Flexo Label Advantage Group (FLAG) is an annual meeting for label printers across the country. This year, the event was held from June 11 to 13 in Buffalo, NY. The conference featured a diverse lineup of industry experts, thought leaders, and panel discussions covering various topics relevant to the label industry as a whole.

Century Printing and Packaging had the opportunity to engage in in-depth conversations about emerging trends, innovative technologies, sustainability practices, and best business strategies in the label printing sector. As members for the past three years, Ben and Neil value the opportunity to participate in this event, which provides a platform for uncovering new best practices, networking with peers and vendors, and gaining insights into the industry’s future.

Century Printing and Packaging had the opportunity to engage in in-depth conversations about emerging trends, innovative technologies, sustainability practices, and best business strategies in the label printing sector. As members for the past three years, Ben and Neil value the opportunity to participate in this event, which provides a platform for uncovering new best practices, networking with peers and vendors, and gaining insights into the industry’s future.

One of the most valuable aspects of being a member of FLAG is the peer group that Ben and Neil belong to. They meet virtually once a month to discuss business challenges and opportunities, but the annual meeting allows them to engage in person. This year, the collective group spent over four hours sharing insights on industry trends, sales strategies, vendor relationships, and long-term goals. These discussions are crucial for staying competitive and responsive to the shifting market.

One of the most valuable aspects of being a member of FLAG is the peer group that Ben and Neil belong to. They meet virtually once a month to discuss business challenges and opportunities, but the annual meeting allows them to engage in person. This year, the collective group spent over four hours sharing insights on industry trends, sales strategies, vendor relationships, and long-term goals. These discussions are crucial for staying competitive and responsive to the shifting market.

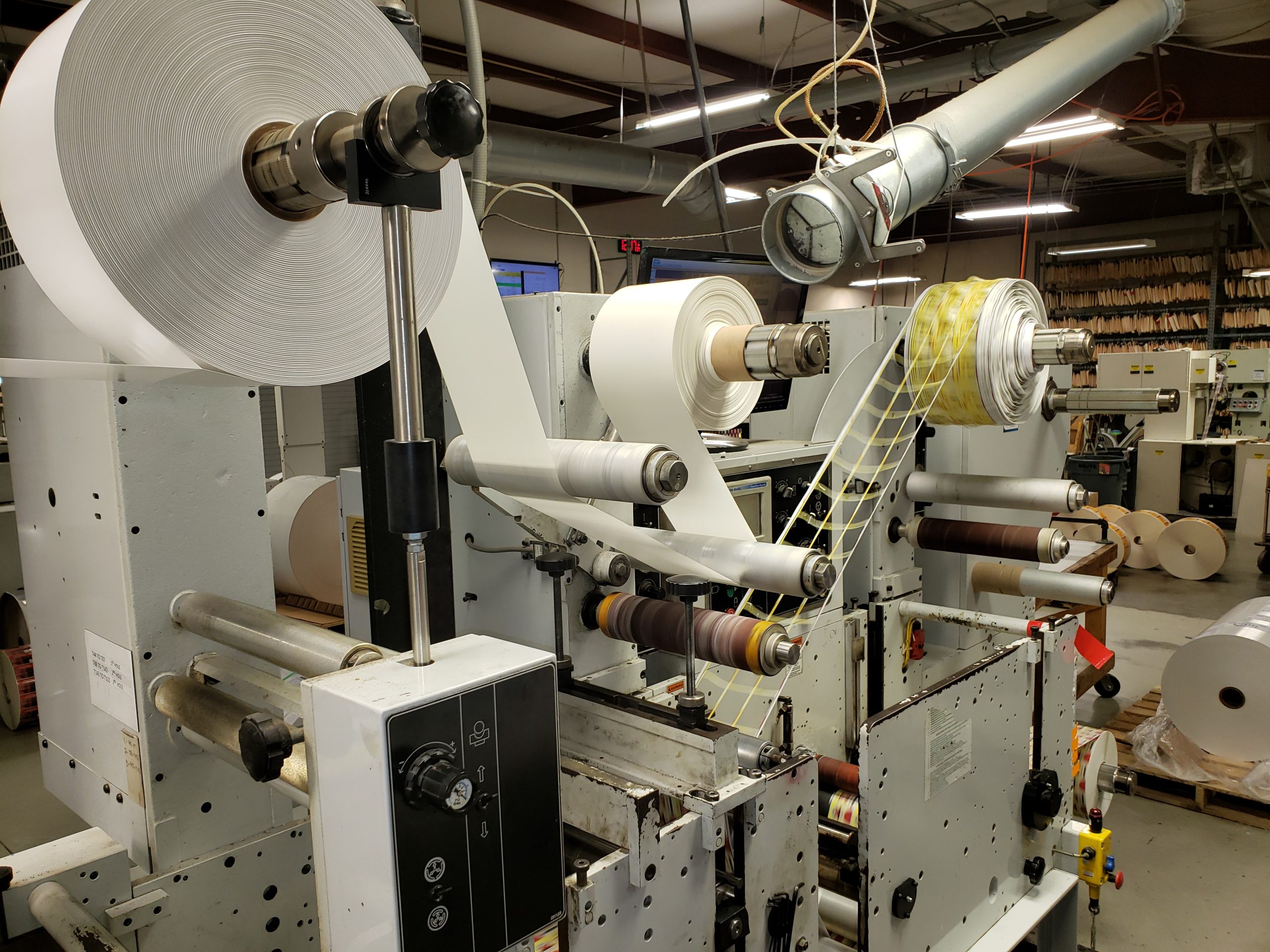

Though a smaller conference compared to others, FLAG hosted 114 attendees from various parts of the United States, providing a diverse and comprehensive networking opportunity. Meeting vendors and peers from different regions help CP&P expand its resource base and supply chain, ensuring a wide network to support all operations. As part of the event, Ben and Neil also toured a local label printer’s facility, learning about their best practices and engaging with their team. This hands-on experience provided practical insights and real-life applications.

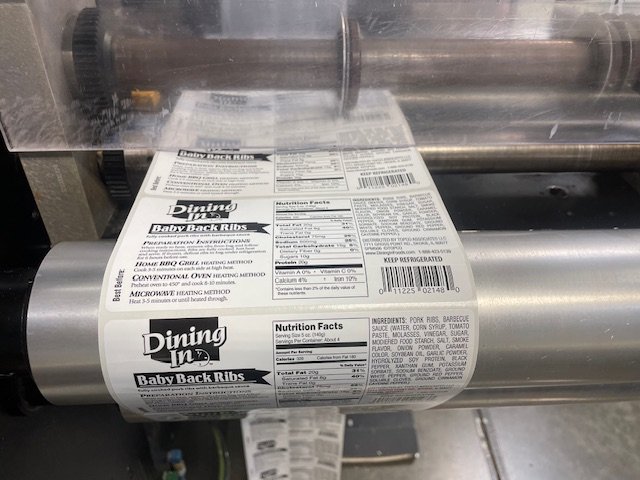

Another impactful takeaway from FLAG was the numerous opportunities for Ben and Neil to speak with other label companies that use digital presses. Century Printing and Packaging is working on adding an additional digital press to its lineup, so being able to ask questions and weigh options was invaluable for making informed decisions in the future. As CP&P evaluates the digital printing options available, their primary goal is to identify the most efficient solutions that will allow the team to deliver top-quality products to customers at the most competitive prices.

Another impactful takeaway from FLAG was the numerous opportunities for Ben and Neil to speak with other label companies that use digital presses. Century Printing and Packaging is working on adding an additional digital press to its lineup, so being able to ask questions and weigh options was invaluable for making informed decisions in the future. As CP&P evaluates the digital printing options available, their primary goal is to identify the most efficient solutions that will allow the team to deliver top-quality products to customers at the most competitive prices.

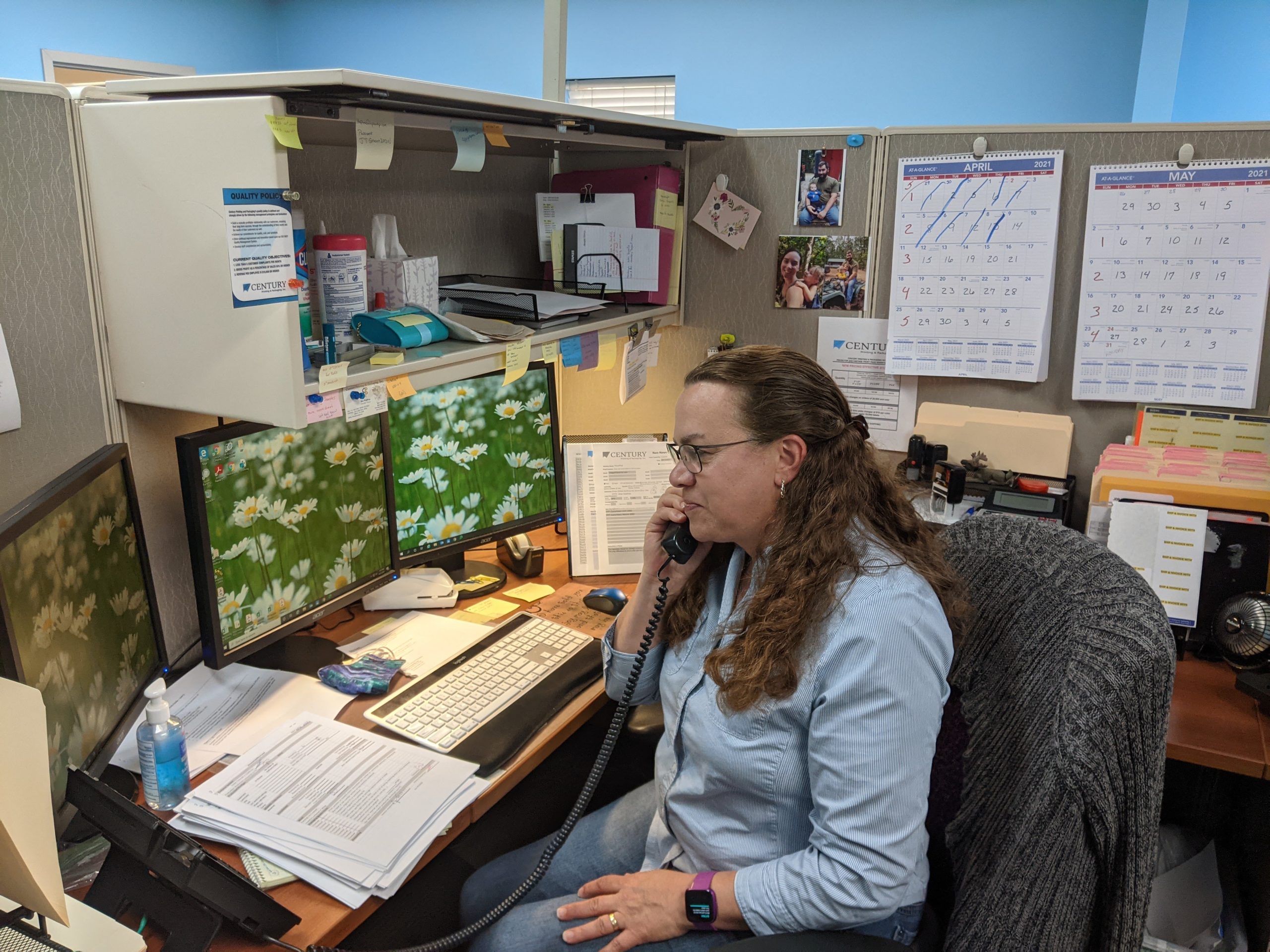

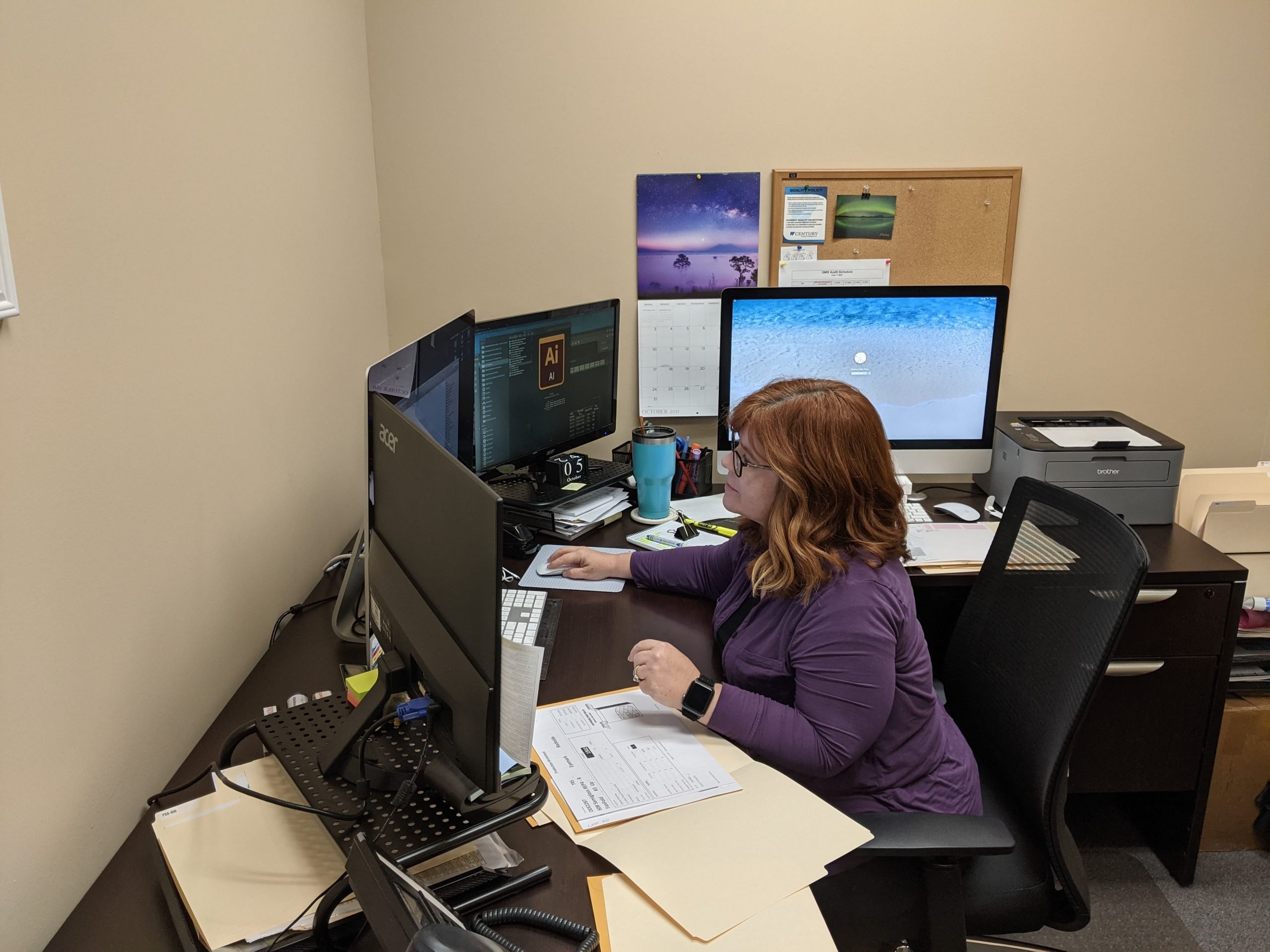

A highlight of the meeting was a talk by David Arvin, a distinguished Customer Experience and Business speaker who recently published a book on delivering world-class customer service—no matter the company’s size. His insights into what customers in today’s market expect were enlightening, which has already sparked and inspired internal conversations around how to further deepen and improve current processes around customer experience from beginning to end.

After returning from FLAG, some evident trends in the label manufacturing industry were worth mentioning—from flexible packaging to digital printing to automation and AI. The demand for flexible packaging is rapidly increasing due to its versatility and convenience. This packaging style offers numerous benefits, including the ability to conform to different shapes and sizes, lightweight nature, ease of storage, and low environmental footprint. Flexible packaging is also known for extending product shelf life and reducing transportation costs, making it a popular choice.

As digital printing’s growth continues to rise, staying modern and relevant will be pivotal. While flexographic printing remains crucial for high-volume, high-quality labels, digital printing offers indispensable versatility that has become hard to replace.

As digital printing’s growth continues to rise, staying modern and relevant will be pivotal. While flexographic printing remains crucial for high-volume, high-quality labels, digital printing offers indispensable versatility that has become hard to replace.

Automation is also a key focus in 2024, with advancements in front-end customer service and back-end production processes. Integrating software for order tracking, utilizing cobots and robots, and streamlining operations are all steps toward enhancing productivity without eliminating jobs. Lastly, integrating AI into manufacturing is no longer a distant concept. It is becoming increasingly relevant, offering ways to innovate and improve operational efficiency.

Attending the FLAG annual meeting reinforces Century Printing and Packaging’s commitment to excellence in labeling. By exchanging best practices, networking, and staying ahead of industry trends, CP&P is better equipped to serve clients in the current competitive landscape.

Material selection is critical, where a delicate balance between value and quality must be struck. Clients often seek materials that are both cost-effective and durable. CP&P has demonstrated exceptional proficiency in identifying this ideal equilibrium, ensuring that the selected materials meet the requisite performance criteria and remain economical, assuring the cost-effectiveness and durability of materials.

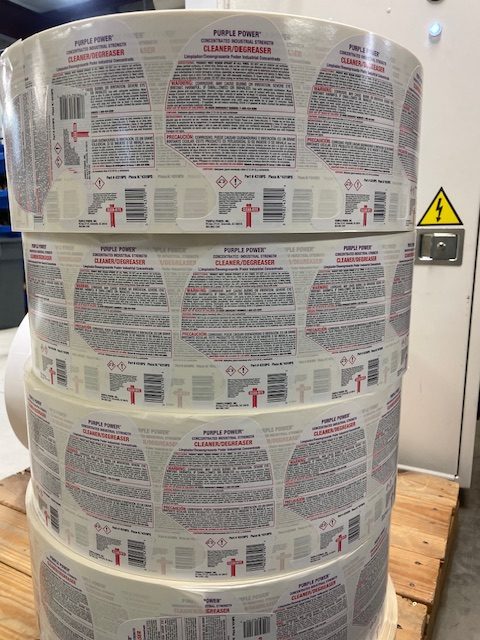

Material selection is critical, where a delicate balance between value and quality must be struck. Clients often seek materials that are both cost-effective and durable. CP&P has demonstrated exceptional proficiency in identifying this ideal equilibrium, ensuring that the selected materials meet the requisite performance criteria and remain economical, assuring the cost-effectiveness and durability of materials. A labeling quote includes a detailed breakdown of all aspects of the label production process. This includes the choice of materials, whether paper or film, the type of laminate or coating to be applied, and the size and configuration of the label rolls. The quote also itemizes any costs associated with tooling, such as tooling required for custom shapes or sizes. This level of detail ensures that clients understand the production process and associated costs, allowing them to make informed decisions that align with their labeling needs and budget constraints.

A labeling quote includes a detailed breakdown of all aspects of the label production process. This includes the choice of materials, whether paper or film, the type of laminate or coating to be applied, and the size and configuration of the label rolls. The quote also itemizes any costs associated with tooling, such as tooling required for custom shapes or sizes. This level of detail ensures that clients understand the production process and associated costs, allowing them to make informed decisions that align with their labeling needs and budget constraints. ISO standards provide a framework for companies to establish, maintain, and implement standardized processes and procedures to ensure that every label meets the highest quality standards. One key aspect of CP&P’s ISO quality system is a checklist integrated into its production process. This checklist serves as a comprehensive guide for press operators and managers. It outlines the critical steps and quality checks needed during the label setup and production process. It covers aspects such as ensuring the correct die-cut, verifying that graphics match the proof, and confirming that the right materials are used.

ISO standards provide a framework for companies to establish, maintain, and implement standardized processes and procedures to ensure that every label meets the highest quality standards. One key aspect of CP&P’s ISO quality system is a checklist integrated into its production process. This checklist serves as a comprehensive guide for press operators and managers. It outlines the critical steps and quality checks needed during the label setup and production process. It covers aspects such as ensuring the correct die-cut, verifying that graphics match the proof, and confirming that the right materials are used.

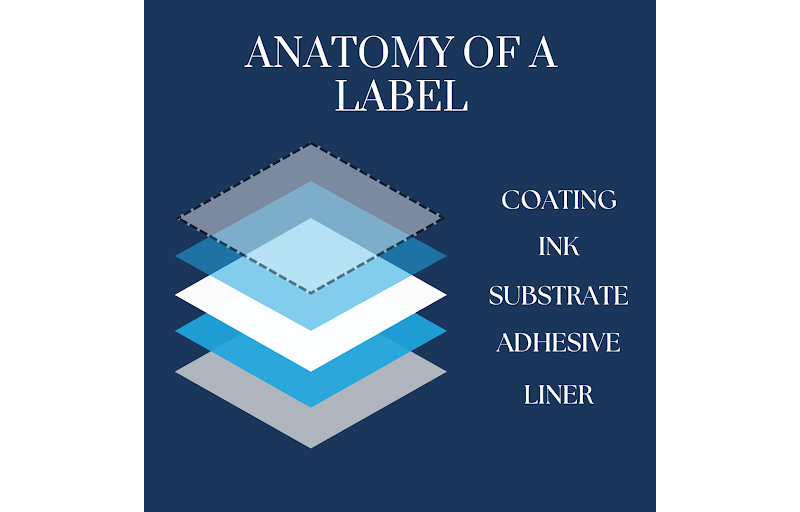

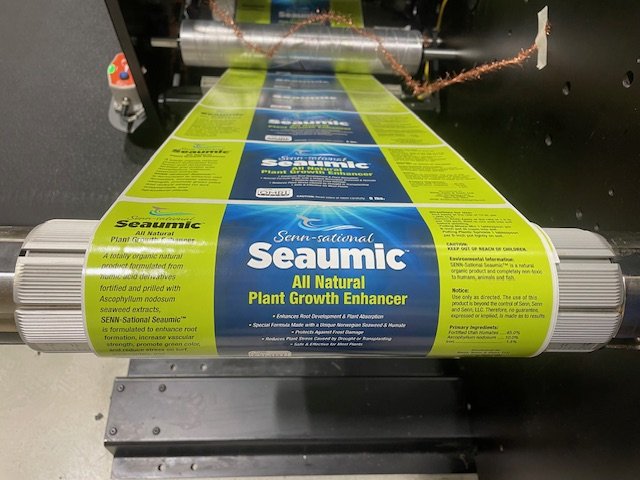

The ink layer beneath the coating is arguably the most significant part of any printed label. It is responsible for conveying all the vital information and aesthetic elements. Choosing the right ink also involves many degrees of customization and variation.

The ink layer beneath the coating is arguably the most significant part of any printed label. It is responsible for conveying all the vital information and aesthetic elements. Choosing the right ink also involves many degrees of customization and variation.  Different substrate materials can be chosen based on cost constraints and the label’s intended use. For instance, a paper label is suitable for general information on a box where resilience and environmental factors are not significant concerns. However, a film label is preferred in outdoor or challenging environments, such as labels on lawnmowers, electrical boxes, or food products that undergo cooking processes. Film labels are more resilient and can withstand harsh conditions, such as extreme temperatures, grease, and moisture. Regarding food labels, additional restrictions and regulations ensure that the materials used are safe for direct food contact and meet FDA standards for food packaging materials. Understanding the impact of substrate choice on label performance is essential in ensuring the label’s longevity and functionality.

Different substrate materials can be chosen based on cost constraints and the label’s intended use. For instance, a paper label is suitable for general information on a box where resilience and environmental factors are not significant concerns. However, a film label is preferred in outdoor or challenging environments, such as labels on lawnmowers, electrical boxes, or food products that undergo cooking processes. Film labels are more resilient and can withstand harsh conditions, such as extreme temperatures, grease, and moisture. Regarding food labels, additional restrictions and regulations ensure that the materials used are safe for direct food contact and meet FDA standards for food packaging materials. Understanding the impact of substrate choice on label performance is essential in ensuring the label’s longevity and functionality. The adhesive of a label is the most technical aspect of labeling, particularly in the context of pressure-sensitive labels, where the bond strength between the label and its substrate is paramount. As such, attention must be given to the adhesive’s characteristics, including its composition, tack, and viscosity. Failure to consider these factors can lead to issues such as label peeling or detachment, which can undermine the label’s functionality and aesthetic appeal.

The adhesive of a label is the most technical aspect of labeling, particularly in the context of pressure-sensitive labels, where the bond strength between the label and its substrate is paramount. As such, attention must be given to the adhesive’s characteristics, including its composition, tack, and viscosity. Failure to consider these factors can lead to issues such as label peeling or detachment, which can undermine the label’s functionality and aesthetic appeal. The last label component is the liner, which serves as a protective backing for the adhesive until it is applied. Typically composed of paper or film, the liner prevents the adhesive from losing its properties before use and ensures optimal performance upon application. While this may seem straightforward, choosing the right liner is crucial, as the wrong liner can lead to lost time, production delays, and wasted material.

The last label component is the liner, which serves as a protective backing for the adhesive until it is applied. Typically composed of paper or film, the liner prevents the adhesive from losing its properties before use and ensures optimal performance upon application. While this may seem straightforward, choosing the right liner is crucial, as the wrong liner can lead to lost time, production delays, and wasted material.

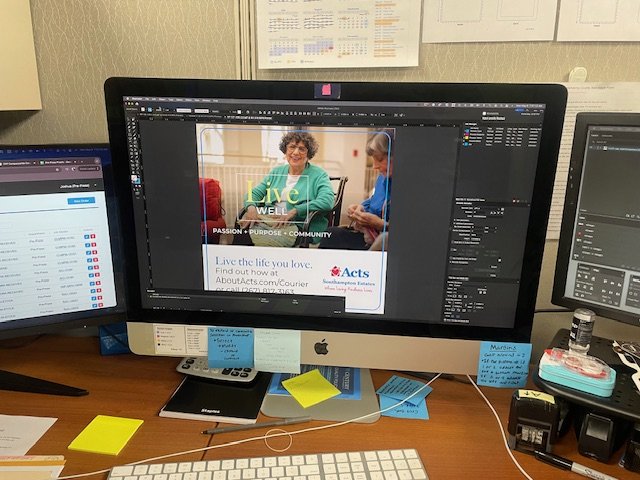

At every pre-press stage, optimization for the best outcome is key. Preparing the artwork starts with the label design for flexo printing. This involves carefully selecting appropriate colors, defining trapping and overprinting settings (which refer to the techniques used to prevent gaps or overlaps between adjacent colors in a print), using printable fonts and point size, and setting up dieline and bleed specifications. A dieline is a graphic element that serves as a template or guide to create a die, which is then used to cut or shape the label substrate.

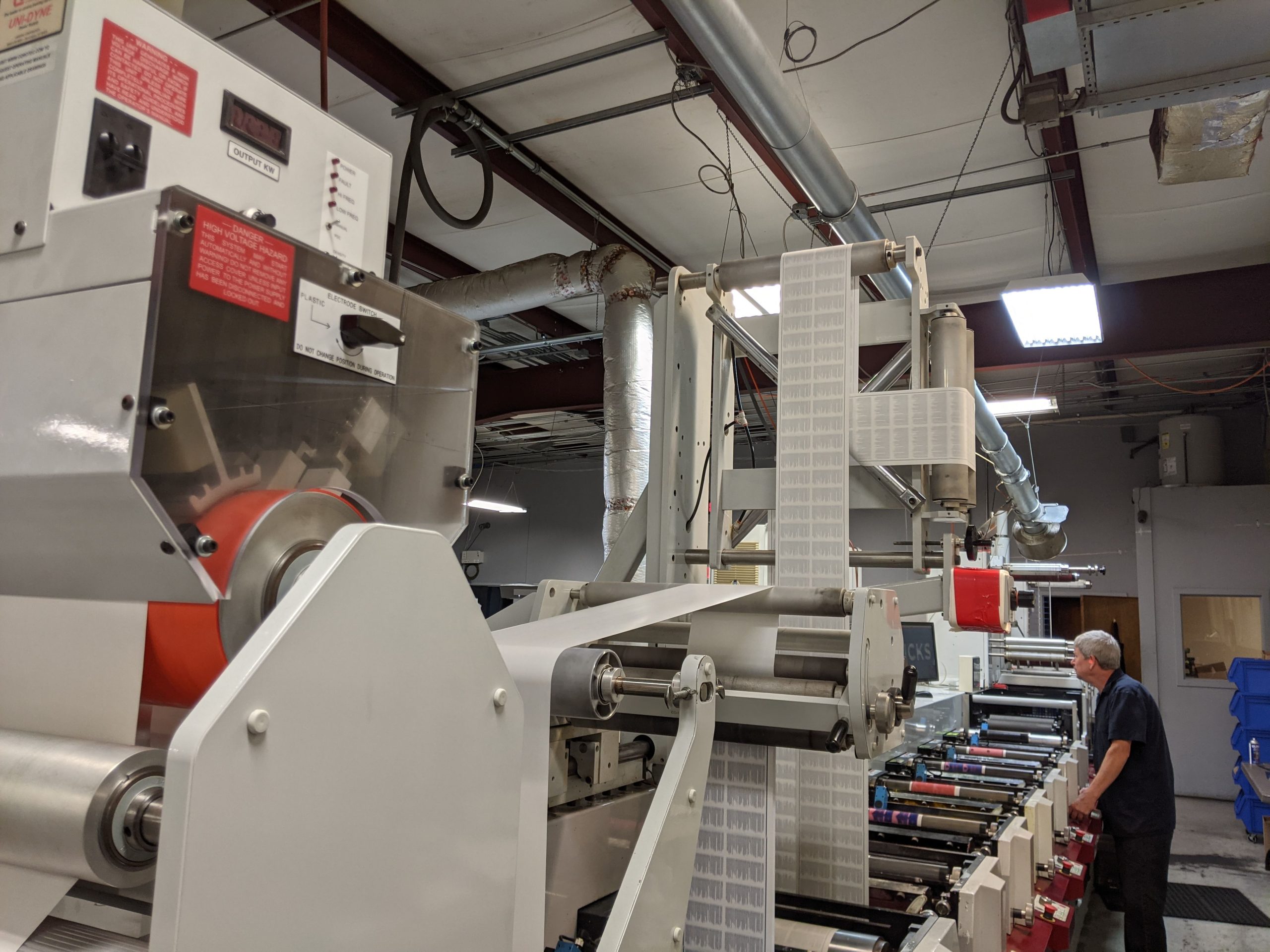

At every pre-press stage, optimization for the best outcome is key. Preparing the artwork starts with the label design for flexo printing. This involves carefully selecting appropriate colors, defining trapping and overprinting settings (which refer to the techniques used to prevent gaps or overlaps between adjacent colors in a print), using printable fonts and point size, and setting up dieline and bleed specifications. A dieline is a graphic element that serves as a template or guide to create a die, which is then used to cut or shape the label substrate. After the prepress steps have been performed, the next order of business is setting up the press. This stage involves choosing the appropriate label substrate based on the application requirements and selecting ink formulations compatible with the preferred substrate. These first steps ensure that the substrate is clean, free from dust or debris, and properly conditioned to minimize static electricity. Ink viscosity adjustments are also conducted to achieve optimal ink transfer and color density to meet desired color specifications.

After the prepress steps have been performed, the next order of business is setting up the press. This stage involves choosing the appropriate label substrate based on the application requirements and selecting ink formulations compatible with the preferred substrate. These first steps ensure that the substrate is clean, free from dust or debris, and properly conditioned to minimize static electricity. Ink viscosity adjustments are also conducted to achieve optimal ink transfer and color density to meet desired color specifications. Next, the press setup agenda involves carefully mounting the flexographic plates onto the printing cylinders to ensure proper alignment with the cutting die. Once the plates are firmly secured using tapes or adhesive materials, it’s time to choose the appropriate anilox rolls based on the desired ink coverage and resolution requirements. Fine-tuning the printing pressure settings to achieve optimal contact between the plates, anilox rolls, and substrate is a prerequisite to avoiding excessive pressure, which can lead to plate distortion, wrong color, or substrate deformation.

Next, the press setup agenda involves carefully mounting the flexographic plates onto the printing cylinders to ensure proper alignment with the cutting die. Once the plates are firmly secured using tapes or adhesive materials, it’s time to choose the appropriate anilox rolls based on the desired ink coverage and resolution requirements. Fine-tuning the printing pressure settings to achieve optimal contact between the plates, anilox rolls, and substrate is a prerequisite to avoiding excessive pressure, which can lead to plate distortion, wrong color, or substrate deformation. Post-press setup is just as important as the prepress and press setup stages. Regular maintenance tasks, such as cleaning ink chambers, doctor blades, and anilox rolls, prevent ink buildup and maintain printing consistency. Replacing worn-out or damaged components as needed is a proactive measure to avoid production disruptions. By performing these tasks regularly, you can keep your equipment in top shape, extend its lifespan, and maximize its performance for each label job.

Post-press setup is just as important as the prepress and press setup stages. Regular maintenance tasks, such as cleaning ink chambers, doctor blades, and anilox rolls, prevent ink buildup and maintain printing consistency. Replacing worn-out or damaged components as needed is a proactive measure to avoid production disruptions. By performing these tasks regularly, you can keep your equipment in top shape, extend its lifespan, and maximize its performance for each label job.