One of the most important considerations for product labeling is the finish. There are many options within the printing process that need to be considered for your product or brand. Product label finishes depend on the target audience. Is your product B2B or B2C? Is it within a highly competitive retail or wholesale market? Is it a “tried and true” iconic brand, or is it a new product launch? All of these are important considerations when it comes to settling on a label finish for the product.

The two dominant finishes are matte and glossy. One is shiny, vibrant and the other is muted. Both of them provide value depending upon the specific product label, market, and target audience. However, you can add varnishes to each finish to get a very distinct look. Retail shelf appeal is so important today. Your product may be getting lost in the eye-candy game simply because of the finish of your label. If you have a new product for the market the finish selection is critical so your product will stand out against the competition at retail locations.

The material printers use (film/paper) can be semi-gloss, high gloss, or matte, but varnishes can add a distinctive look and set your product apart from the competition. Depending on the product category you will want to make sure you have the right “look and feel” for your product. Glossy is vibrant, but if the competition is all glossy you could choose a matte finish to stand out from the crowd. Let’s face it, standing out from the competition is paramount in reaching consumers in today’s market.

Reputable printers and packaging companies want to provide exactly what their customers want, but they are also subject matter experts in printing, finishes, and the look and feel of specific products. Relying on your printer’s input is invaluable. And don’t overlook the advantage of test runs to consider a variety of finish options for your product. This is an area where you want to get it right the first time and if that means running test options ahead of your final decision you are making the right call. These professional printers want to exceed customer expectations, but in order to do so, they need to explore options for each customer.

Reputable printers and packaging companies want to provide exactly what their customers want, but they are also subject matter experts in printing, finishes, and the look and feel of specific products. Relying on your printer’s input is invaluable. And don’t overlook the advantage of test runs to consider a variety of finish options for your product. This is an area where you want to get it right the first time and if that means running test options ahead of your final decision you are making the right call. These professional printers want to exceed customer expectations, but in order to do so, they need to explore options for each customer.

Your printer can add a varnish or laminate to the surface to change the look, feel, and texture of the product. In several product categories the competition is all glossy and having a matte finish makes the product stand out on the shelf.

Retro finishes are having a lot of success in the marketplace. Why? Because they stand out from the crowd. It’s a different look and feel. In competitive markets, many customers go for a glossy look. With varnishes, you can mix and match. You can have a part gloss and part matte finish using two different types of varnish. You can’t do this with a laminate finish because it has to cover the entire label surface.

Choosing a finish for your product label and packaging is incredibly important in today’s competitive marketplace. Your printing vendor should be more than able and willing to provide a variety of options. Focus groups are a great way to gain insight into product finishes in terms of look, feel, and attraction. Over the years many great products have died an early death due to finish failure and a lack of shelf appeal to the consumer. Having multiple options through test runs is a great way to gain insight into potential consumer reactions to a new product. If the competition is going all glossy in their finishes, consider a very distinct matte finish to pop your product on the shelf.

Choosing a finish for your product label and packaging is incredibly important in today’s competitive marketplace. Your printing vendor should be more than able and willing to provide a variety of options. Focus groups are a great way to gain insight into product finishes in terms of look, feel, and attraction. Over the years many great products have died an early death due to finish failure and a lack of shelf appeal to the consumer. Having multiple options through test runs is a great way to gain insight into potential consumer reactions to a new product. If the competition is going all glossy in their finishes, consider a very distinct matte finish to pop your product on the shelf.

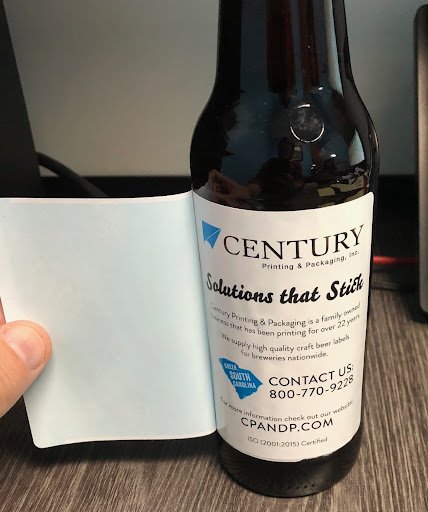

For example, today’s craft beer market is incredibly competitive. Being seen from the variety of choices available has never been greater. Having high-performing packaging and labels is critical to retail appeal. There is a greater appeal today for matte finishes versus gloss but it depends on the product market and the competition.

If you are shopping or looking for a printer ask them to provide examples in similar product categories of their work. Spend the time in graphic design and artwork to explore multiple options. Get feedback from focal groups, your team, and as many people as possible before you make a final decision. Listen to your printing and packaging company! They have years of experience in producing labels, finishes, and packaging. You are the subject matter expert of your specific product, but they are subject matter experts in the final finish of your product label and packaging. The bottom line in your final retail or wholesale product presentation is that your finish matters!

At Century Printing & Packaging we have been printing labels that stick, but have great eye appeal and consistently tell your brand story. We don’t mind tackling a challenging problem if it means we can help you produce something that is more appealing and of higher quality. We have produced labels and packaging for 25 years, so trust us to work with you as a partner instead of a job number.

Ben Waldrop, President

Ben Waldrop, President

Century Printing & Packaging

Greer, SC

Tel: 800.344.7509

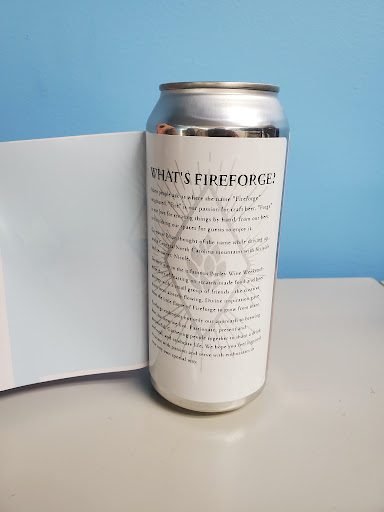

Building a loyal following begins with consistency, taste, flavor, and appeal. But if a consumer has never tried your brew it’s hard to capture all of that on six-pack printing, or a beer label until now. Traditional beer labels typically are identified by their logo, a positioning statement, or tag line and color. Beyond that there just isn’t a lot of space to expand on your brand.

Building a loyal following begins with consistency, taste, flavor, and appeal. But if a consumer has never tried your brew it’s hard to capture all of that on six-pack printing, or a beer label until now. Traditional beer labels typically are identified by their logo, a positioning statement, or tag line and color. Beyond that there just isn’t a lot of space to expand on your brand.