build a customer-vendor relationship from the standpoint that Century and Wilson have it works out very well if you can trust each other. And know that each can take care of needs as they arise because every die that comes along on our end is different and a lot of the materials they may cut are different from time to time. They may have a dozen standard materials, but they branch into different laminates, varnishes, liners, and substrates. So having a proven relationship built on trust with someone you know is going to be able to deliver specifically what you need is critical. It’s a win-win!

Century Printing and Packaging is an ISO 9001:2015 certified company located in Greer, South Carolina. Flexographic, roll stock film, flexible packaging, digital printing, nutraceutical, food, and craft beer labels are among our extensive print products and technologies. We are family-owned and operated. Call us today about all of your printing or packaging needs. Our southeast location allows us to have a two-day shipping point via FedEx or UPS ground to 80% of the U.S population and we can expedite as necessary.

Ben Waldrop

Ben Waldrop

President

Century Printing & Packaging

Greer, SC 29651

800.344.7509

Century Printing and Packaging has been studying these industry trends and invested heavily in the future of digital printing. Our company made a major investment in digital-hybrid printing technology in order to meet the demands of our customers, improve the quality of the end product, cut down on waste for the environment and deliver stellar imaging. We invested in the Mark Andy Digital IQ Series hybrid press to give us more competitive space where digital printing is becoming a requirement. It allows us to use the flexibility of our flexographic knowledge accumulated from 25 years in addition to the new technology of inkjet to get vibrant colors with uv inks that provide a high level of consistency and durability.

Century Printing and Packaging has been studying these industry trends and invested heavily in the future of digital printing. Our company made a major investment in digital-hybrid printing technology in order to meet the demands of our customers, improve the quality of the end product, cut down on waste for the environment and deliver stellar imaging. We invested in the Mark Andy Digital IQ Series hybrid press to give us more competitive space where digital printing is becoming a requirement. It allows us to use the flexibility of our flexographic knowledge accumulated from 25 years in addition to the new technology of inkjet to get vibrant colors with uv inks that provide a high level of consistency and durability. The new technology allows us to group jobs together very easily so we can run them whether short or large for the same customer and gives us a lot of flexibility in scheduling we did not have previously. We have made a significant investment in this press to position ourselves for growth and to meet customer expectations with the highest technology possible within the industry. After four weeks of setup and a lot of manpower from Mark Andy’s staff, our press operators are feeling comfortable with the new technology. In addition to our production department needing training, our pre-press department has made this a seamless effort to deliver consistent quality and results for our clients. Both departments have worked harmoniously to produce stellar imaging and product.

The new technology allows us to group jobs together very easily so we can run them whether short or large for the same customer and gives us a lot of flexibility in scheduling we did not have previously. We have made a significant investment in this press to position ourselves for growth and to meet customer expectations with the highest technology possible within the industry. After four weeks of setup and a lot of manpower from Mark Andy’s staff, our press operators are feeling comfortable with the new technology. In addition to our production department needing training, our pre-press department has made this a seamless effort to deliver consistent quality and results for our clients. Both departments have worked harmoniously to produce stellar imaging and product.

This is cutting edge for the industry, isn’t it?

This is cutting edge for the industry, isn’t it? Ben Waldrop

Ben Waldrop

Neil, how did Century Printing and Packaging Begin?

Neil, how did Century Printing and Packaging Begin? 25 years ago did you ever think it would be on this scale?

25 years ago did you ever think it would be on this scale? The latest major change in the industry is digital printing. It has been around for about ten years, but within the last five years it has escalated in terms of speed, quality and the ability to print more substrates has allowed it to really explode, which has pros and cons. Some work can’t be done on flexo and has to be done on a digital press. Traditionally, digital has been a higher cost in long production runs but the prices are coming down which is why we are securing new equipment. To be competitive we’ve got to be able to produce the quality at the price our customers need.

The latest major change in the industry is digital printing. It has been around for about ten years, but within the last five years it has escalated in terms of speed, quality and the ability to print more substrates has allowed it to really explode, which has pros and cons. Some work can’t be done on flexo and has to be done on a digital press. Traditionally, digital has been a higher cost in long production runs but the prices are coming down which is why we are securing new equipment. To be competitive we’ve got to be able to produce the quality at the price our customers need. What are some of the things you are seeing in the future of the printing and packaging industry?

What are some of the things you are seeing in the future of the printing and packaging industry? So tell us about your family

So tell us about your family

Manufacturers are scrambling to find new supply lines and vendors. Shortages from food, chemicals, lumber, metals, microchips, rubber goods, paper, laminates, and countless other goods have moved businesses from a competitive price focus to sheer availability. Shortages and availability only tighten the vise grip of competing manufacturers. Auto manufacturers are now competing with consumer electronics for computer chips. Before the storm, each had different suppliers and there was no shortage. During the storm, you may produce cars, but your computer or television producer has landed in your backyard competing for the same chips.

Manufacturers are scrambling to find new supply lines and vendors. Shortages from food, chemicals, lumber, metals, microchips, rubber goods, paper, laminates, and countless other goods have moved businesses from a competitive price focus to sheer availability. Shortages and availability only tighten the vise grip of competing manufacturers. Auto manufacturers are now competing with consumer electronics for computer chips. Before the storm, each had different suppliers and there was no shortage. During the storm, you may produce cars, but your computer or television producer has landed in your backyard competing for the same chips. The interdependency within the global economy can best be explained by dominoes falling one over the other throughout a massive display. Everything relates to the other. Loaded ships sit in harbors and can’t get unloaded, a pandemic wiped out 700,000 people in the U.S. alone to date. Many of those were workers and paying taxes. The printing and packaging industry is experiencing supply and material increases between 7-12%, if not more. Polypropylene resin has increased 150% since January of 2020, and PET resin has risen over 20% in the same period (CDI October 2021 Report). Some Industry experts are projecting continued shortages of raw material and polymers to last through Q4 2022.

The interdependency within the global economy can best be explained by dominoes falling one over the other throughout a massive display. Everything relates to the other. Loaded ships sit in harbors and can’t get unloaded, a pandemic wiped out 700,000 people in the U.S. alone to date. Many of those were workers and paying taxes. The printing and packaging industry is experiencing supply and material increases between 7-12%, if not more. Polypropylene resin has increased 150% since January of 2020, and PET resin has risen over 20% in the same period (CDI October 2021 Report). Some Industry experts are projecting continued shortages of raw material and polymers to last through Q4 2022. No reputable and successful business enjoys price increases. Their success is built upon providing a high-quality product/service at a competitive price backed with extraordinary customer service. These companies thrive on long-term customer relationships by exceeding customer expectations. However, there is a point at which even the strongest cannot resist anymore because they start losing money.

No reputable and successful business enjoys price increases. Their success is built upon providing a high-quality product/service at a competitive price backed with extraordinary customer service. These companies thrive on long-term customer relationships by exceeding customer expectations. However, there is a point at which even the strongest cannot resist anymore because they start losing money. Smart companies and businesses are concentrating on minimizing price increases while extending their vendor partnerships to have access to the materials and supplies they need to do their jobs. Increased costs are inevitable given the global market, but smart and reputable suppliers and manufacturers are working with their clients and suppliers to keep prices as low as they can. Material and supply shortages can be expected well into 2022. Plan way ahead to get ahead of this troubling trend. Hopefully, supply, logistics, and labor will self-correct in 2022.

Smart companies and businesses are concentrating on minimizing price increases while extending their vendor partnerships to have access to the materials and supplies they need to do their jobs. Increased costs are inevitable given the global market, but smart and reputable suppliers and manufacturers are working with their clients and suppliers to keep prices as low as they can. Material and supply shortages can be expected well into 2022. Plan way ahead to get ahead of this troubling trend. Hopefully, supply, logistics, and labor will self-correct in 2022.