Neil, Chief Operating Officer at Century Printing and Packaging, has a side hustle that combines passion with purpose: beekeeping. At a time when the honey bee ecosystem is in decline, Neil is doing his part to help save these essential pollinators. With the guidance of experienced beekeepers and by mentoring others, Neil’s hobby has become a way to do his part in positively impacting the environment.

Neil’s journey into beekeeping started as a family tradition, deeply rooted in his father’s lifelong passion for the craft. His dad, now 78, has been involved with beekeeping in some capacity since he was 12 years old. After retiring, Neil’s father revived his interest, setting up a few hives in his backyard. However, the space proved inadequate as the hives flourished. Neil’s dad brought some hives to the Century Printing and Packaging office to accommodate the growing need for more space.

Neil’s curiosity was piqued as he watched his father manage the bees. What began as casual observation quickly evolved into a fervent interest. “I thought it looked like fun, so I decided to poke around and see what he was doing,” Neil recalls. “Once I got out there, I got hooked.” This newfound hobby allowed Neil to bond with his father and ignited a deep passion for beekeeping, leading to an enriching and ongoing family endeavor.

Neil’s curiosity was piqued as he watched his father manage the bees. What began as casual observation quickly evolved into a fervent interest. “I thought it looked like fun, so I decided to poke around and see what he was doing,” Neil recalls. “Once I got out there, I got hooked.” This newfound hobby allowed Neil to bond with his father and ignited a deep passion for beekeeping, leading to an enriching and ongoing family endeavor.

For anyone unfamiliar with the foundations of beekeeping, regular inspections are crucial for maintaining the health and productivity of a beehive. Neil conducts inspections every 5-7 days during the peak season to ensure everything is in order. He checks the queen’s presence and the brood pattern (the eggs, larvae, and pupae that will eventually populate the hive), ensuring the queen properly lays eggs. Assessing honey and pollen stores is another vital task, as it ensures the bees have enough food. Neil provides adequate space for the colony to expand in spring and summer and reduces hive size in fall to help the bees keep the brood warm.

A hive can rapidly transition from healthy to unhealthy in as little as two weeks. Neil stays vigilant for signs of trouble, such as decreased activity, unusual brood patterns, or erratic and aggressive behavior. Common issues include natural predators like Japanese hornets and bears, Varroa mites, and diseases like American foulbrood. When an affected hive is found, Neil quickly diagnoses and treats it accordingly. As part of Neil’s hive health protocol, all queens are replaced annually with a natural requeening process when the current queen fails.

A honey bee colony is a well-organized community with specific roles. The queen lays eggs and emits pheromones to regulate the hive. Forager bees gather nectar, pollen, and water, build comb, and guard and clean the hive. Drones mate with the queen and are expelled in the fall to conserve resources. Nurse bees care for the brood, while scouts find resources outside the hive and communicate with the forager bees about where to go for resources. These roles are crucial for the colony’s survival and productivity.

Neil’s hives have several essential parts, each serving a specific function. The bottom board prevents moisture and pests. The entrance reducer regulates the hive entrance size. Hive bodies, or brood boxes, are deep boxes where bees raise brood and store pollen and honey. Frames with foundation hold beeswax sheets where bees build comb. Supers are used to construct excess honey and are removed from the hive to extract honey from. A full super will weigh up to 20 pounds and can produce 2-2.5 gallons of honey. The inner cover provides insulation and ventilation, while the outer cover protects the hive from the elements. Finally, the hive stand elevates the hive to prevent moisture buildup and make it easier for the beekeeper to work in it.

Caring for honey bee hives is a year-round commitment, aligning with the seasonal needs of the bees. In spring, Neil inspects hives, feeds sugar syrup if needed, assesses the queen, prevents swarming, and expands the hive. During summer, he manages hive space, monitors for pests and diseases, harvests honey, and provides a water source for the bees. Fall involves preparing the hive for winter, treating for the prevention of Varroa mites, supplementing feeding if necessary, and ensuring a healthy queen is present. In winter, Neil monitors hive weight, protects the hive from cold, and provides emergency feed if needed.

Caring for honey bee hives is a year-round commitment, aligning with the seasonal needs of the bees. In spring, Neil inspects hives, feeds sugar syrup if needed, assesses the queen, prevents swarming, and expands the hive. During summer, he manages hive space, monitors for pests and diseases, harvests honey, and provides a water source for the bees. Fall involves preparing the hive for winter, treating for the prevention of Varroa mites, supplementing feeding if necessary, and ensuring a healthy queen is present. In winter, Neil monitors hive weight, protects the hive from cold, and provides emergency feed if needed.

Neil’s dedication to beekeeping extends beyond the hives he keeps at the office. He mentors other aspiring beekeepers, sharing his knowledge and experience to help them succeed. In addition to his environmental contributions, Neil sells his honey by word of mouth to the local community, fostering a connection between his beekeeping efforts and the people around him.

His approach to selling honey is rooted in simplicity and community trust. “We just take the money and put it right back in the supplies,” Neil says, highlighting that their goal is to break even rather than make a profit. Selling the honey is a straightforward, community-centered process. Neil posts about the honey on Facebook within the neighborhood and places a sign outside the office advertising “local honey.” People can come by, take what they need, and leave money in an envelope. This trust system has worked remarkably well, with some customers buying in bulk.

The key to the honey’s popularity is its purity. Neil and his father capture, strain, and bottle the honey without heating it, which preserves its natural enzymes and proteins. This method contrasts with more extensive operations that often heat honey to speed up the process, which can diminish its beneficial properties. Neil explains, “Speed is not of the essence for me, but because we don’t heat it, we don’t kill the enzymes. It keeps all the proteins, enzymes, and other things in the honey pure.” This unprocessed honey is particularly beneficial for local allergies, and many parents in the community buy it for their children.

Honey has an extraordinary shelf-life and contains natural preservatives such as low water content and an acidic pH, creating an inhospitable environment for bacteria and microorganisms. This means it is one of the few foods that can last indefinitely without refrigeration or special storage conditions. Archaeologists have even discovered pots of honey that remain edible in ancient Egyptian tombs, thousands of years old. This unique characteristic highlights the value of honey as a nutritious food and a natural preservative. Its longevity and natural purity make honey an exceptional and fascinating substance cherished throughout history and cultures.

Neil’s side hustle in beekeeping is more than a hobby; it contributes to environmental conservation. By maintaining healthy hives, mentoring others, and staying informed about best practices, Neil is playing a significant role in addressing the decline of honey bees. His work exemplifies how individual efforts can make a meaningful difference in preserving our natural world.

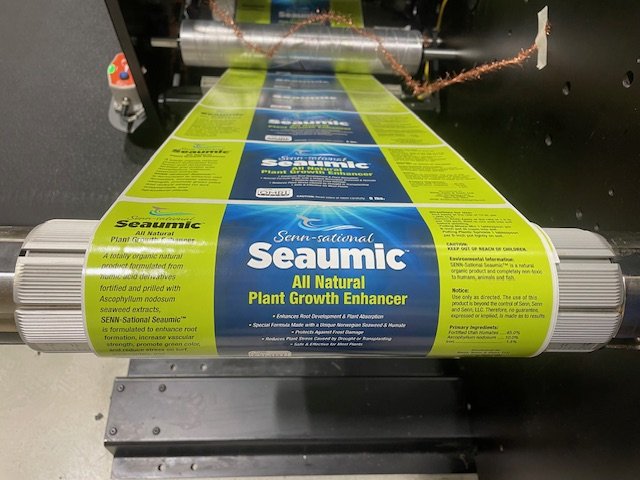

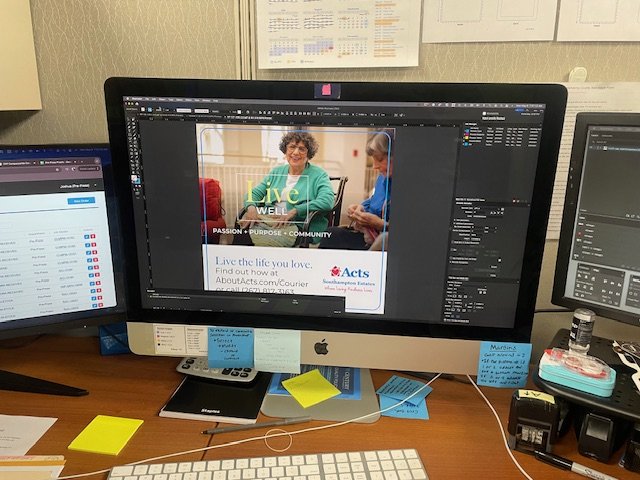

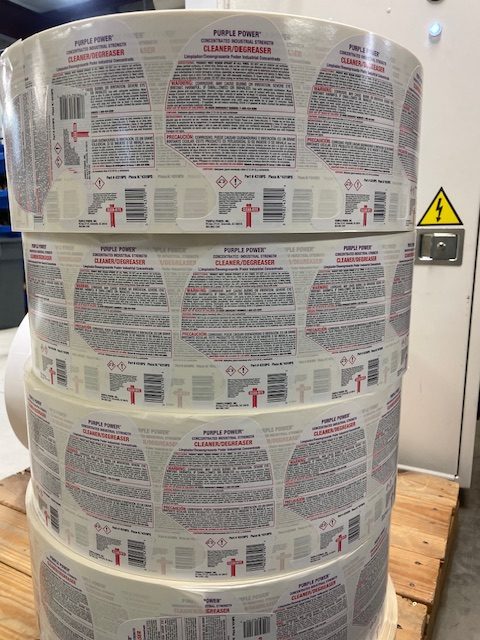

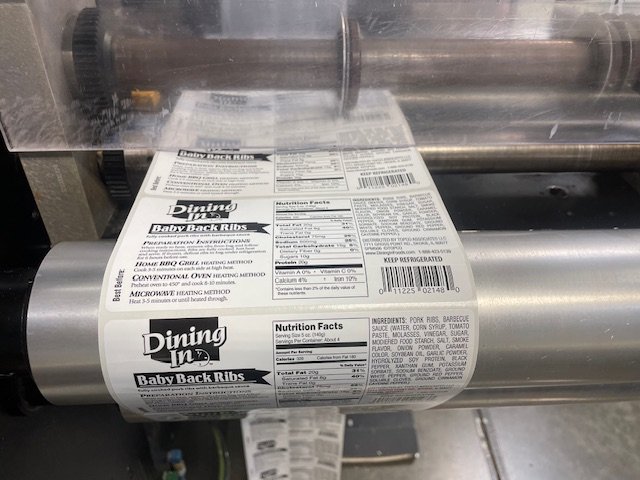

At every pre-press stage, optimization for the best outcome is key. Preparing the artwork starts with the label design for flexo printing. This involves carefully selecting appropriate colors, defining trapping and overprinting settings (which refer to the techniques used to prevent gaps or overlaps between adjacent colors in a print), using printable fonts and point size, and setting up dieline and bleed specifications. A dieline is a graphic element that serves as a template or guide to create a die, which is then used to cut or shape the label substrate.

At every pre-press stage, optimization for the best outcome is key. Preparing the artwork starts with the label design for flexo printing. This involves carefully selecting appropriate colors, defining trapping and overprinting settings (which refer to the techniques used to prevent gaps or overlaps between adjacent colors in a print), using printable fonts and point size, and setting up dieline and bleed specifications. A dieline is a graphic element that serves as a template or guide to create a die, which is then used to cut or shape the label substrate. After the prepress steps have been performed, the next order of business is setting up the press. This stage involves choosing the appropriate label substrate based on the application requirements and selecting ink formulations compatible with the preferred substrate. These first steps ensure that the substrate is clean, free from dust or debris, and properly conditioned to minimize static electricity. Ink viscosity adjustments are also conducted to achieve optimal ink transfer and color density to meet desired color specifications.

After the prepress steps have been performed, the next order of business is setting up the press. This stage involves choosing the appropriate label substrate based on the application requirements and selecting ink formulations compatible with the preferred substrate. These first steps ensure that the substrate is clean, free from dust or debris, and properly conditioned to minimize static electricity. Ink viscosity adjustments are also conducted to achieve optimal ink transfer and color density to meet desired color specifications. Next, the press setup agenda involves carefully mounting the flexographic plates onto the printing cylinders to ensure proper alignment with the cutting die. Once the plates are firmly secured using tapes or adhesive materials, it’s time to choose the appropriate anilox rolls based on the desired ink coverage and resolution requirements. Fine-tuning the printing pressure settings to achieve optimal contact between the plates, anilox rolls, and substrate is a prerequisite to avoiding excessive pressure, which can lead to plate distortion, wrong color, or substrate deformation.

Next, the press setup agenda involves carefully mounting the flexographic plates onto the printing cylinders to ensure proper alignment with the cutting die. Once the plates are firmly secured using tapes or adhesive materials, it’s time to choose the appropriate anilox rolls based on the desired ink coverage and resolution requirements. Fine-tuning the printing pressure settings to achieve optimal contact between the plates, anilox rolls, and substrate is a prerequisite to avoiding excessive pressure, which can lead to plate distortion, wrong color, or substrate deformation. Post-press setup is just as important as the prepress and press setup stages. Regular maintenance tasks, such as cleaning ink chambers, doctor blades, and anilox rolls, prevent ink buildup and maintain printing consistency. Replacing worn-out or damaged components as needed is a proactive measure to avoid production disruptions. By performing these tasks regularly, you can keep your equipment in top shape, extend its lifespan, and maximize its performance for each label job.

Post-press setup is just as important as the prepress and press setup stages. Regular maintenance tasks, such as cleaning ink chambers, doctor blades, and anilox rolls, prevent ink buildup and maintain printing consistency. Replacing worn-out or damaged components as needed is a proactive measure to avoid production disruptions. By performing these tasks regularly, you can keep your equipment in top shape, extend its lifespan, and maximize its performance for each label job.