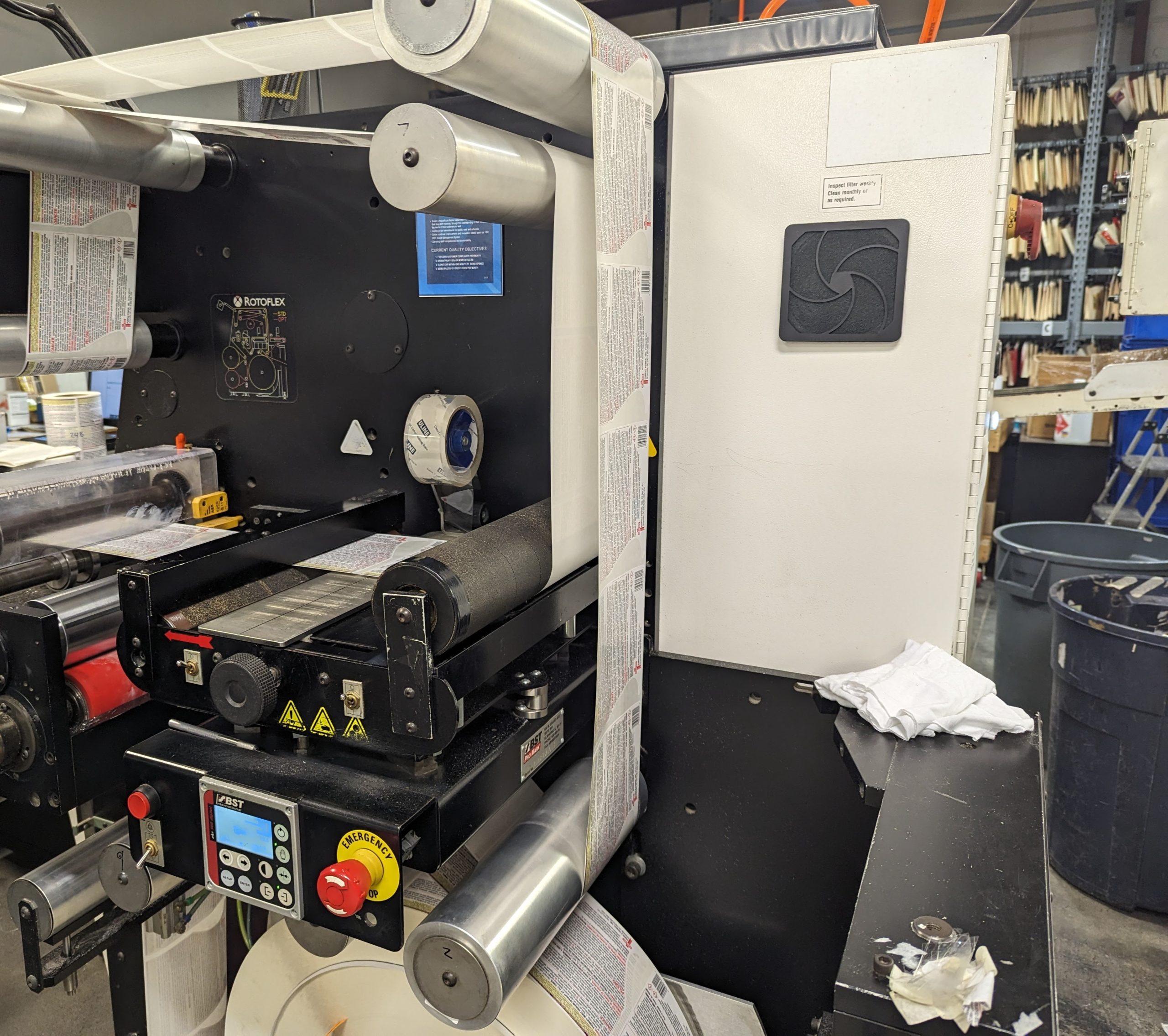

When it comes to printing, the focus often lies on the press and the creation of the label. However, the finishing responsibilities after printing are just as crucial. At Century Printing and Packaging, finishing is not just a step; it’s an art that ensures your labels are printed beautifully and ready for use.

Finishing is the final stage between printing and shipping. It involves several key processes that transform the printed material into the final product ready for application. After printing, the labels are rewound to the desired size rolls using standup or tabletop rewinders. Standup rewinders are faster and used for larger jobs, while tabletop rewinders are ideal for smaller jobs or those requiring splicing. The labels are also slit if necessary, dividing a single roll into multiple rolls.

Splicing ensures that labels are seamlessly joined together, whether applied by hand or machine. When labels are machine-applied, the splice must be stronger to withstand the tension from the applicator. In contrast, labels applied by hand require a less intense splice. Understanding how the label will be applied is essential for determining the type of splice needed. This attention to detail ensures that labels are prepared correctly for their intended use, highlighting Century’s commitment to delivering high-quality products tailored to their customers’ needs.

Splicing ensures that labels are seamlessly joined together, whether applied by hand or machine. When labels are machine-applied, the splice must be stronger to withstand the tension from the applicator. In contrast, labels applied by hand require a less intense splice. Understanding how the label will be applied is essential for determining the type of splice needed. This attention to detail ensures that labels are prepared correctly for their intended use, highlighting Century’s commitment to delivering high-quality products tailored to their customers’ needs.

There are three main packaging options that can be chosen for different reasons: rolled, fan-folded, or sheeted. Rolled labels are the most common, with the material received on rolls, printed, and then finished on rolls. Fan folding is used for applications like newspapers, where labels are folded together. Sheeted labels are individual sheets that must be stacked, counted, and organized.

Meticulous quality control measures are in place throughout the process to ensure the labels meet specifications and match the customer’s proof. Once everything is set up and approved, the operator proceeds with the finishing process, which may involve rewinding the labels onto smaller rolls, fan folding them, or preparing them in sheets, depending on the customer’s needs. Finally, once the labels are processed and checked, they are ready for packaging and shipping, marking the completion of the finishing process.

Finishing is a vital step in the label printing process that can often get overlooked. However, it’s the final touch that guarantees your labels not only look great but are also ready to be used as intended. At Century Printing and Packaging, each member of the finishing department understands the nuances of this final stage, ensuring even the most complex jobs are handled with precision. The customer’s proof serves as a reference point throughout the process, ensuring that the finished labels match the customer’s specifications. This attention to detail prevents errors and saves time and resources by catching any issues early in the process. By prioritizing quality control and proofs, Century Printing and Packaging demonstrates its commitment to delivering superior results with enhanced appeal for every label.

Finishing is a vital step in the label printing process that can often get overlooked. However, it’s the final touch that guarantees your labels not only look great but are also ready to be used as intended. At Century Printing and Packaging, each member of the finishing department understands the nuances of this final stage, ensuring even the most complex jobs are handled with precision. The customer’s proof serves as a reference point throughout the process, ensuring that the finished labels match the customer’s specifications. This attention to detail prevents errors and saves time and resources by catching any issues early in the process. By prioritizing quality control and proofs, Century Printing and Packaging demonstrates its commitment to delivering superior results with enhanced appeal for every label.

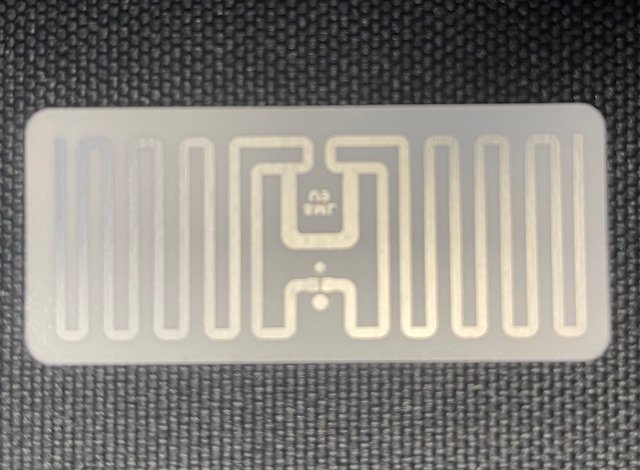

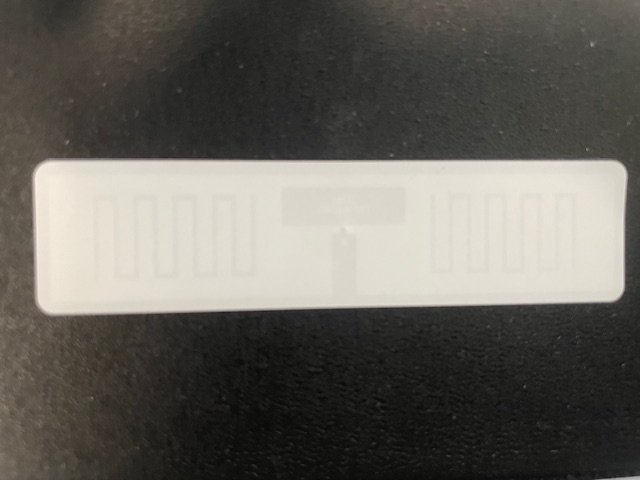

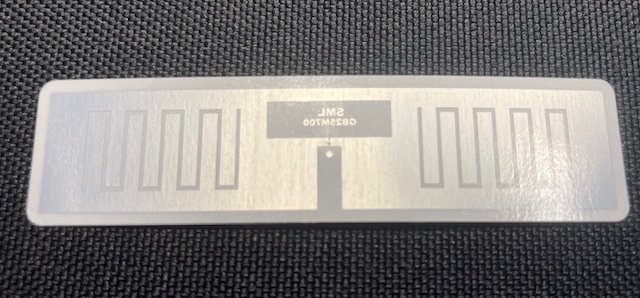

RFID, which stands for Radio Frequency Identification, is a revolutionary technology that provides real-time visibility into inventory levels, making restocking shelves more streamlined and accurate. With RFID, each product or package is equipped with a tag containing an antenna, a transceiver, and a transponder. Employees can quickly scan products with handheld devices or, eventually, through automated systems like robots that constantly take inventory. This instant feedback ensures that items are always in stock, preventing customer frustration and loss of sales.

RFID, which stands for Radio Frequency Identification, is a revolutionary technology that provides real-time visibility into inventory levels, making restocking shelves more streamlined and accurate. With RFID, each product or package is equipped with a tag containing an antenna, a transceiver, and a transponder. Employees can quickly scan products with handheld devices or, eventually, through automated systems like robots that constantly take inventory. This instant feedback ensures that items are always in stock, preventing customer frustration and loss of sales. Finally, the label is applied to the product during the third step. Care and attention to detail are crucial during this process, as any damage to the label or its components can render it useless. For suppliers sending products to retailers like Walmart, damaged RFID labels can lead to rejection and lost business.

Finally, the label is applied to the product during the third step. Care and attention to detail are crucial during this process, as any damage to the label or its components can render it useless. For suppliers sending products to retailers like Walmart, damaged RFID labels can lead to rejection and lost business.

Price

Price

One major factor that has affected the beer industry is the shortage of glass. Coming out of the pandemic, supply chain issues have resulted in many beer brands opting to purchase unprinted cans and add their own labels as needed. This not only offers more flexibility in terms of branding and design, but it also allows breweries to save money by only ordering the exact amount of cans they need at any given time.

One major factor that has affected the beer industry is the shortage of glass. Coming out of the pandemic, supply chain issues have resulted in many beer brands opting to purchase unprinted cans and add their own labels as needed. This not only offers more flexibility in terms of branding and design, but it also allows breweries to save money by only ordering the exact amount of cans they need at any given time.

Manufacturers are scrambling to find new supply lines and vendors. Shortages from food, chemicals, lumber, metals, microchips, rubber goods, paper, laminates, and countless other goods have moved businesses from a competitive price focus to sheer availability. Shortages and availability only tighten the vise grip of competing manufacturers. Auto manufacturers are now competing with consumer electronics for computer chips. Before the storm, each had different suppliers and there was no shortage. During the storm, you may produce cars, but your computer or television producer has landed in your backyard competing for the same chips.

Manufacturers are scrambling to find new supply lines and vendors. Shortages from food, chemicals, lumber, metals, microchips, rubber goods, paper, laminates, and countless other goods have moved businesses from a competitive price focus to sheer availability. Shortages and availability only tighten the vise grip of competing manufacturers. Auto manufacturers are now competing with consumer electronics for computer chips. Before the storm, each had different suppliers and there was no shortage. During the storm, you may produce cars, but your computer or television producer has landed in your backyard competing for the same chips. The interdependency within the global economy can best be explained by dominoes falling one over the other throughout a massive display. Everything relates to the other. Loaded ships sit in harbors and can’t get unloaded, a pandemic wiped out 700,000 people in the U.S. alone to date. Many of those were workers and paying taxes. The printing and packaging industry is experiencing supply and material increases between 7-12%, if not more. Polypropylene resin has increased 150% since January of 2020, and PET resin has risen over 20% in the same period (CDI October 2021 Report). Some Industry experts are projecting continued shortages of raw material and polymers to last through Q4 2022.

The interdependency within the global economy can best be explained by dominoes falling one over the other throughout a massive display. Everything relates to the other. Loaded ships sit in harbors and can’t get unloaded, a pandemic wiped out 700,000 people in the U.S. alone to date. Many of those were workers and paying taxes. The printing and packaging industry is experiencing supply and material increases between 7-12%, if not more. Polypropylene resin has increased 150% since January of 2020, and PET resin has risen over 20% in the same period (CDI October 2021 Report). Some Industry experts are projecting continued shortages of raw material and polymers to last through Q4 2022. No reputable and successful business enjoys price increases. Their success is built upon providing a high-quality product/service at a competitive price backed with extraordinary customer service. These companies thrive on long-term customer relationships by exceeding customer expectations. However, there is a point at which even the strongest cannot resist anymore because they start losing money.

No reputable and successful business enjoys price increases. Their success is built upon providing a high-quality product/service at a competitive price backed with extraordinary customer service. These companies thrive on long-term customer relationships by exceeding customer expectations. However, there is a point at which even the strongest cannot resist anymore because they start losing money. Smart companies and businesses are concentrating on minimizing price increases while extending their vendor partnerships to have access to the materials and supplies they need to do their jobs. Increased costs are inevitable given the global market, but smart and reputable suppliers and manufacturers are working with their clients and suppliers to keep prices as low as they can. Material and supply shortages can be expected well into 2022. Plan way ahead to get ahead of this troubling trend. Hopefully, supply, logistics, and labor will self-correct in 2022.

Smart companies and businesses are concentrating on minimizing price increases while extending their vendor partnerships to have access to the materials and supplies they need to do their jobs. Increased costs are inevitable given the global market, but smart and reputable suppliers and manufacturers are working with their clients and suppliers to keep prices as low as they can. Material and supply shortages can be expected well into 2022. Plan way ahead to get ahead of this troubling trend. Hopefully, supply, logistics, and labor will self-correct in 2022. Ben Waldrop, President

Ben Waldrop, President