Staying ahead of the curve is essential in the rapidly evolving labeling industry. The Century Printing and Packaging team, led by the expertise of Ben and Neil, has made it their goal to advance with the movement toward RFID (Radio-Frequency Identification) labels. Recently, they attended a conference at Auburn University, where they were immersed in the latest trends and requirements in the RFID labeling sector.

Auburn University’s RFID lab, a beacon of innovation in Radio-Frequency Identification technology, is pivotal in advancing RFID applications across various sectors and helping businesses integrate this technology into their operations effectively. Through its cutting-edge research and hands-on approach, Auburn’s RFID lab is shaping the future of this revolutionary technology and its impact, providing reassurance about the industry’s progress.

Auburn University’s RFID lab, a beacon of innovation in Radio-Frequency Identification technology, is pivotal in advancing RFID applications across various sectors and helping businesses integrate this technology into their operations effectively. Through its cutting-edge research and hands-on approach, Auburn’s RFID lab is shaping the future of this revolutionary technology and its impact, providing reassurance about the industry’s progress.

Ben and Neil traveled to Auburn University’s RFID conference on Wednesday, April 3rd & Thursday, April 4th, in Auburn, Alabama. Their mission was simple: learn from experts in the industry, network with peers, and gain a deeper understanding of how RFID technology is reshaping the packaging landscape. The annual conference at Auburn University is a pivotal event for those looking to stay ahead by gaining the essential expertise to educate their teams and customers. The conference was centered around source tagging and RFID technology, which provided valuable insights into the latest trends, requirements, and best practices in the field. With workshops, presentations, and discussions conducted by leading experts, the two days spent in Auburn offered a comprehensive and informative experience that will be influential in the early and later stages of RFID adoption. One key trend discussed at the conference is the increasing adoption of RFID tags by major retailers like Walmart. These tags are now a requirement for many products, and Auburn University’s RFID lab plays a crucial role in approving packages with RFID tags.

Packaging providers, like CP&P, play a crucial role in this shift towards RFID technology, eventually leading to the natural extinction of the universal, widely accepted barcode. As retailers and other industries increasingly adopt RFID tags for their products, packaging providers are instrumental in integrating these tags into their everyday solutions. The ARC lab prioritizes partnering with packaging providers to ensure their active involvement in the RFID process. This essential collaboration ensures that businesses have a thorough understanding of the process and are prepared to use this information to shape future decisions.

Packaging providers, like CP&P, play a crucial role in this shift towards RFID technology, eventually leading to the natural extinction of the universal, widely accepted barcode. As retailers and other industries increasingly adopt RFID tags for their products, packaging providers are instrumental in integrating these tags into their everyday solutions. The ARC lab prioritizes partnering with packaging providers to ensure their active involvement in the RFID process. This essential collaboration ensures that businesses have a thorough understanding of the process and are prepared to use this information to shape future decisions.

One of the main challenges in adopting RFID technology is the possibility of signal interference with certain products. Materials like metal or products that contain liquids might obstruct or weaken RFID signals, making it hard to read tags accurately. It is essential to recognize that onboarding and verification are critical, particularly in situations involving products with these characteristics.

As exemplified by their attendance at the conference, Century Printing and Packaging is not just keeping pace with industry changes but leading the way. They’ve received positive feedback from previous RFID initiatives and are already seeing customer requests based on their expertise. While at the conference, Ben and Neil engaged with multiple vendors regarding equipment and possible investment in the future. This investment will ensure they can offer customers more integrated and efficient solutions while meeting major retailers’ evolving requirements.

As RFID technology progresses, it’s poised to replace barcodes as a ubiquitous labeling solution. The food market, in particular, is expected to see significant growth in RFID adoption to help with issues such as traceability and rotation. CP&P aims to educate its customers and help them choose the best solutions. By providing cost-effective options and staying on top of future demands, they ensure their customers are well-equipped to meet the challenges of an increasingly RFID-driven market.

Century Printing and Packaging’s commitment to innovation and customer satisfaction sets them apart as a leader in the RFID labeling industry. With their proactive approach and dedication to excellence, they’re well-positioned to meet the ever-changing pressures of the market and provide the best solutions to their customers.

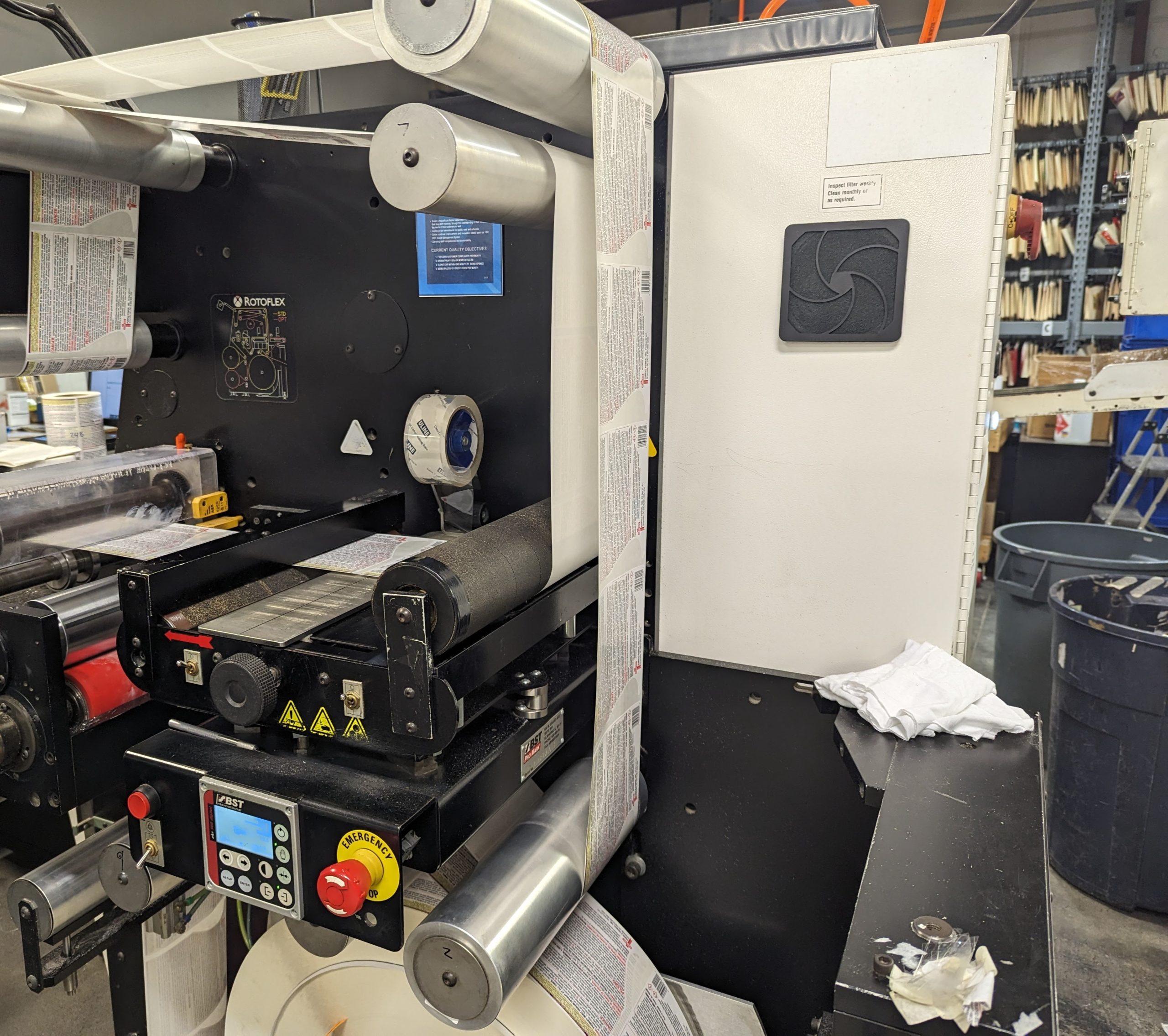

Splicing ensures that labels are seamlessly joined together, whether applied by hand or machine. When labels are machine-applied, the splice must be stronger to withstand the tension from the applicator. In contrast, labels applied by hand require a less intense splice. Understanding how the label will be applied is essential for determining the type of splice needed. This attention to detail ensures that labels are prepared correctly for their intended use, highlighting Century’s commitment to delivering high-quality products tailored to their customers’ needs.

Splicing ensures that labels are seamlessly joined together, whether applied by hand or machine. When labels are machine-applied, the splice must be stronger to withstand the tension from the applicator. In contrast, labels applied by hand require a less intense splice. Understanding how the label will be applied is essential for determining the type of splice needed. This attention to detail ensures that labels are prepared correctly for their intended use, highlighting Century’s commitment to delivering high-quality products tailored to their customers’ needs. Finishing is a vital step in the label printing process that can often get overlooked. However, it’s the final touch that guarantees your labels not only look great but are also ready to be used as intended. At Century Printing and Packaging, each member of the finishing department understands the nuances of this final stage, ensuring even the most complex jobs are handled with precision. The customer’s proof serves as a reference point throughout the process, ensuring that the finished labels match the customer’s specifications. This attention to detail prevents errors and saves time and resources by catching any issues early in the process. By prioritizing quality control and proofs, Century Printing and Packaging demonstrates its commitment to delivering superior results with enhanced appeal for every label.

Finishing is a vital step in the label printing process that can often get overlooked. However, it’s the final touch that guarantees your labels not only look great but are also ready to be used as intended. At Century Printing and Packaging, each member of the finishing department understands the nuances of this final stage, ensuring even the most complex jobs are handled with precision. The customer’s proof serves as a reference point throughout the process, ensuring that the finished labels match the customer’s specifications. This attention to detail prevents errors and saves time and resources by catching any issues early in the process. By prioritizing quality control and proofs, Century Printing and Packaging demonstrates its commitment to delivering superior results with enhanced appeal for every label.

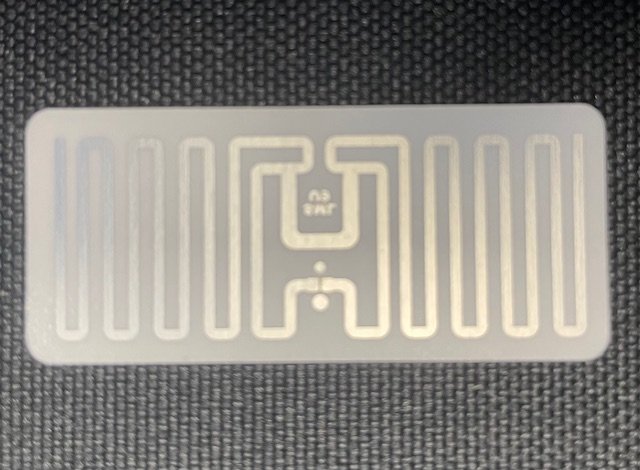

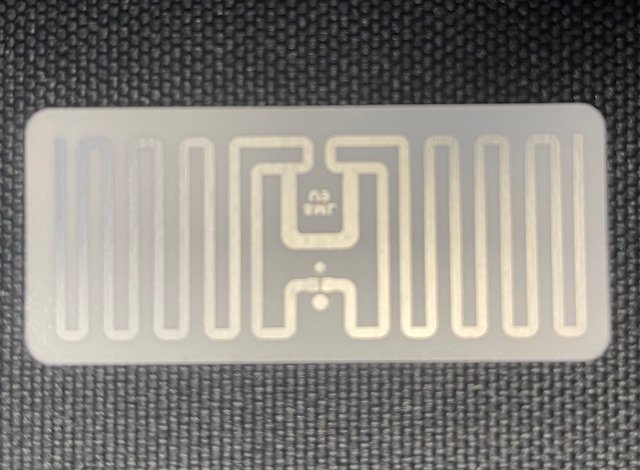

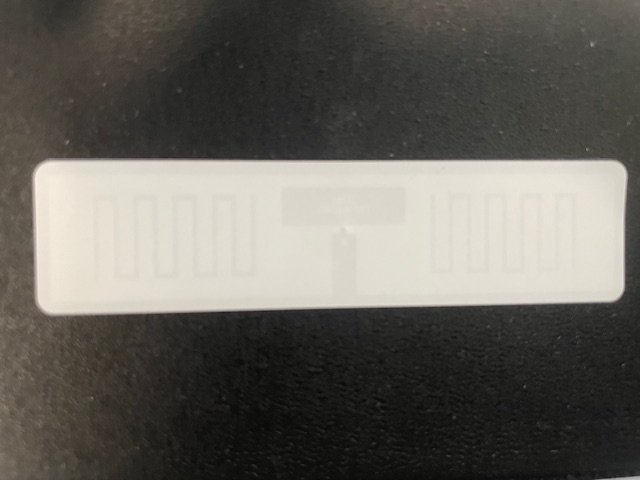

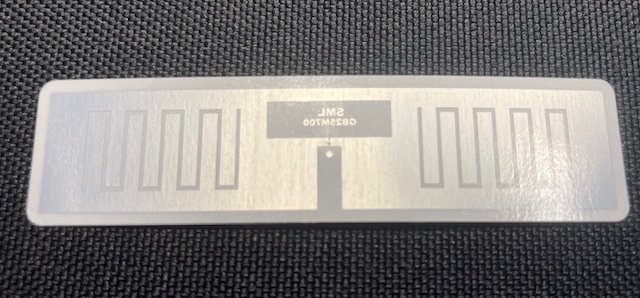

RFID, which stands for Radio Frequency Identification, is a revolutionary technology that provides real-time visibility into inventory levels, making restocking shelves more streamlined and accurate. With RFID, each product or package is equipped with a tag containing an antenna, a transceiver, and a transponder. Employees can quickly scan products with handheld devices or, eventually, through automated systems like robots that constantly take inventory. This instant feedback ensures that items are always in stock, preventing customer frustration and loss of sales.

RFID, which stands for Radio Frequency Identification, is a revolutionary technology that provides real-time visibility into inventory levels, making restocking shelves more streamlined and accurate. With RFID, each product or package is equipped with a tag containing an antenna, a transceiver, and a transponder. Employees can quickly scan products with handheld devices or, eventually, through automated systems like robots that constantly take inventory. This instant feedback ensures that items are always in stock, preventing customer frustration and loss of sales. Finally, the label is applied to the product during the third step. Care and attention to detail are crucial during this process, as any damage to the label or its components can render it useless. For suppliers sending products to retailers like Walmart, damaged RFID labels can lead to rejection and lost business.

Finally, the label is applied to the product during the third step. Care and attention to detail are crucial during this process, as any damage to the label or its components can render it useless. For suppliers sending products to retailers like Walmart, damaged RFID labels can lead to rejection and lost business.

Price

Price