Century Printing & Packaging has been committed to the community for over 25 years and ensures a strong future for manufacturing in the Upstate of South Carolina by hiring high school and college students for part-time positions or internships. One of these students, John Bailey Moore, is a Junior at Wofford College, majoring in finance. He participated in a semester-long program designed to give students like JB opportunities to engage in work experiences outside of mainstream classes.

Interim at Wofford started in 1968 as an opportunity to explore possible career paths and find internship programs and independent studies that pique their interest. It gives students the liberty to explore and innovate, study something new, or leave their comfort zone when the semester schedules aren’t in the way.

In choosing an interim, JB sought first-hand experience and exposure to a real-world business environment. Getting an inside look at the inner workings of a successful organization was what motivated JB to pick an interim in this industry.

John Bailey decided to reach out to CP&P about an opportunity with Ben and Neil. They assigned and presented him with two different tasks to take place over a month during his interim period–

John Bailey decided to reach out to CP&P about an opportunity with Ben and Neil. They assigned and presented him with two different tasks to take place over a month during his interim period–

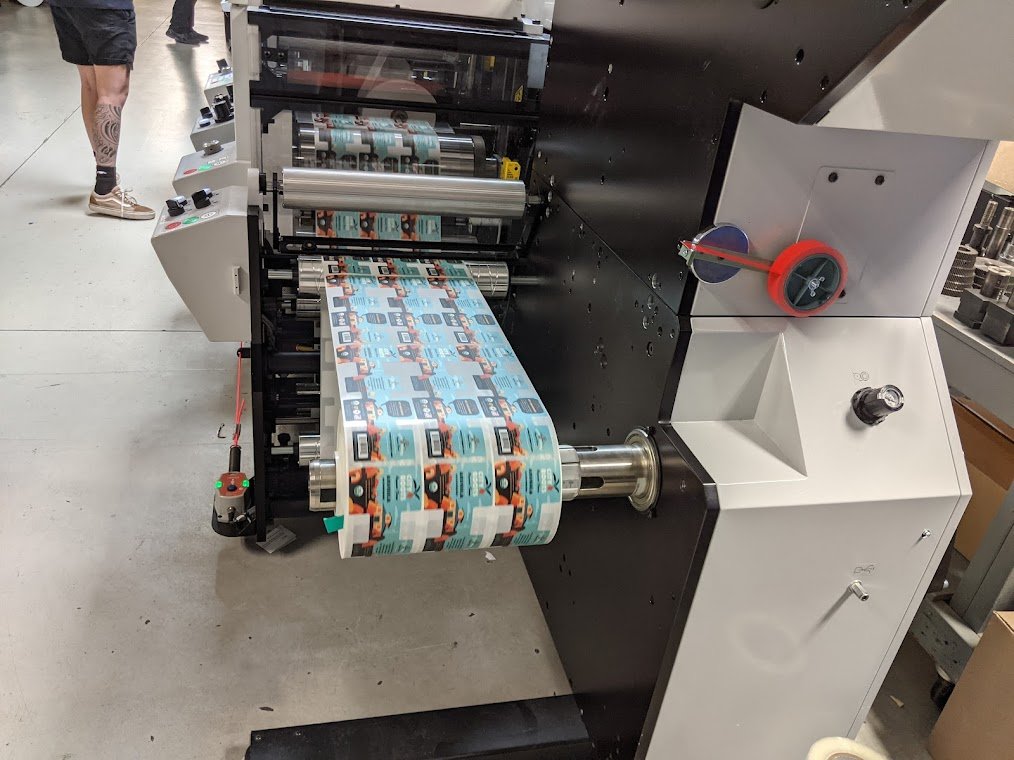

The first was a time study on production equipment. This analytical examination would allow the team to better understand what each employee was doing on the production line and how specific equipment was used precisely during the day. This information is valuable for decision-making in running an efficient business and productive team.

For the first eight days of the study, JB was on the floor at 6 am with the production team. JB’s drive and commitment could be seen from day one– as he started when the machines were turned on and left when they were turned off. In great detail, JB would walk from each press to log the data on the job order, time of day, and press performance.

This pinpointed data was collected 400 times a day, and by the first week, JB had already collected vital metrics and data for the Century Management team. Not only was JB engaging in such a precise process of data collection, but he was also learning about the presses along the way. He learned about the differences between hybrid, digital, and flexo printing purposes and procedures to gain more profound knowledge within his study.

Digital printing is an ideal choice for jobs that require multiple SKUs or multiple versions. This type of printing provides consistency in production with computerized color management. So that label to label, the colors are uniform with no variation between operators.

Flexo printing is fit for longer runs with a minimal number of SKUs. It uses printing plates and inks that must be changed for each job requirement, thus requiring more manual work and time for setup.

In hybrid printing, the two types of print are combined, bridging the gap between them. The hybrid model can produce longer runs and higher label counts while maintaining consistency, repeatability, and efficiency benefits from job to job.

After the data was collected, JB diligently took the weighted averages of each data set and turned them into actionable numbers for Ben and Neil. Looking at the daily averages, weekly averages, and specific data points, like which machine ran the longest, gave CP&P vital statistics and takeaways.

The second section of JB’s project involved an in-depth water usage analysis. This task asked, “how much water was being used daily?” As businesses take a more environmentally friendly approach to usage and waste, the importance of water sits near the top of the list.

JB examined how the team used water after jobs and where the areas for reducing water were within the processes throughout the day. Four of 5 presses owned by CP&P use water-based inks, primarily what the water and washouts are for.

JB would check in with the managers every time they’d run the water system or turn on the sinks and, in doing so– developed an estimate of how much water the sinks could hold and how full they were at the end of each day.

As a result of JB’s study, CP&P has done two things to improve the efficiency of their business as they continue to scale. Ben and Neil decided to purchase a parts washer, which is now routinely being implemented to recycle water so that the team uses less water when cleaning parts at the end of a production day. This has resulted in cost savings, increased efficiency, and better use of water as a resource.

Because of the numbers that JB collected while on the production line, Ben and Neil can now integrate real-time data into their pricing models. This specificity of his data has provided better insights to pull from when determining current and future business and financial endeavors. The Century Management team is currently integrating this real-world data into their pricing models to ensure their costs are accurate and they can offer customers competitive pricing.

Because of the numbers that JB collected while on the production line, Ben and Neil can now integrate real-time data into their pricing models. This specificity of his data has provided better insights to pull from when determining current and future business and financial endeavors. The Century Management team is currently integrating this real-world data into their pricing models to ensure their costs are accurate and they can offer customers competitive pricing.

“If my data can help Ben and Neil better price job orders, I feel like I contributed to his business,” John Bailey said as he realized how much relevancy his data and study brought to the overall operations of CP&P. During this season of inflation, obtaining real-world data over estimations is crucial to maintain realistic costs and remain dialed into the current economy.

According to JB, the conversations with Ben and Neil were more valuable and relevant than any class he had taken. John Bailey enjoyed asking questions about the business and the “why” behind Ben and Neil’s decisions while he was there and getting thoughtful, in-demand answers in return.

“My favorite part was when I got to tie what I was looking at for 7, 8, 9 hours a day, and how it applied to my finance major,” says JB.

John Bailey focused his attention on all aspects of Century’s business operations that make it a success, including its morning huddles and how its employees maintain high business standards every day. From the production meetings to the sales meetings, JB saw firsthand how Ben and Neil ensured that quality was the same on every single job. JB appreciated that anyone in the office, on the floor, or running the presses was kind and open to helping and explaining different aspects of the business to him.

Ben and Neil are building a vision for their employees to sell to their customers. Seeing that vision come to life was a significant takeaway from JB’s interim experience at CP&P.

Being a part of the surrounding community is a priority for Ben and Neil as they work to stay connected with the next generation of young professionals. CP&P will continue to offer opportunities like this to students in the area. Exposure and experience are invaluable to anyone looking to uplevel their career or personal development like JB.

Century Printing and Packaging is still a family business, locally owned and operated that believes in building relationships with customers in order to meet or exceed their expectations by focussing on customer support and service while implementing the most innovative and creative printing and packaging technology available.

Century Printing and Packaging is still a family business, locally owned and operated that believes in building relationships with customers in order to meet or exceed their expectations by focussing on customer support and service while implementing the most innovative and creative printing and packaging technology available.

Providing higher sustainability and product wrapping for regional dairy and butter producers is something Century Printing and Packaging has made a significant commitment to for the industry. Butter producers need to ensure that their product can be protected from light which affects and progresses product aging. Water-based inks are good for food safe products. Century has a 25 year track record of using water based inks which are environmentally friendly.

Providing higher sustainability and product wrapping for regional dairy and butter producers is something Century Printing and Packaging has made a significant commitment to for the industry. Butter producers need to ensure that their product can be protected from light which affects and progresses product aging. Water-based inks are good for food safe products. Century has a 25 year track record of using water based inks which are environmentally friendly. Regional dairies contact us today about possibilities for your butter products and wrapping. We look forward to seeing you at the IDDBA in June and showing off this cutting-edge wrapping material. There is nothing like this material in the U.S. for dairy and butter producers so don’t miss the opportunity to engage and contact us regarding the possibilities for your dairy. Stand out and emerge from the competition with this incredible wrap that preserves your product.

Regional dairies contact us today about possibilities for your butter products and wrapping. We look forward to seeing you at the IDDBA in June and showing off this cutting-edge wrapping material. There is nothing like this material in the U.S. for dairy and butter producers so don’t miss the opportunity to engage and contact us regarding the possibilities for your dairy. Stand out and emerge from the competition with this incredible wrap that preserves your product. Ben Waldrop

Ben Waldrop

Neil, how did Century Printing and Packaging Begin?

Neil, how did Century Printing and Packaging Begin? 25 years ago did you ever think it would be on this scale?

25 years ago did you ever think it would be on this scale? The latest major change in the industry is digital printing. It has been around for about ten years, but within the last five years it has escalated in terms of speed, quality and the ability to print more substrates has allowed it to really explode, which has pros and cons. Some work can’t be done on flexo and has to be done on a digital press. Traditionally, digital has been a higher cost in long production runs but the prices are coming down which is why we are securing new equipment. To be competitive we’ve got to be able to produce the quality at the price our customers need.

The latest major change in the industry is digital printing. It has been around for about ten years, but within the last five years it has escalated in terms of speed, quality and the ability to print more substrates has allowed it to really explode, which has pros and cons. Some work can’t be done on flexo and has to be done on a digital press. Traditionally, digital has been a higher cost in long production runs but the prices are coming down which is why we are securing new equipment. To be competitive we’ve got to be able to produce the quality at the price our customers need. What are some of the things you are seeing in the future of the printing and packaging industry?

What are some of the things you are seeing in the future of the printing and packaging industry? So tell us about your family

So tell us about your family