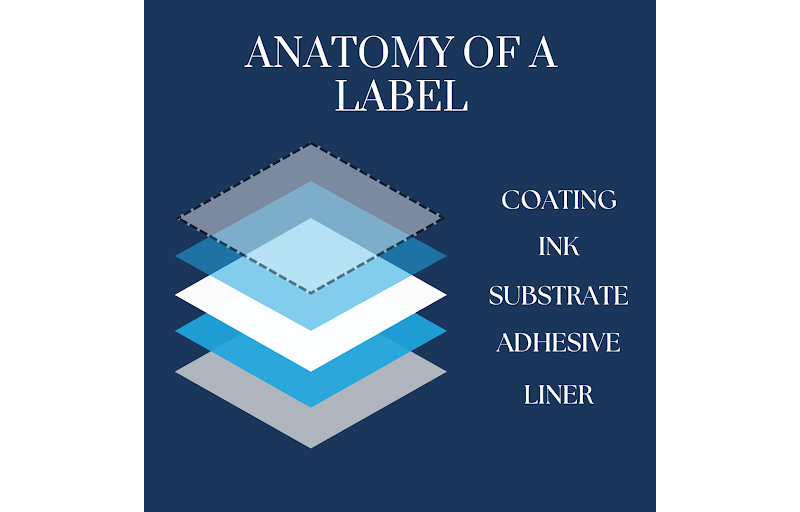

Understanding the breakdown of a label is important to visualize how each layer works together. A label comprises five main components: the coating, ink, substrate, adhesive, and liner. The topmost layer of the label, the coating, sits on top of the ink to enhance its appearance and color. The coating can be either laminate or varnish. Laminate provides enhanced protection, offers a more comprehensive barrier, and acts like a giant piece of masking tape, enforcing strength and the ability to last for long periods of time. In comparison, varnish provides the flexibility of being applied to a selective part of the label if required. Varnish coatings can be water-based or UV-based, offering different looks and feel depending on the customer’s preference.

The ink layer beneath the coating is arguably the most significant part of any printed label. It is responsible for conveying all the vital information and aesthetic elements. Choosing the right ink also involves many degrees of customization and variation. You can learn more about the differences between water-based and UV inks here.

The ink layer beneath the coating is arguably the most significant part of any printed label. It is responsible for conveying all the vital information and aesthetic elements. Choosing the right ink also involves many degrees of customization and variation. You can learn more about the differences between water-based and UV inks here.

The next layer is the substrate, which refers to the material on which the label is printed. It plays a critical role in determining the label’s performance and durability. The substrate affects the label’s ability to withstand environmental conditions such as contact with liquid, heat, and light exposure. It also impacts the label’s ability to adhere to different surfaces and maintain its original look over time.

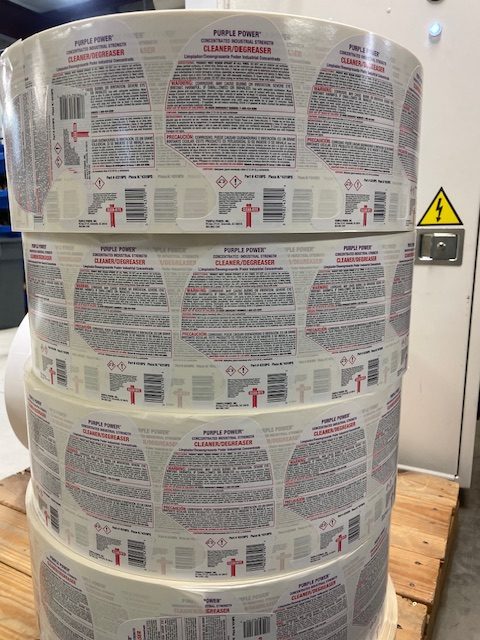

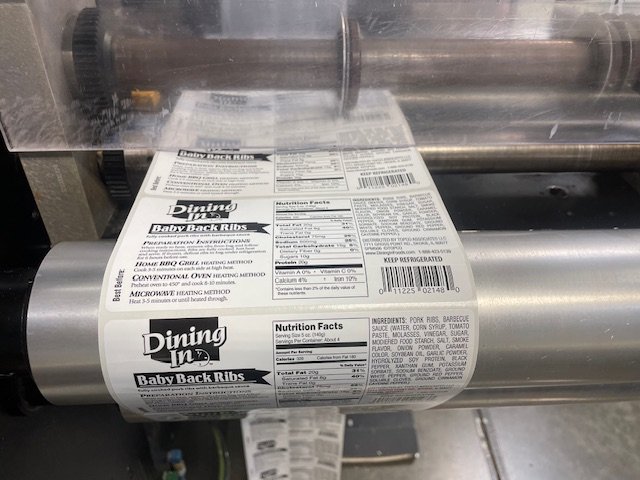

Different substrate materials can be chosen based on cost constraints and the label’s intended use. For instance, a paper label is suitable for general information on a box where resilience and environmental factors are not significant concerns. However, a film label is preferred in outdoor or challenging environments, such as labels on lawnmowers, electrical boxes, or food products that undergo cooking processes. Film labels are more resilient and can withstand harsh conditions, such as extreme temperatures, grease, and moisture. Regarding food labels, additional restrictions and regulations ensure that the materials used are safe for direct food contact and meet FDA standards for food packaging materials. Understanding the impact of substrate choice on label performance is essential in ensuring the label’s longevity and functionality.

Different substrate materials can be chosen based on cost constraints and the label’s intended use. For instance, a paper label is suitable for general information on a box where resilience and environmental factors are not significant concerns. However, a film label is preferred in outdoor or challenging environments, such as labels on lawnmowers, electrical boxes, or food products that undergo cooking processes. Film labels are more resilient and can withstand harsh conditions, such as extreme temperatures, grease, and moisture. Regarding food labels, additional restrictions and regulations ensure that the materials used are safe for direct food contact and meet FDA standards for food packaging materials. Understanding the impact of substrate choice on label performance is essential in ensuring the label’s longevity and functionality.

The adhesive of a label is the most technical aspect of labeling, particularly in the context of pressure-sensitive labels, where the bond strength between the label and its substrate is paramount. As such, attention must be given to the adhesive’s characteristics, including its composition, tack, and viscosity. Failure to consider these factors can lead to issues such as label peeling or detachment, which can undermine the label’s functionality and aesthetic appeal.

The adhesive of a label is the most technical aspect of labeling, particularly in the context of pressure-sensitive labels, where the bond strength between the label and its substrate is paramount. As such, attention must be given to the adhesive’s characteristics, including its composition, tack, and viscosity. Failure to consider these factors can lead to issues such as label peeling or detachment, which can undermine the label’s functionality and aesthetic appeal.

The adhesive’s performance is influenced by factors such as how quickly it needs to stick and the environmental conditions it will endure. It is essential to use adhesives rated for specific temperature ranges during their application and use. Labels may need to be applied at one temperature but then subjected to different temperatures, such as flash freezing. The adhesive must withstand these temperature changes without losing its ability to stick or causing the label to crack and peel. A label that fails to adhere properly can negatively impact the product’s perceived quality, potentially leading to decreased sales.

The last label component is the liner, which serves as a protective backing for the adhesive until it is applied. Typically composed of paper or film, the liner prevents the adhesive from losing its properties before use and ensures optimal performance upon application. While this may seem straightforward, choosing the right liner is crucial, as the wrong liner can lead to lost time, production delays, and wasted material.

The last label component is the liner, which serves as a protective backing for the adhesive until it is applied. Typically composed of paper or film, the liner prevents the adhesive from losing its properties before use and ensures optimal performance upon application. While this may seem straightforward, choosing the right liner is crucial, as the wrong liner can lead to lost time, production delays, and wasted material.

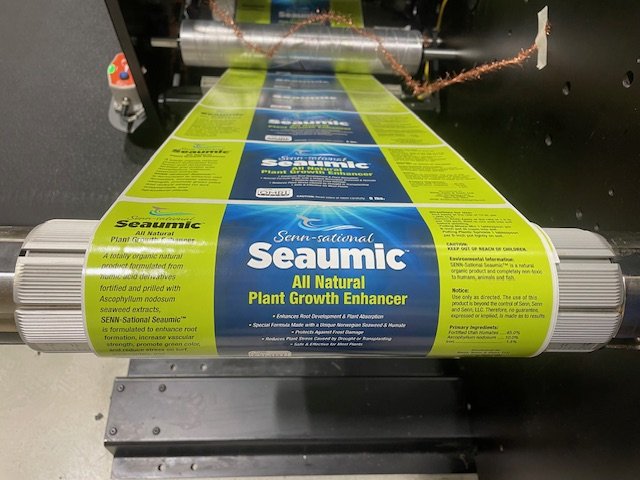

Century Printing and Packaging is passionate about staying at the forefront of advancements in labeling technology. Recent developments have been transformative, including the creation of thinner, higher-performance films that offer superior toughness and performance. The emergence of new adhesives specifically designed for harsh environments, such as those with high humidity, has opened up new possibilities for label production. Advancements in die-cutting tools have led to more precise and efficient label production.

The final product of a label is a testament to the expertise and meticulous attention to detail of label manufacturers. Selecting the appropriate coatings, inks, substrates, adhesives, and liners for each client is a complex task that requires deep understanding and experience. Century Printing and Packaging, with a 27-year track record in the labeling industry, has developed a sterling reputation and proven expertise in choosing and producing labels at a high level. Their comprehensive understanding of label components and longstanding commitment to exceeding customer expectations make them the best choice when looking for a label partner.

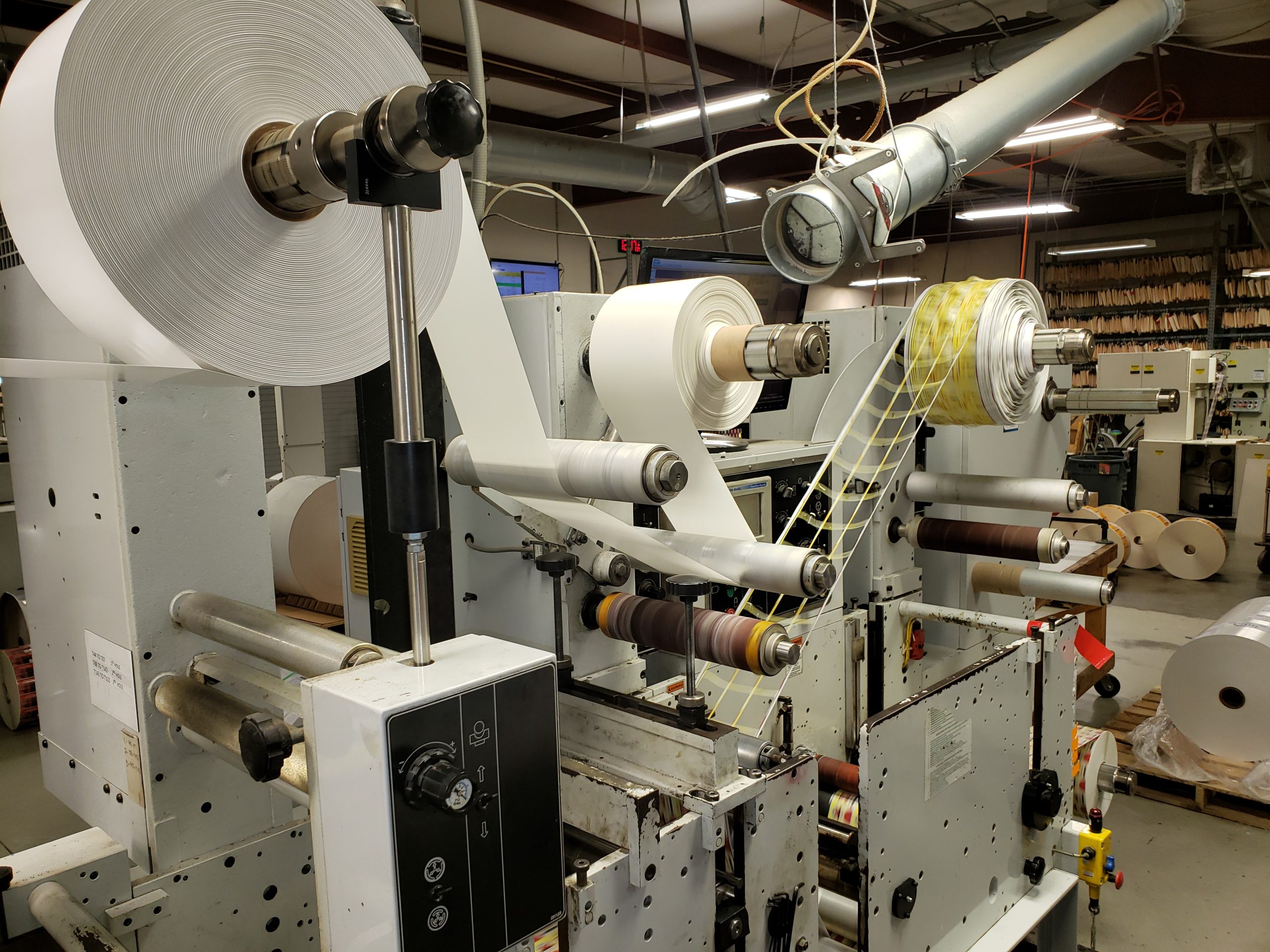

At every pre-press stage, optimization for the best outcome is key. Preparing the artwork starts with the label design for flexo printing. This involves carefully selecting appropriate colors, defining trapping and overprinting settings (which refer to the techniques used to prevent gaps or overlaps between adjacent colors in a print), using printable fonts and point size, and setting up dieline and bleed specifications. A dieline is a graphic element that serves as a template or guide to create a die, which is then used to cut or shape the label substrate.

At every pre-press stage, optimization for the best outcome is key. Preparing the artwork starts with the label design for flexo printing. This involves carefully selecting appropriate colors, defining trapping and overprinting settings (which refer to the techniques used to prevent gaps or overlaps between adjacent colors in a print), using printable fonts and point size, and setting up dieline and bleed specifications. A dieline is a graphic element that serves as a template or guide to create a die, which is then used to cut or shape the label substrate. After the prepress steps have been performed, the next order of business is setting up the press. This stage involves choosing the appropriate label substrate based on the application requirements and selecting ink formulations compatible with the preferred substrate. These first steps ensure that the substrate is clean, free from dust or debris, and properly conditioned to minimize static electricity. Ink viscosity adjustments are also conducted to achieve optimal ink transfer and color density to meet desired color specifications.

After the prepress steps have been performed, the next order of business is setting up the press. This stage involves choosing the appropriate label substrate based on the application requirements and selecting ink formulations compatible with the preferred substrate. These first steps ensure that the substrate is clean, free from dust or debris, and properly conditioned to minimize static electricity. Ink viscosity adjustments are also conducted to achieve optimal ink transfer and color density to meet desired color specifications. Next, the press setup agenda involves carefully mounting the flexographic plates onto the printing cylinders to ensure proper alignment with the cutting die. Once the plates are firmly secured using tapes or adhesive materials, it’s time to choose the appropriate anilox rolls based on the desired ink coverage and resolution requirements. Fine-tuning the printing pressure settings to achieve optimal contact between the plates, anilox rolls, and substrate is a prerequisite to avoiding excessive pressure, which can lead to plate distortion, wrong color, or substrate deformation.

Next, the press setup agenda involves carefully mounting the flexographic plates onto the printing cylinders to ensure proper alignment with the cutting die. Once the plates are firmly secured using tapes or adhesive materials, it’s time to choose the appropriate anilox rolls based on the desired ink coverage and resolution requirements. Fine-tuning the printing pressure settings to achieve optimal contact between the plates, anilox rolls, and substrate is a prerequisite to avoiding excessive pressure, which can lead to plate distortion, wrong color, or substrate deformation. Post-press setup is just as important as the prepress and press setup stages. Regular maintenance tasks, such as cleaning ink chambers, doctor blades, and anilox rolls, prevent ink buildup and maintain printing consistency. Replacing worn-out or damaged components as needed is a proactive measure to avoid production disruptions. By performing these tasks regularly, you can keep your equipment in top shape, extend its lifespan, and maximize its performance for each label job.

Post-press setup is just as important as the prepress and press setup stages. Regular maintenance tasks, such as cleaning ink chambers, doctor blades, and anilox rolls, prevent ink buildup and maintain printing consistency. Replacing worn-out or damaged components as needed is a proactive measure to avoid production disruptions. By performing these tasks regularly, you can keep your equipment in top shape, extend its lifespan, and maximize its performance for each label job.

Auburn University’s RFID lab, a beacon of innovation in Radio-Frequency Identification technology, is pivotal in advancing RFID applications across various sectors and helping businesses integrate this technology into their operations effectively. Through its cutting-edge research and hands-on approach, Auburn’s RFID lab is shaping the future of this revolutionary technology and its impact, providing reassurance about the industry’s progress.

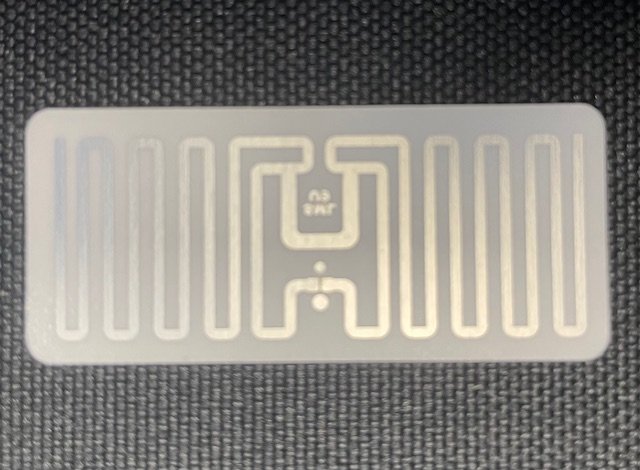

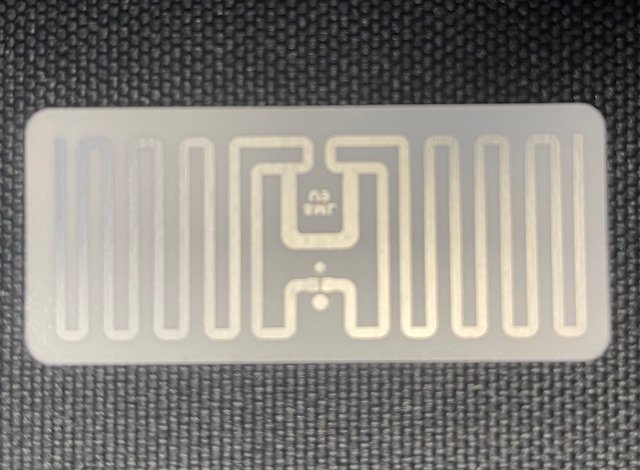

Auburn University’s RFID lab, a beacon of innovation in Radio-Frequency Identification technology, is pivotal in advancing RFID applications across various sectors and helping businesses integrate this technology into their operations effectively. Through its cutting-edge research and hands-on approach, Auburn’s RFID lab is shaping the future of this revolutionary technology and its impact, providing reassurance about the industry’s progress. Packaging providers, like CP&P, play a crucial role in this shift towards RFID technology, eventually leading to the natural extinction of the universal, widely accepted barcode. As retailers and other industries increasingly adopt RFID tags for their products, packaging providers are instrumental in integrating these tags into their everyday solutions. The ARC lab prioritizes partnering with packaging providers to ensure their active involvement in the RFID process. This essential collaboration ensures that businesses have a thorough understanding of the process and are prepared to use this information to shape future decisions.

Packaging providers, like CP&P, play a crucial role in this shift towards RFID technology, eventually leading to the natural extinction of the universal, widely accepted barcode. As retailers and other industries increasingly adopt RFID tags for their products, packaging providers are instrumental in integrating these tags into their everyday solutions. The ARC lab prioritizes partnering with packaging providers to ensure their active involvement in the RFID process. This essential collaboration ensures that businesses have a thorough understanding of the process and are prepared to use this information to shape future decisions.

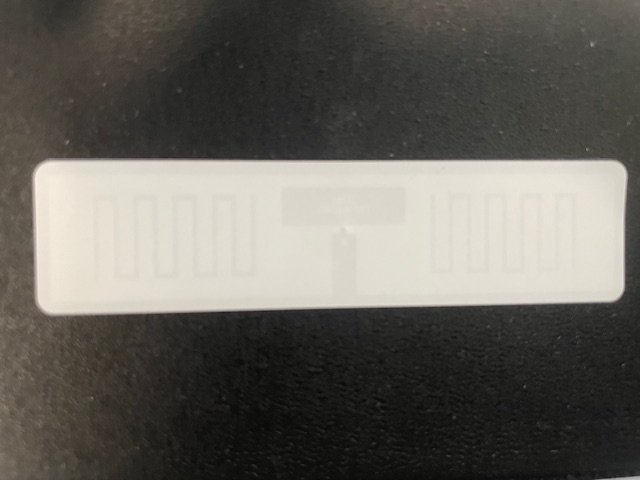

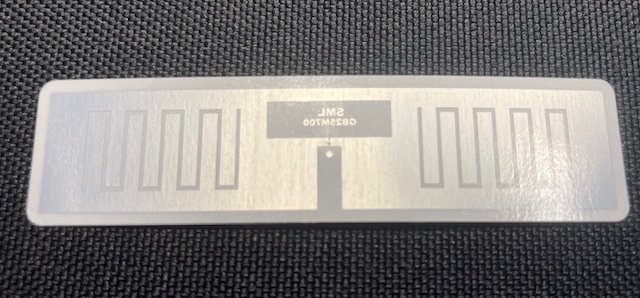

RFID, which stands for Radio Frequency Identification, is a revolutionary technology that provides real-time visibility into inventory levels, making restocking shelves more streamlined and accurate. With RFID, each product or package is equipped with a tag containing an antenna, a transceiver, and a transponder. Employees can quickly scan products with handheld devices or, eventually, through automated systems like robots that constantly take inventory. This instant feedback ensures that items are always in stock, preventing customer frustration and loss of sales.

RFID, which stands for Radio Frequency Identification, is a revolutionary technology that provides real-time visibility into inventory levels, making restocking shelves more streamlined and accurate. With RFID, each product or package is equipped with a tag containing an antenna, a transceiver, and a transponder. Employees can quickly scan products with handheld devices or, eventually, through automated systems like robots that constantly take inventory. This instant feedback ensures that items are always in stock, preventing customer frustration and loss of sales. Finally, the label is applied to the product during the third step. Care and attention to detail are crucial during this process, as any damage to the label or its components can render it useless. For suppliers sending products to retailers like Walmart, damaged RFID labels can lead to rejection and lost business.

Finally, the label is applied to the product during the third step. Care and attention to detail are crucial during this process, as any damage to the label or its components can render it useless. For suppliers sending products to retailers like Walmart, damaged RFID labels can lead to rejection and lost business.

One major factor that has affected the beer industry is the shortage of glass. Coming out of the pandemic, supply chain issues have resulted in many beer brands opting to purchase unprinted cans and add their own labels as needed. This not only offers more flexibility in terms of branding and design, but it also allows breweries to save money by only ordering the exact amount of cans they need at any given time.

One major factor that has affected the beer industry is the shortage of glass. Coming out of the pandemic, supply chain issues have resulted in many beer brands opting to purchase unprinted cans and add their own labels as needed. This not only offers more flexibility in terms of branding and design, but it also allows breweries to save money by only ordering the exact amount of cans they need at any given time.